Gas drive combined valve suitable for middle-high pressure difference sealing detection

A gas-driven combination valve and sealing detection technology, which is applied to valve details, multi-way valves, valve devices, etc., can solve the problems of limiting the service life of the air-tightness detection detection range, and achieve improved service life, pressure resistance, The effect of reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the patent of the present invention is further described.

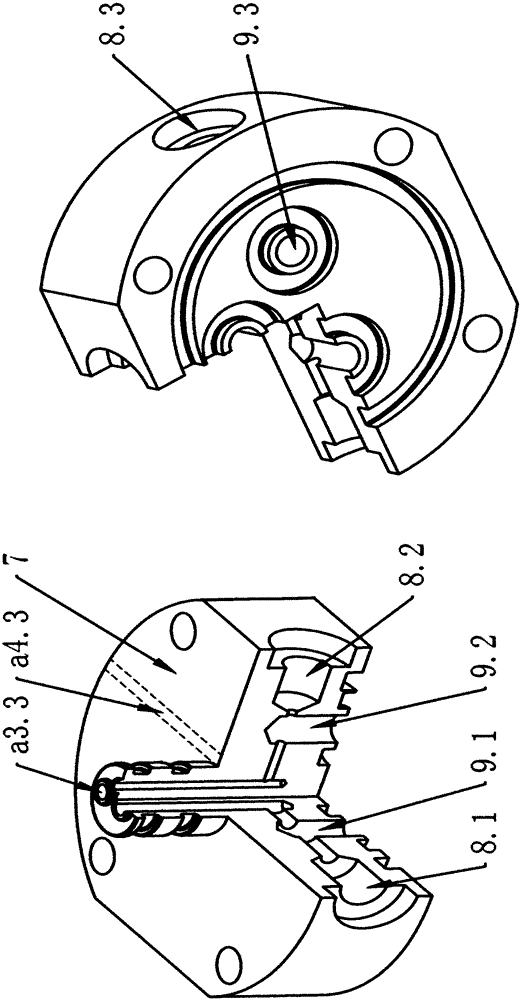

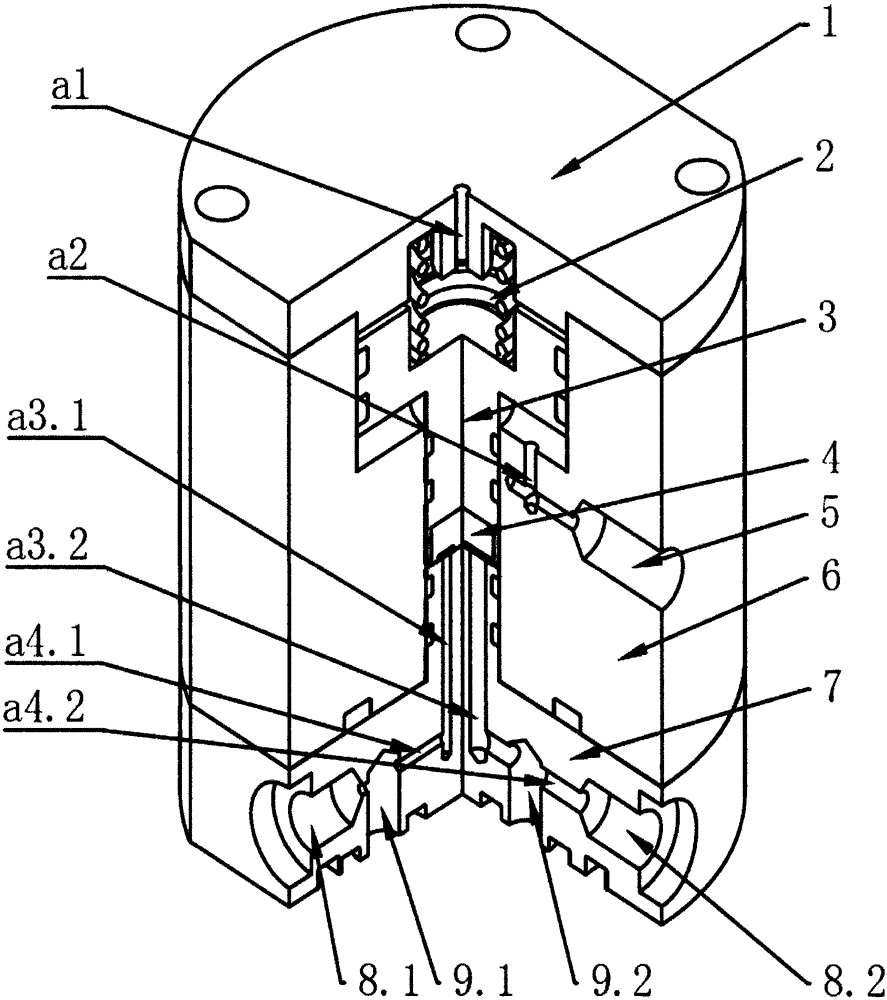

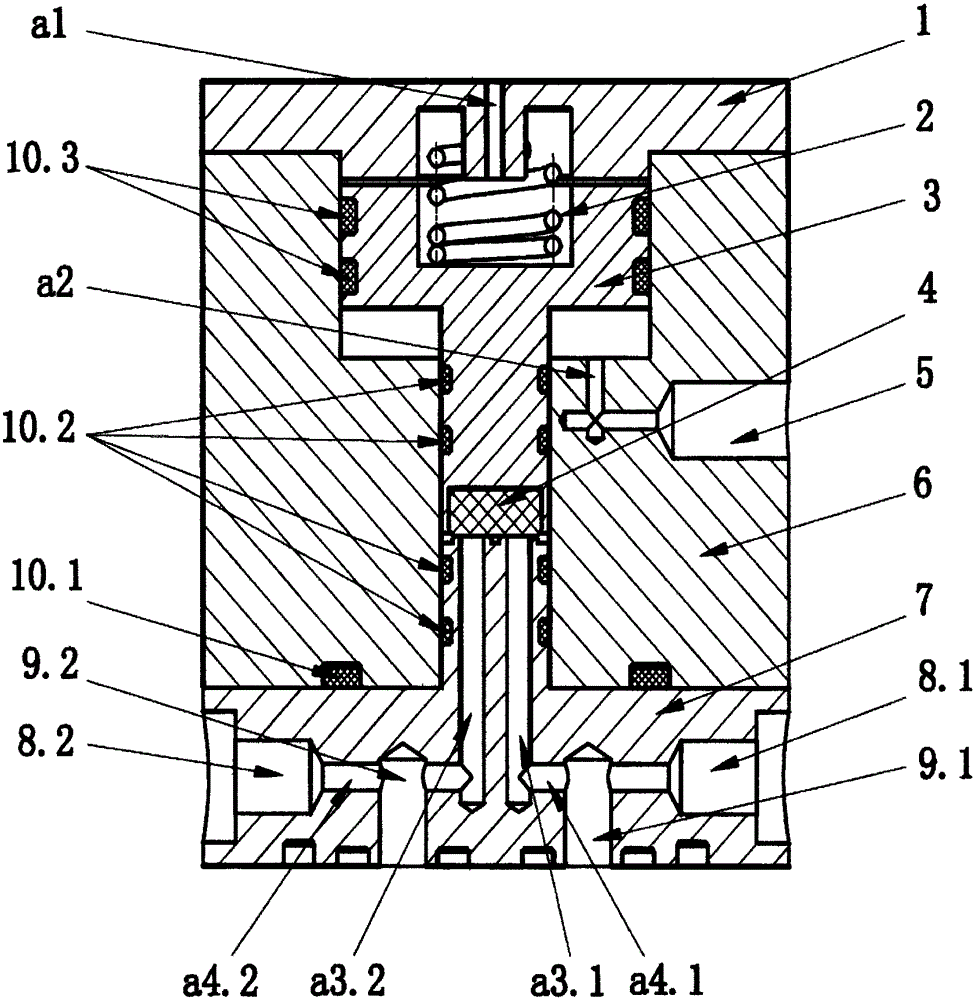

[0019] This preferred embodiment is figure 1 To such as image 3 It is a gas-driven combination valve suitable for medium and high pressure differential pressure seal detection, including valve seat 7, valve body 6, valve core 3, spring 2, valve cover 1, special plug 4 and air circuit system, etc. The whole valve is normally in a closed state, and the spring 2 is kept slightly stressed. When the valve body needs to be opened, the gas enters the combination valve through the air passage hole 5 on the side wall of the valve body, contacts the upper wall of the valve core 3, and the spring 2 is compressed by force, and the special plug 4 moves up with the valve core 3 and contacts with the valve seat 7. The small end faces are separated and contacted, and the gas flows into the cavity of the valve body along with the air intake path in the valve seat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com