Bearing with power generation function

A bearing and functional technology, applied in the field of bearings with power generation function, can solve the problems of complex structure, large space ratio, high cost, etc., and achieve the effect of small size, simple structure and simple bearing structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

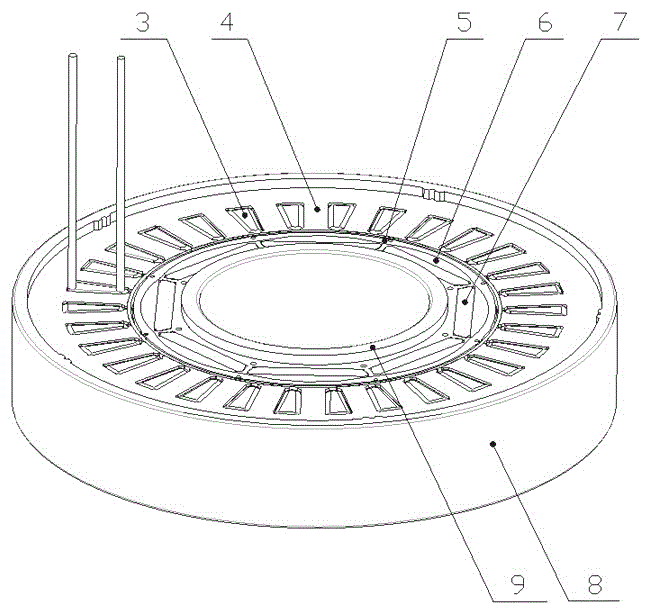

[0018] Such as Figure 5 As shown, the rotor punches made of 1J22 (Co50V2) material are laminated to a suitable size and height by a lamination process to form a ring-shaped rotor 6 . The annular rotor is uniformly provided with eight magnetic steel mounting holes along the circumferential direction of the annular rotor. Insert the magnetized steel 7 made of samarium-cobalt permanent magnet material with a height equal to the thickness of the annular rotor 6 into the corresponding magnetic steel installation hole on the annular rotor 6 and fasten it. The number of 7 magnetic steels is eight , when the magnetic steel is inserted into the magnetic steel installation hole of the annular rotor 6, it is installed on the opposite pole in the diameter direction. The so-called opposite pole installation means that the adjacent magnetic poles of two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com