Sorting method and special production line of ABS, HIPS, PP, PE and GPPS plastic pieces or particles

A technology of ABS plastics and plastic fragments, applied in plastic recycling, chemical instruments and methods, wet separation, etc., can solve the problems of high cost and achieve the effects of low cost, low energy consumption and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

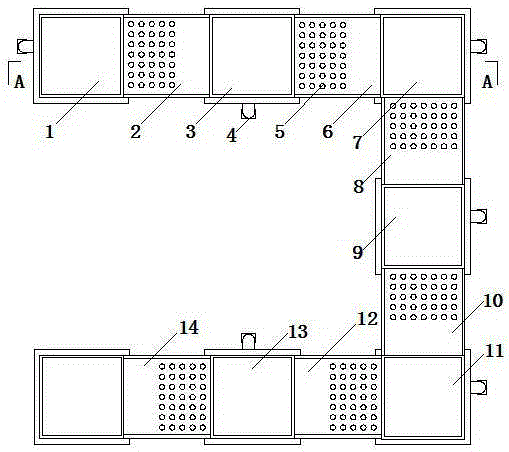

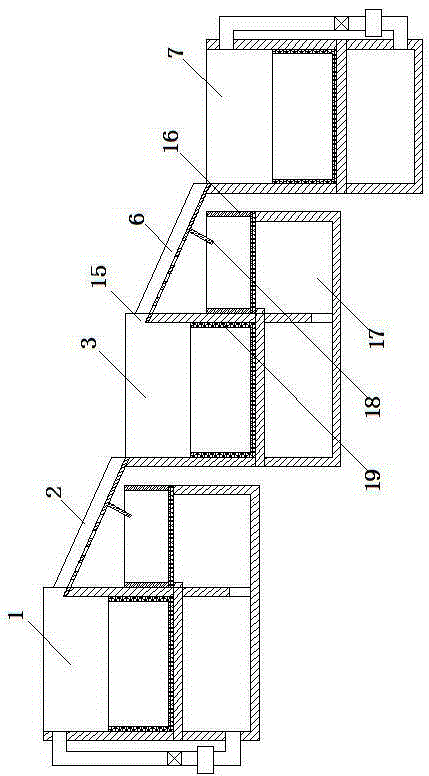

[0027] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

[0028] The sorting method of ABS, PP, HIPS, GPPS, PE plastic chips or particles of the present invention comprises the following steps:

[0029] a. Sorting out ABS plastic fragments or granules: put ABS, HIPS, PP, GPPS, PE plastic fragments or granule mixture in a container containing a sodium chloride solution with a concentration of 20%-21.5%, and the chloride in the container The preferred range of sodium solution concentration is 20%-21.5%, most preferably 20%. ABS plastic fragments or particles are deposited on the inner bottom of the container with 20%-21.5% sodium chloride solution, and HIPS, PP, GPPS, PE plastic fragments or particle mixture float on the surface layer of 20%-21.5% sodium chloride solution in the container , take out HIPS, GPPS, PP, PE plastic fragments or particle mixture, and sort out ABS plastic fragments or particles;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com