Hand-operated plumb bob device

A wire hammer and hand-cranked technology, applied in the field of hand-cranked wire hammer devices, can solve problems such as hidden safety hazards of operators working at heights, affecting construction progress, sliding form shutdown for testing, etc., to reduce the cumulative error of manual operation and improve construction efficiency , to avoid the effect of shutdown to be tested

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

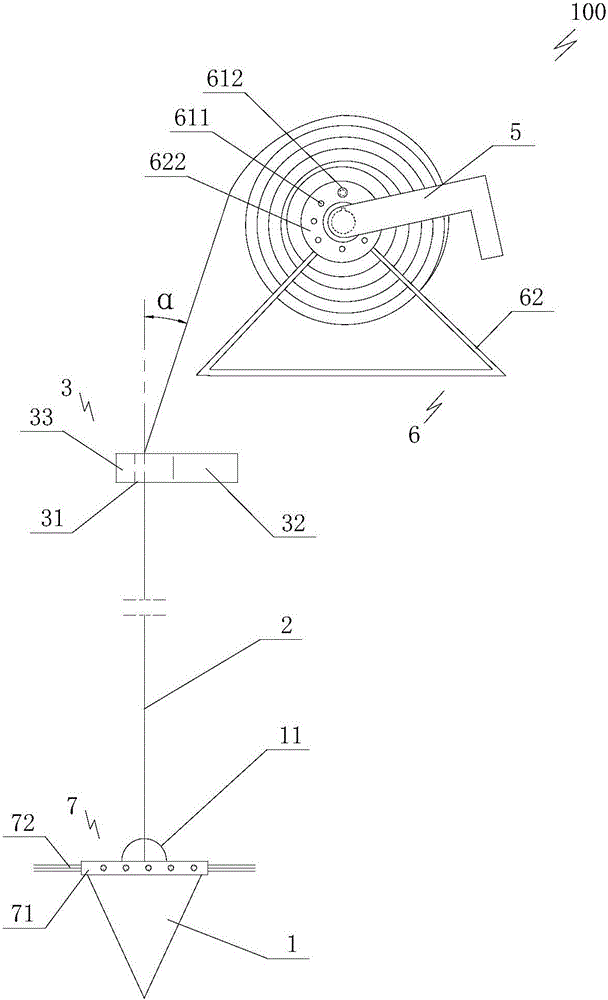

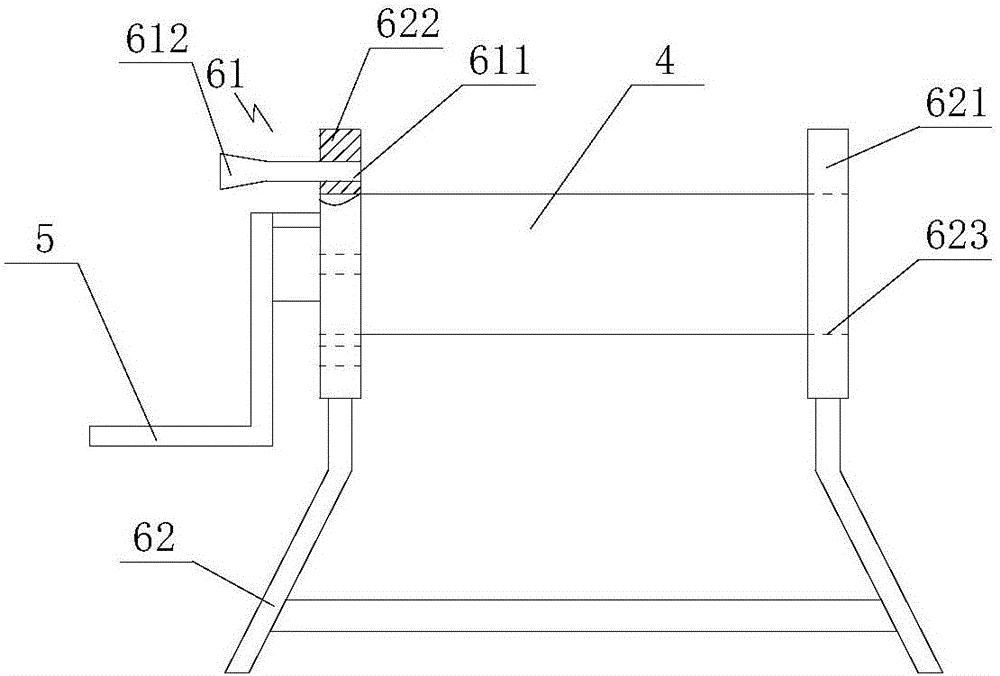

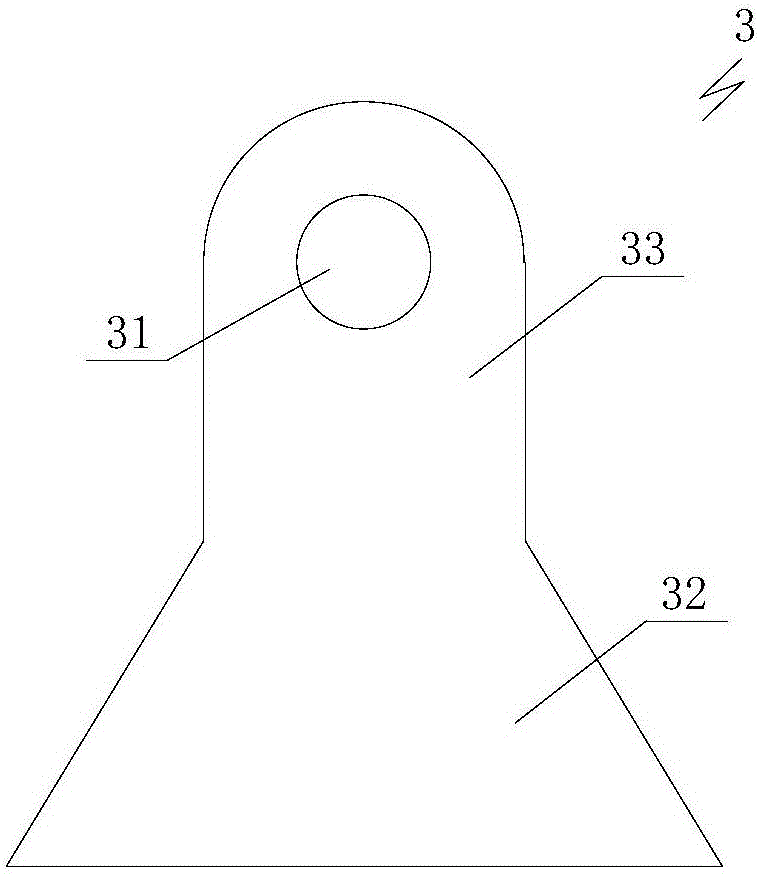

[0034] Such as figure 1 , figure 2 As shown, the hand-operated wire hammer device 100 provided by the present invention includes a wire hammer 1 on which a measuring disk 7 is arranged, and a test rope 2 is connected above the wire hammer 1 . In this embodiment, the top of the wire hammer 1 is provided with a There is a connecting part 11, which is fixedly connected to the test rope 2, and the hammer 1 is used to ensure the verticality of the test rope 2, generally not less than 5kg. In this embodiment, the test rope 2 adopts a φ2mm steel wire rope to meet the requirements of flexibility and wear resistance. At the same time, in order to realize the verticality observation of the highest pier, the length of the test rope shoul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com