Method for deep removal of zero valence mercury in mercury smelting flue gas

A technology for smelting flue gas and zero-valent mercury. It is applied in separation methods, chemical instruments and methods, and other chemical processes. It can solve the problems of high volatility, difficult removal, and low water solubility, and achieve moderate price and easy removal. effect, high removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

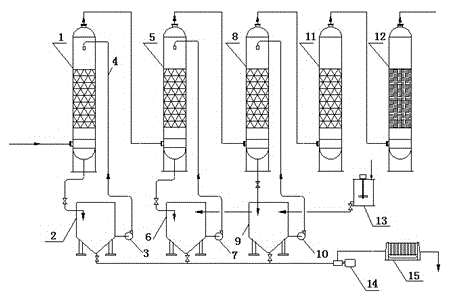

[0035] The method of deep mercury removal from mercury smelting flue gas (the process is as follows figure 1 shown), the details are as follows:

[0036] (1) The flue gas to be treated in this embodiment is mercury smelting flue gas, and the flue gas volume is 3500m 3 / h, Hg in flue gas at furnace mouth: 4-7mg / m3 After the smelting flue gas passes through the dust removal tower, the temperature of the flue gas is cooled to below 45°C;

[0037] (2) The modified activated carbon was prepared by the following method: weigh the activated carbon, wash it three times with deionized water at 20°C, dry it at 105°C for 5 hours, and impregnate the activated carbon with 0.1mol / L ferric chloride solution at room temperature 20 hours, during the impregnation process and continuous stirring; the filtered activated carbon was dried at 105°C for 5 hours, and then roasted at 200°C for 3 hours in a muffle furnace.

[0038] (3) Atomize the sodium hypochlorite solution with a mass percentage co...

Embodiment 2

[0044] The method of deep mercury removal from lead smelting flue gas, the specific content is as follows:

[0045] (1) The flue gas to be treated in this embodiment is mercury smelting flue gas, and the flue gas volume is 5000m 3 / h, Hg in flue gas at furnace mouth: 1-3mg / m 3 After the smelting flue gas passes through the dust removal tower, the temperature of the flue gas is cooled to below 45°C;

[0046] (2) The modified activated carbon is prepared by the following method: Weigh the activated carbon, wash it with 80°C deionized water for 5 times, dry it at 110°C for 12 hours, and wash it with 0.2mol / L ferric chloride solution at room temperature The activated carbon was impregnated for 30 hours, and stirred continuously during the impregnation process; the filtered activated carbon was dried at 110°C for 12 hours, and then roasted in a muffle furnace at 400°C for 8 hours.

[0047] (3) Atomize the sodium hypochlorite solution with a mass percentage concentration of 4% (so...

Embodiment 3

[0053] The method of deep mercury removal from mercury refining flue gas, the specific content is as follows:

[0054] (1) The flue gas to be treated in this embodiment is mercury smelting flue gas, and the flue gas volume is 2000m 3 / h, Hg in flue gas at furnace mouth: 5-8mg / m 3 After the smelting flue gas passes through the dust removal tower, the temperature of the flue gas is cooled to below 45°C;

[0055] (2) The modified activated carbon is prepared by the following method: Weigh the activated carbon, wash it with 50°C deionized water for 4 times, dry it at 107°C for 8 hours, and wash it with 0.15mol / L ferric chloride solution at room temperature Immerse the activated carbon for 25 hours, and keep stirring during the impregnation process; the filtered activated carbon is dried at 107°C for 8 hours, and then roasted at 300°C for 6 hours in a muffle furnace.

[0056] (3) Atomize the sodium hypochlorite solution with a mass percentage concentration of 5% (sodium chloride ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com