Stretchable, compressible and anti-freezing organic hydrogel electrolyte as well as preparation method and application thereof

A hydrogel and electrolyte technology, applied in compressible, antifreeze organic hydrogel electrolyte, and stretchable fields, can solve the problems of low-temperature performance compression performance degradation, etc., to achieve significant resistance changes, good low-temperature electrical properties, and good reversibility sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

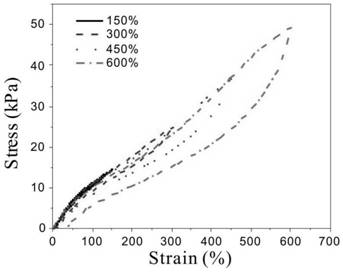

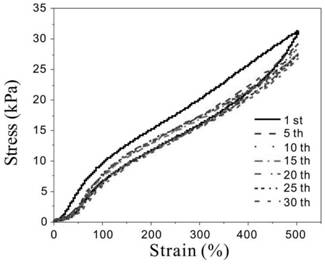

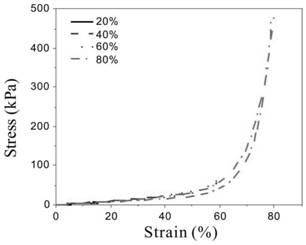

[0062] A Stretchable, Compressible, Freeze-resistant Organic Hydrogel Electrolyte S 1 A 4 And preparation method thereof, hydrogel electrolyte S 1 A 4 Including the following components by mass fraction:

[0063] Soy protein isolate 2.0%, SBMA 2.7%, AAm 10.9%, MBA 0.027%, lithium chloride 6.55%, ammonium persulfate 0.027%, the balance is DMSO and water, the mass ratio of DMSO and water is 3:7. S 1 A 4 The mechanical and electrical properties of the hydrogel are shown in Table 1.

[0064] Hydrogel Electrolyte S 1 A 4 The preparation method comprises the following steps:

[0065] a. Add 0.225g of soybean protein isolate, 2.55g of DMSO and 5.95g of water into a 20mL glass bottle, and place the glass bottle in a constant temperature water bath at 90°C for 2 hours;

[0066] b. Add SBMA and acrylamide to a glass bottle at a mass ratio of 1:4 (1.5 g in total), then add 0.003 g of MBA, 0.72 g of lithium chloride, and 0.0225 g of ammonium persulfate, and stir magnetically for ...

Embodiment 2

[0069] A Stretchable, Compressible, Freeze-resistant Organic Hydrogel Electrolyte S 1 A 1 And preparation method thereof, hydrogel electrolyte S 1 A 1 , including the following components by mass fraction:

[0070] Soy protein isolate 2.0%, SBMA 6.8%, AAm 6.8%, MBA 0.027%, lithium chloride 6.55%, ammonium persulfate 0.027%, the balance is DMSO and water, the mass ratio of DMSO and water is 3:7. S 1 A 1 The mechanical and electrical properties of the hydrogel are shown in Table 1.

[0071] Hydrogel Electrolyte S 1 A 1 The preparation method is the same as in Example 1, except that the mass ratio of SBMA to AAm is 1:1.

Embodiment 3

[0073] A Stretchable, Compressible, Freeze-resistant Organic Hydrogel Electrolyte S 1 A 8 And preparation method thereof, hydrogel electrolyte S 1 A 8 , including the following components by mass fraction:

[0074] Soy protein isolate 2.0%, SBMA 1.52%, AAm 12.1%, MBA 0.027%, lithium chloride 6.55%, ammonium persulfate 0.027%, the balance is DMSO and water, the mass ratio of DMSO and water is 3:7. S 1 A 8 The mechanical and electrical properties of the hydrogel are shown in Table 1.

[0075] Hydrogel Electrolyte S 1 A 8 The preparation method is the same as in Example 1, except that the mass ratio of SBMA to AAm is 1:8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| toughness | aaaaa | aaaaa |

| tensile stress | aaaaa | aaaaa |

| compressive stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com