Membrane structure and detection method for detecting reinforcement effect in vacuum preloading process

A detection method and vacuum membrane technology, which are applied in the fields of infrastructure engineering, soil protection, and on-site foundation soil survey, etc., can solve the problem of affecting the sealing performance of the vacuum system, destroying the vacuum preloading or vacuum combined stacking preloading and loading continuity. and other problems, to achieve the effect of ensuring the continuity of sealing and loading, ensuring continuity and stability, and good sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

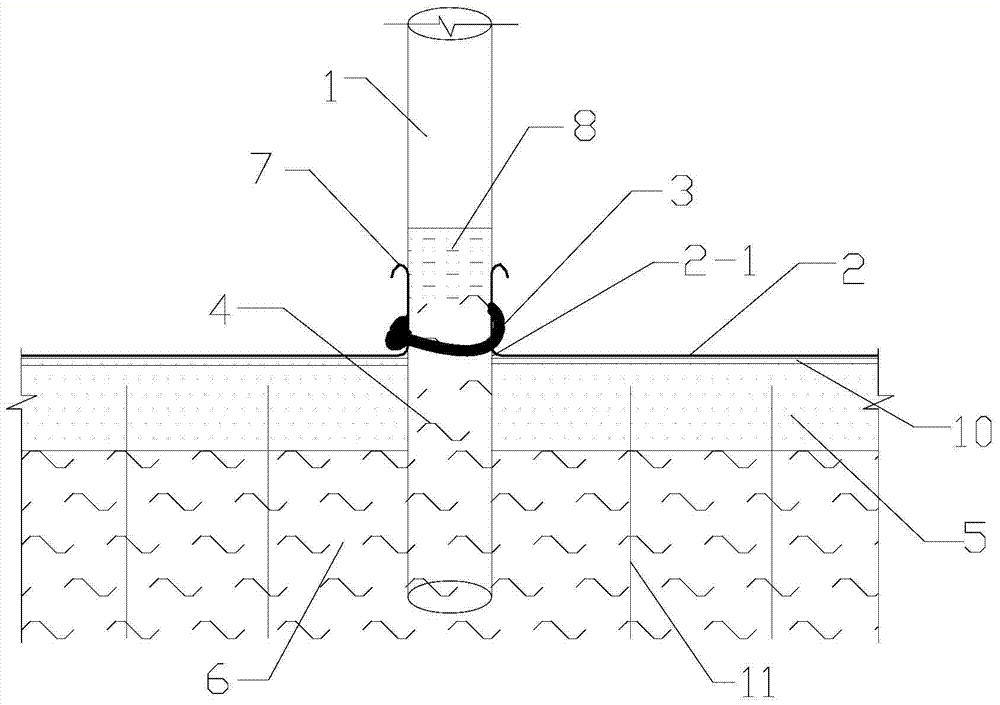

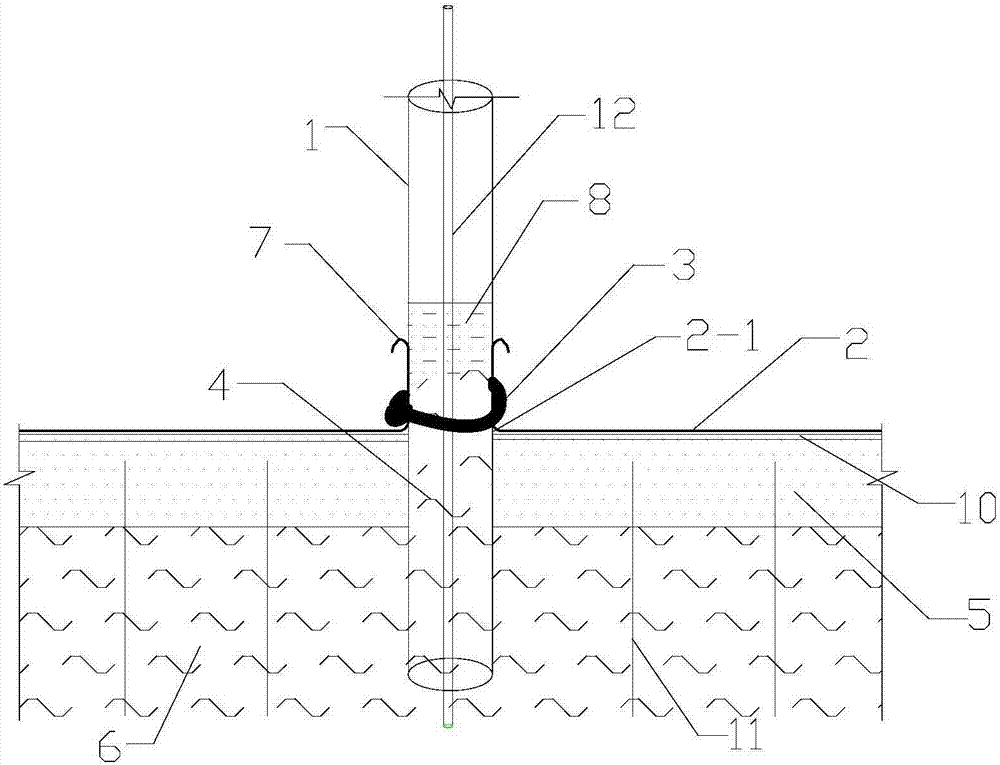

[0033] Embodiment one, such as figure 2 As shown, using the above membrane structure to detect the reinforcement effect during the vacuum preloading process, the specific steps are as follows:

