A modulus-matched two-dimensional plane strain field test sensing element and its manufacturing method

A two-dimensional plane, sensing element technology, applied in the direction of electromagnetic measuring devices, electric/magnetic solid deformation measurement, etc., can solve the problems of limited use range, achieve high sensitivity, ensure test accuracy and strain test range, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

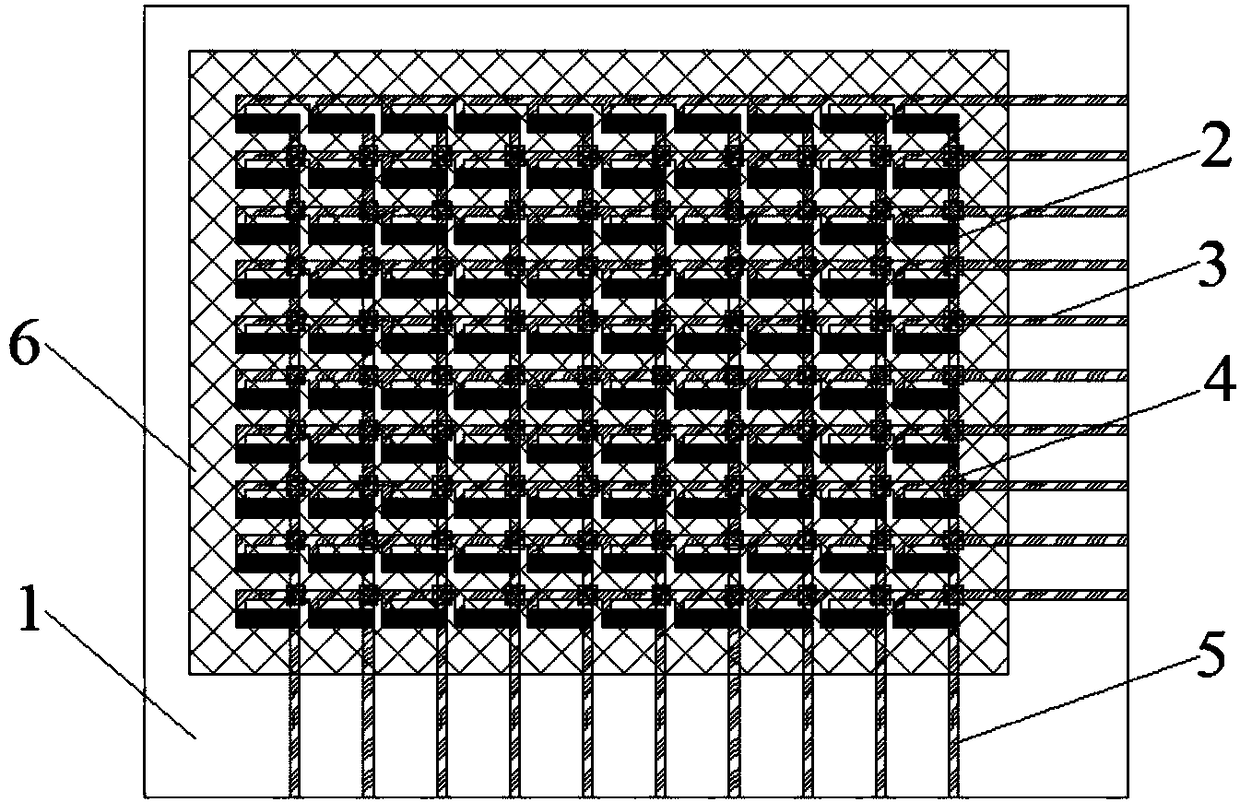

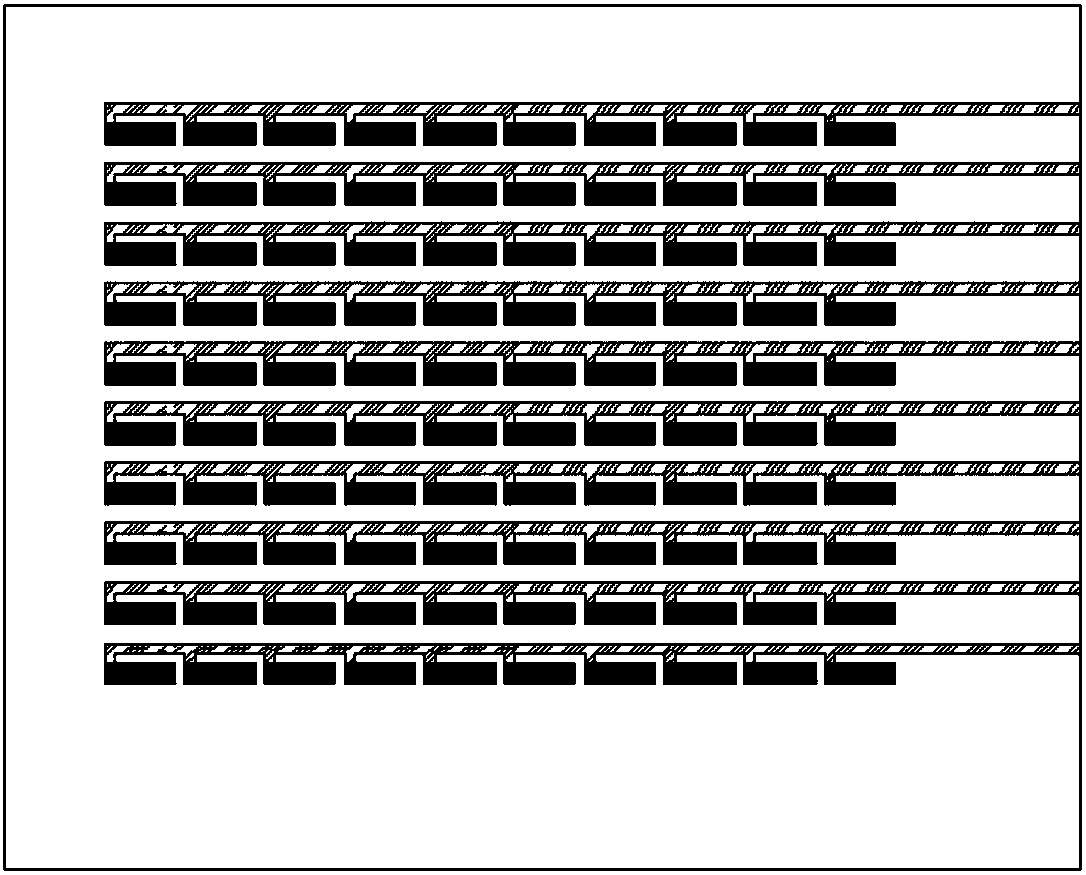

[0028] Embodiment 1: as figure 1 As shown, a modulus-matched two-dimensional plane strain field test sensing element of the present invention is composed of a thin plate 1 of the first layer, a sensitive element array 2 of the second layer, a lateral electrode 3, and an insulating thin film of the third layer. Layer 4, the longitudinal electrode 5 of the fourth layer and the insulating protective film 6 of the fifth layer. The object to be subjected to the strain test is a concrete structure, and an epoxy resin sheet with a smaller elastic modulus is selected as the sheet 1 of the first layer, and the thickness of the sheet 1 is selected as 0.3mm. The sensitive element display 2 on the second layer uses epoxy resin as a matrix and conductive carbon black as a filling material to prepare a conductive polymer composite material, and then prints it on the thin plate 1; before printing, the upper surface of the thin plate 1 is scrubbed clean with a solvent, Guaranteed printing ef...

Embodiment 2

