Secondary sedimentation tank system capable of improving organic wastewater effluent quality and processing method

A technology of secondary sedimentation tank and effluent quality, applied in sedimentation tank, feeding/discharging device of sedimentation tank, etc., can solve the problems of water turbidity, affecting effluent quality, unfavorable separation of water and floating mud, etc., to improve interception effect, the effect of improving water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

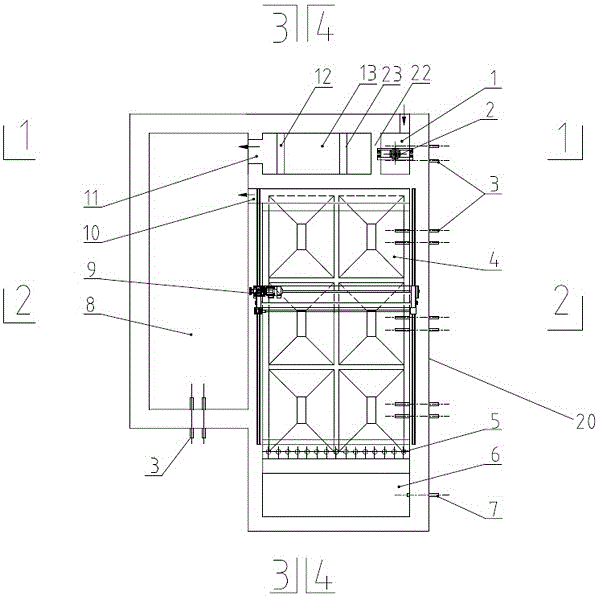

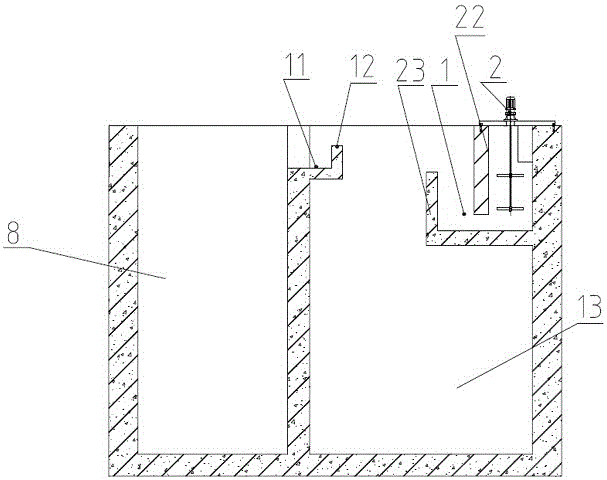

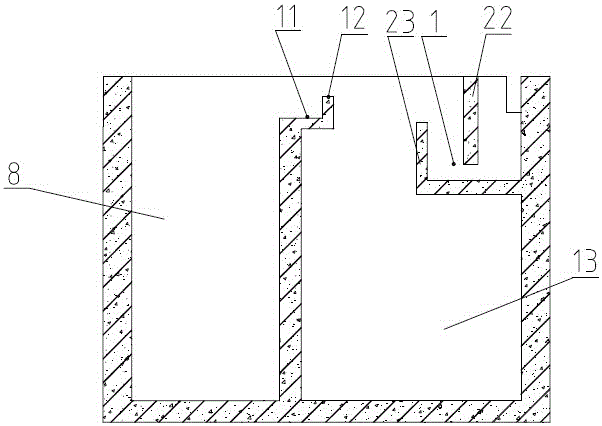

[0040] Such as Figure 1-6 The shown secondary settling tank system that can improve the quality of the effluent is an embodiment of the present invention, including a coagulation tank, a secondary settling tank 20, an effluent collection tank 6 and a sludge thickening tank 8, and the four tanks can be independently set up. In order to save land, in this embodiment, the coagulation tank, the secondary sedimentation tank 20, the outlet water collection tank 6 and the sludge thickening tank 8 are arranged close to each other. Wherein, the coagulation tank, the secondary sedimentation tank 20 and the outlet water collection tank 6 are sequentially connected along the water flow direction. The coagulation tank and the secondary sedimentation tank 20 are connected by a rectifying wall 19 with holes, and the outlet water collection tank 6 is located at the tail of the secondary sedimentation tank 20 and is connected with the secondary sedimentation tank 20 through a partition wall ...

Embodiment 2

[0045] When the biochemically treated wastewater enters the reaction hopper 1 of the coagulation tank, the mixer 2 is started, and the coagulant dosing system adds an appropriate amount of coagulant at the same time, and the flocculant dosing system simultaneously adds an appropriate amount of flocculant. The waste water after the coagulation reaction in 1 overflows into the water distribution tank 13, then passes through the perforated rectifying wall 19 and enters the buffer zone of the secondary sedimentation tank 20, then reaches the sedimentation area for mud-water separation, and reaches the tail of the secondary sedimentation tank 20 Pass through the overflow weir hole 5 and the filter screen, and then overflow into the effluent sump 6.

[0046] After the mud-water separation in the sedimentation area, most of the sludge can settle to the mud collecting bucket 4 at the bottom of the tank, and some flocs become floating mud and float on the water surface. Carry out 1-2 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com