[0034] ①. According to the length not less than 1500mm (the length of the outlet pipe embedded in the sludge is 500mm and the height above the drainage cushion is 500mm, the total length of the outlet pipe = 1000+ the thickness of the drainage cushion), the diameter of the pipe is 90mm ~ 150mm, and the membrane pipe is cut out 1;

[0035] ②. Pass the discharge pipe 1 through the drainage sand cushion 5, and bury it in the silt or muddy cohesive soil foundation to be reinforced. The depth of embedding is not less than 500mm. The discharge pipe 1 is about 500mm exposed from the cushion, and the nozzle is exposed Wrap it with geotextile to avoid scratching the vacuum membrane when laying the membrane;

[0036] ③. Clean the sand in the film outlet pipe in step ② and pour it into silt or...

Embodiment 2

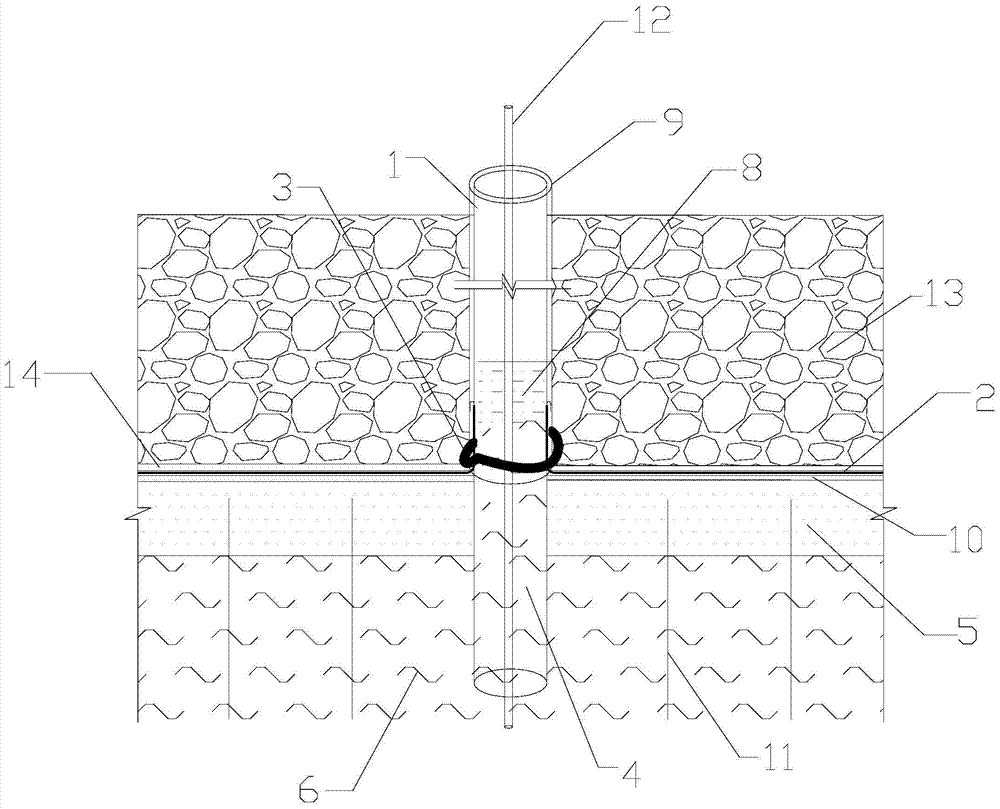

[0042] Embodiment two, such as image 3 As shown, using the film-out structure of the present invention to detect the reinforcement effect in the vacuum combined surcharge preloading process, the specific steps are as follows:

[0043] ①. The length of the first section of the film outlet pipe is not less than 1500mm (the length of the film outlet pipe buried in the mud is 500mm and the height above the drainage cushion is 500mm, the total length of the first section of the film outlet pipe = 1000 + the thickness of the drainage cushion, and the subsequent length is based on the stack The thickness of the loaded packing increases the corresponding length), the pipe diameter is 90mm~150mm, and the membrane pipe is cut out 1;

[0044] ②. Pass the membrane discharge pipe 1 through the drainage sand cushion 5, and embed it in the silt or silty cohesive soil foundation to be reinforced. The depth of embedding shall not be less than 500mm. The mouth is wrapped with geotextile to av...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com