Continuous Preparation Process of Methyl Silicone Resin

A technology of methyl silicone resin and preparation process, applied in the field of continuous preparation technology of methyl silicone resin, can solve the problems of low production efficiency, poor mass transfer and heat transfer effect, large production energy consumption and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

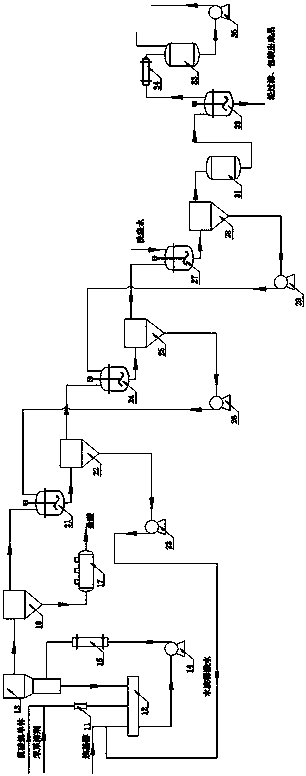

Image

Examples

Embodiment 1

[0033] A continuous preparation process of methyl silicone resin, carried out as follows:

[0034] Feed according to the following raw material ratio:

[0035] Methyltrichlorosilane: 100kg / h; Dimethyldichlorosilane: 22 kg / h; Xylene: 260kg / h.

[0036] Washing dilute acid water: 400 kg / h; ethanol: 20kg / h.

[0037] a. Hydrolysis

[0038] Methyltrichlorosilane, dimethyldichlorosilane, and xylene are mixed at a ratio of 5:1:13, and after being initially mixed in a static mixer 11, they enter the tubular hydrolysis reactor 12, where they are washed with dilute acid water and ethanol at a ratio of 20: The ratio of 1 enters the tubular hydrolysis reactor 12, and the washing dilute acid water is dilute hydrochloric acid with a mass concentration of 0.8% (the washing water after the first-level washing in the washing process of the previous kettle material can also be used). The hydrolysis temperature of the material is controlled at 15°C in the hydrolysis system. After the feeding i...

Embodiment 2

[0052] A continuous preparation process of methyl silicone resin, carried out as follows:

[0053] Feed according to the following raw material ratio:

[0054] Methyltrichlorosilane: 90kg / h; Dimethyldichlorosilane: 32 kg / h; Xylene: 250kg / h.

[0055] Washing dilute acid water: 400 kg / h; ethanol: 10kg / h.

[0056] a. Hydrolysis

[0057] Methyltrichlorosilane, dimethyldichlorosilane, and xylene are mixed at a ratio of 3:1:8, initially mixed in a static mixer 11, and then entered into a tubular hydrolysis reactor 12, and washed with dilute acid water and ethanol at a ratio of 40: The ratio of 1 enters the tubular hydrolysis reactor 12, and the dilute acid water for washing is dilute hydrochloric acid with a mass concentration of 0.9% (the washing water after the first-level washing in the washing process of the material in the previous kettle can also be used). The hydrolysis temperature of the material is controlled at 20°C in the hydrolysis system. After the feeding is complet...

Embodiment 3

[0071] A continuous preparation process of methyl silicone resin, carried out as follows:

[0072] Feed according to the following raw material ratio:

[0073] Methyltrichlorosilane: 85kg / h; Dimethyldichlorosilane: 35 kg / h; Xylene: 240kg / h.

[0074] Washing dilute acid water: 400 kg / h; ethanol: 8kg / h.

[0075] a. Hydrolysis

[0076] Methyltrichlorosilane, dimethyldichlorosilane, and xylene are mixed in a ratio of 2.5:1:7, and then enter the tubular hydrolysis reactor 12 after being initially mixed in a static mixer 11, and washed with dilute acid water and ethanol at a ratio of 50: The ratio of 1 enters the tubular hydrolysis reactor 12, and the dilute acid water for washing is dilute hydrochloric acid with a mass concentration of 0.9% (the washing water after the first-level washing in the washing process of the material in the previous kettle can also be used). The hydrolysis temperature of the material is controlled at 25°C in the hydrolysis system. After the feeding is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com