Horizontal well staged fracturing oil production method through injection and production in same well

A technology of staged fracturing and injection and production in the same well, which is applied to wellbore/well components, production fluid, earthwork drilling and production, etc. It can solve the problems of difficult gas injection and high gas injection pressure, and achieve the reduction of development cost and over-flow Effect of area increase and enhanced oil recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039]A horizontal well staged fracturing method for injection and production in the same well, comprising:

[0040] 1) Staged fracturing of the wellbore of the horizontal well: multiple radial fracturing fractures perpendicular to the wellbore of the horizontal well are formed;

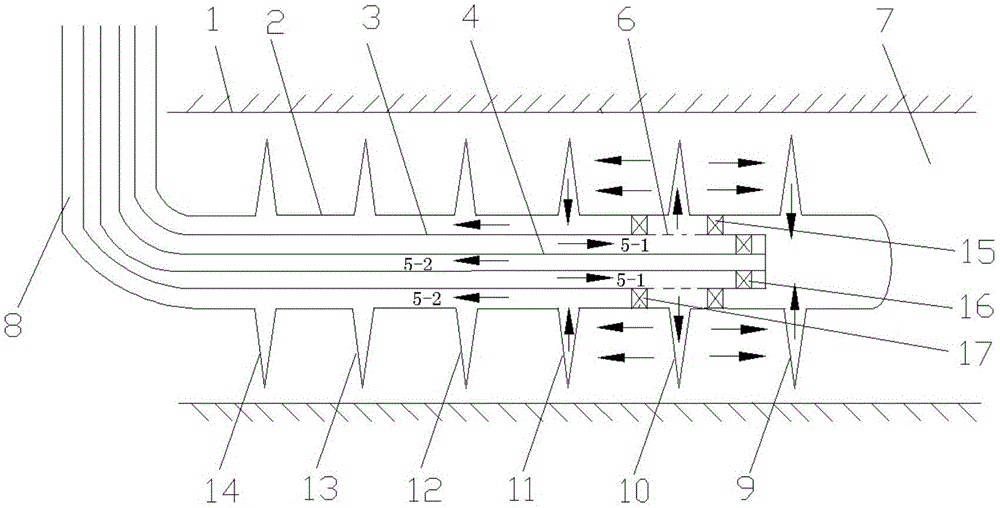

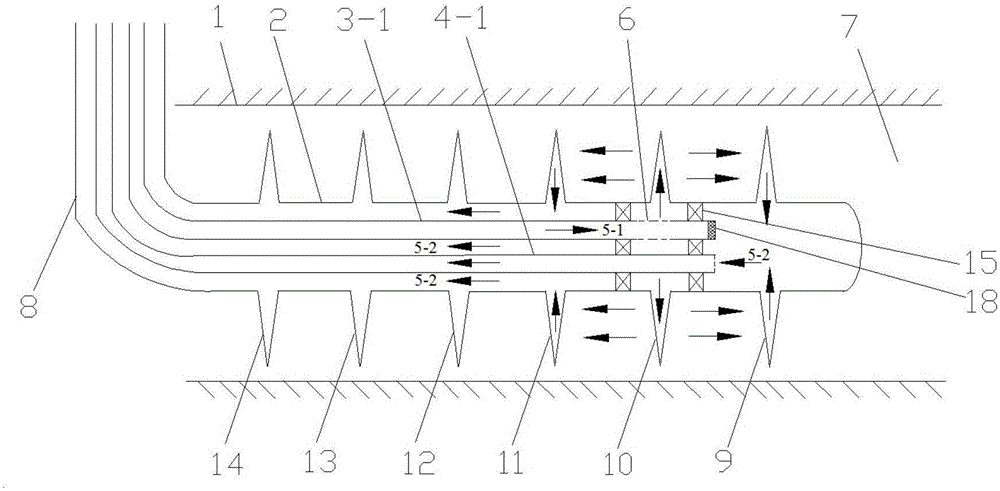

[0041] 2) Three adjacent fractures are selected in the fractures: the one located in the middle is the target injection fracture; the fractures located on both sides of the target injection fracture, and along the injection fluid injection direction are the production fracture I and the production fracture respectively. II; if figure 1 As shown, the fracturing fracture a9 is selected as the production fracture II, the fracturing fracture b10 is selected as the target injection fracture, and the fracturing fracture c11 is selected as the production fracture I;

[0042] 3) Install double-layer concentric oil pipes or parallel double oil pipes in the casing in the wellbore of the horizontal well: divid...

Embodiment 2

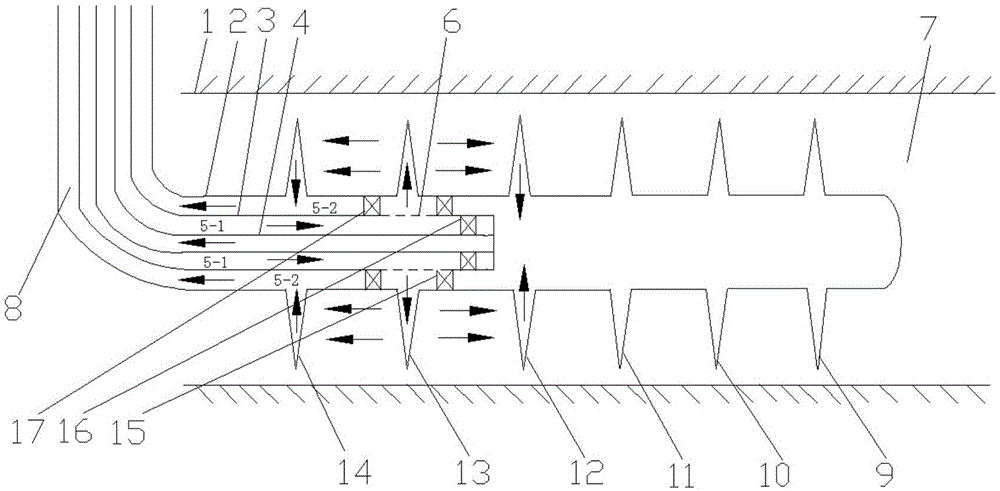

[0047] As described in Example 1, a horizontal well staged fracturing method for injecting and producing oil in the same well, the difference is that in the step 5), the fluid is continuously injected, and when the crude oil production drops below the economic production, the phase is reselected. Three adjacent fractures are used as a group of new injection-production fractures, that is, repeat steps 2)-step 5), until the crude oil controlled by all the fractures in the wellbore of the horizontal well is exploited. Such as figure 2 As shown, fracturing fracture d12 is selected as production fracture II, fracturing fracture e13 is selected as target injection fracture, and fracturing fracture f14 is selected as production fracture I.

Embodiment 3

[0049] As described in Example 1-2, a horizontal well staged fracturing method for injection and production in the same well, before the step 1), a low-permeability or tight oil reservoir suitable for horizontal wellbore staged fracturing is selected. Low-permeability reservoirs are preferred, the permeability is 15 mD, the oil layer thickness is 20 meters, and the oil layer does not contain edge and bottom water.

[0050] In the step 1), the horizontal well shaft is drilled along the minimum horizontal principal stress direction of the formation, and the horizontal well shaft is located in the middle and lower part of the oil layer. Here, the preferred horizontal well shaft length is 600 meters, and it is required that the part of the oil layer to be exploited does not contain edge and bottom water. Since edge and bottom water are likely to form water cones locally in the wellbore of horizontal wells or cause rapid water flooding, resulting in a large amount of water producti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com