[0030] Embodiment 2: as figure 1As shown, a modulus-matched two-dimensional plane strain field test sensing element of the present invention is composed of a thin plate 1 of the first layer, a sensitive element array 2 of the second layer, a lateral electrode 3, and an insulating thin film of the third layer. Layer 4, the longitudinal electrode 5 of the fourth layer and the insulating protective film 6 of the fifth layer. The object to be subjected to the strain test is a rock structure, and an epoxy resin sheet with a smaller elastic modulus is selected as the first layer of the sheet 1, and the thickness of the sheet 1 is selected to be 0.2mm. Sensitive element display 2 on the second layer, epoxy resin is used as the matrix, conductive carbon nanotubes are used as the filling material, and the conductive polymer composite material is prepared, and then printed on the thin plate 1; before printing, the upper surface of the thin plate 1 is wiped clean with a solvent , to ens...

Embodiment 3

[0032] Embodiment 3: as figure 1 As shown, a modulus-matched two-dimensional plane strain field test sensing element of the present invention is composed of a thin plate 1 of the first layer, a sensitive element array 2 of the second layer, a lateral electrode 3, and an insulating thin film of the third layer. Layer 4, the longitudinal electrode 5 of the fourth layer and the insulating protective film 6 of the fifth layer. The object of the strain test is the soil structure, and the silicon rubber sheet with a smaller elastic modulus is selected as the first layer of sheet 1, and the thickness of the sheet 1 is selected as 0.1mm. The sensitive element display 2 on the second layer uses silicone rubber as the matrix and conductive carbon black as the filling material to prepare a conductive polymer composite material, which is then printed on the thin plate 1; before printing, the upper surface of the thin plate 1 is scrubbed clean with a solvent to ensure D. The horizontal e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com