Edible fungi culture medium crushing equipment

A technology for crushing equipment and culturing materials, applied in grain processing and other directions, can solve the problems of increased equipment cost, high price, unstable motor operation, etc., and achieve the effect of improving material fineness and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

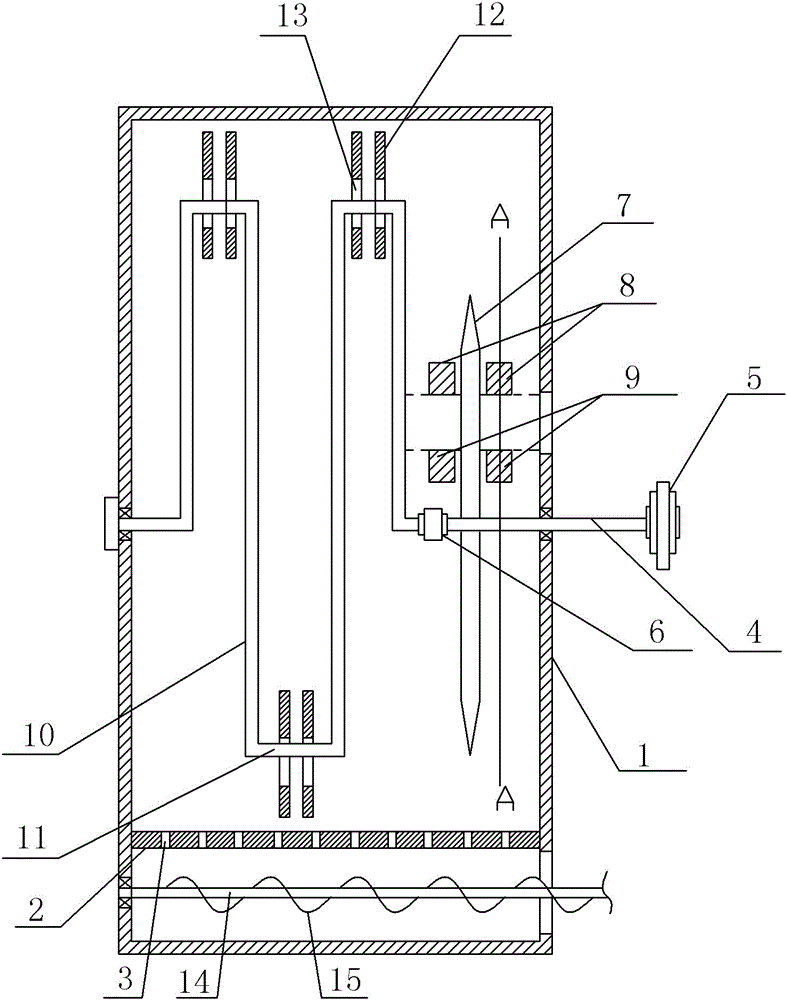

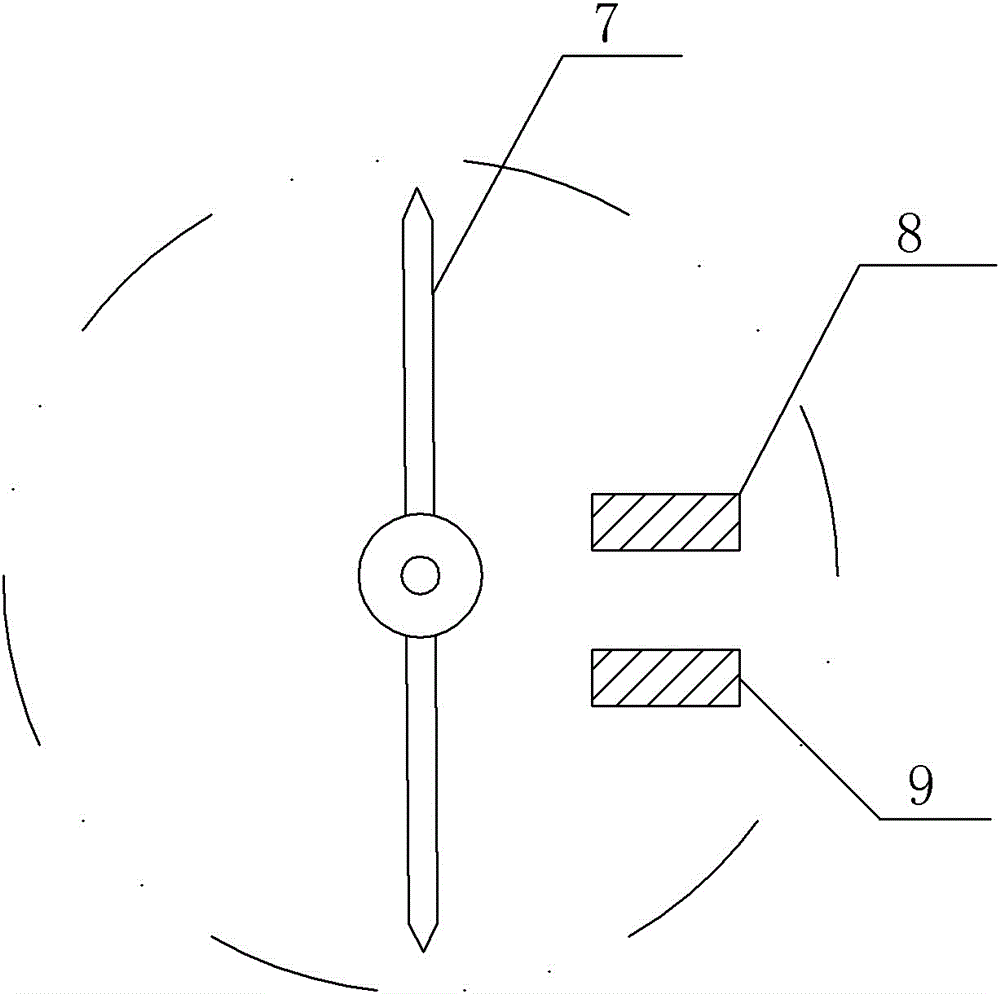

[0014] The reference signs in the drawings of the description include: body frame 1, partition plate 2, screen hole 3, transmission shaft 4, pulley 5, coupling 6, moving knife 7, upper knife seat 8, lower knife seat 9, crankshaft 10 , crank throw 11, hammer body 12, strip hole 13, rotating shaft 14, screw conveying sheet 15.

[0015] The embodiment is basically as attached figure 1 , figure 2 Shown: Edible fungus compost crushing equipment, including a body frame 1, a belt pulley 5 is installed outside the body frame 1, and a partition 2 is connected with bolts inside the body frame 1, and the partition 2 divides the body frame 1 from top to bottom sequentially. For the crushing chamber and the feeding chamber, the partition plate 2 has a number of sieve holes 3, through which the crushed materials in the crushing chamber can enter the feeding chamber.

[0016] The cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com