A kind of production method of superfine fiber synthetic leather with density gradient structure

A superfine fiber and density gradient technology, applied in the production field of superfine fiber synthetic leather, can solve the problems of low apparent density and influence of simulation degree, and achieve the effect of plump and soft hand feeling, improved quality and dense surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

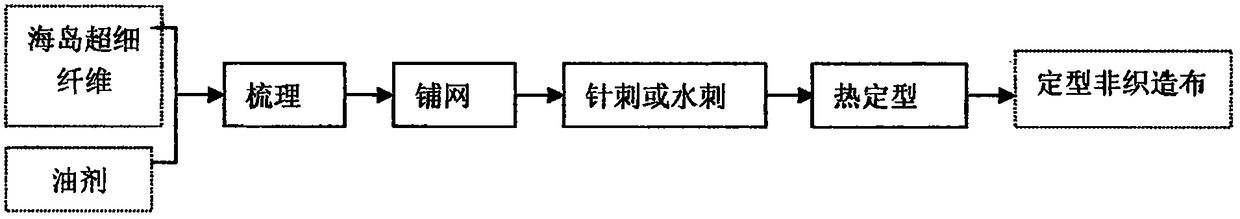

[0017] figure 1 It is a schematic diagram of step 1 in the present invention

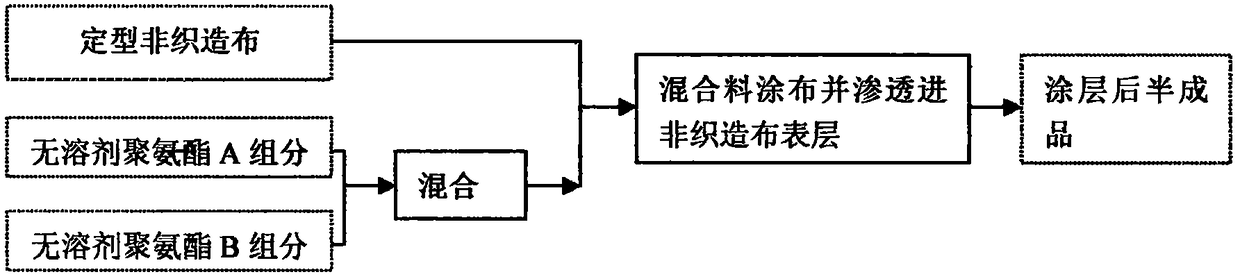

[0018] figure 2 It is a schematic diagram of step 2 in the present invention

[0019] image 3 It is a schematic diagram of step 3 in the present invention

[0020] Figure 4 It is a schematic diagram of step 4 in the present invention

[0021] Figure 5 It is a schematic diagram of step 5 in the present invention

[0022] Figure 6 It is a schematic diagram of step 6 in the present invention

[0023] A kind of production method of the superfine fiber synthetic leather with density gradient structure of the present invention comprises the steps:

[0024] 1. Sea-island superfine fiber processing: firstly, the sea component slices (such as polyethylene, water-soluble polyester, water-soluble cellulose and polypropylene slices) and the island component slices (such as polyamide slices, polyester slices) are two The raw materials are made into sea-island superfine fibers through the spinning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com