Conductive organic silicon elastomer based on MXene as well as preparation method and application of conductive organic silicon elastomer

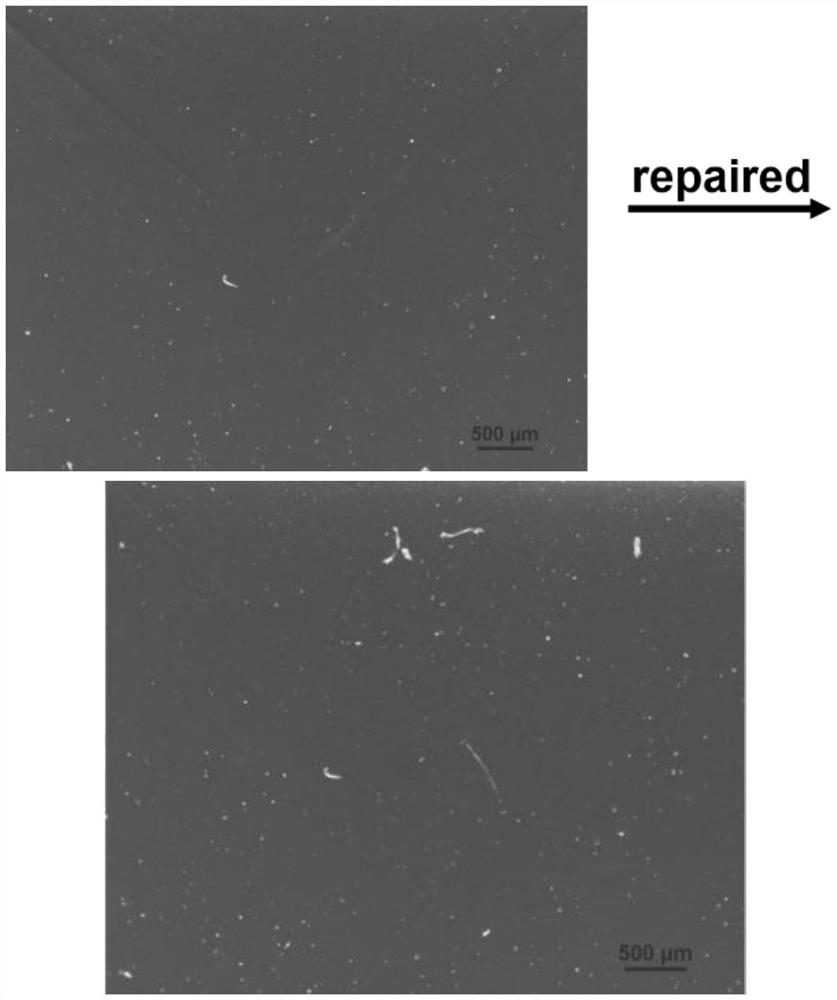

A technology of elastomer and silicone, which is applied in the field of conductive silicone elastomer and its preparation, can solve the problems of unstable material conductivity, lack of self-healing performance, and inability to continue to apply, so as to achieve environmental protection in the preparation process and high efficiency at room temperature. The effect of healing ability and excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

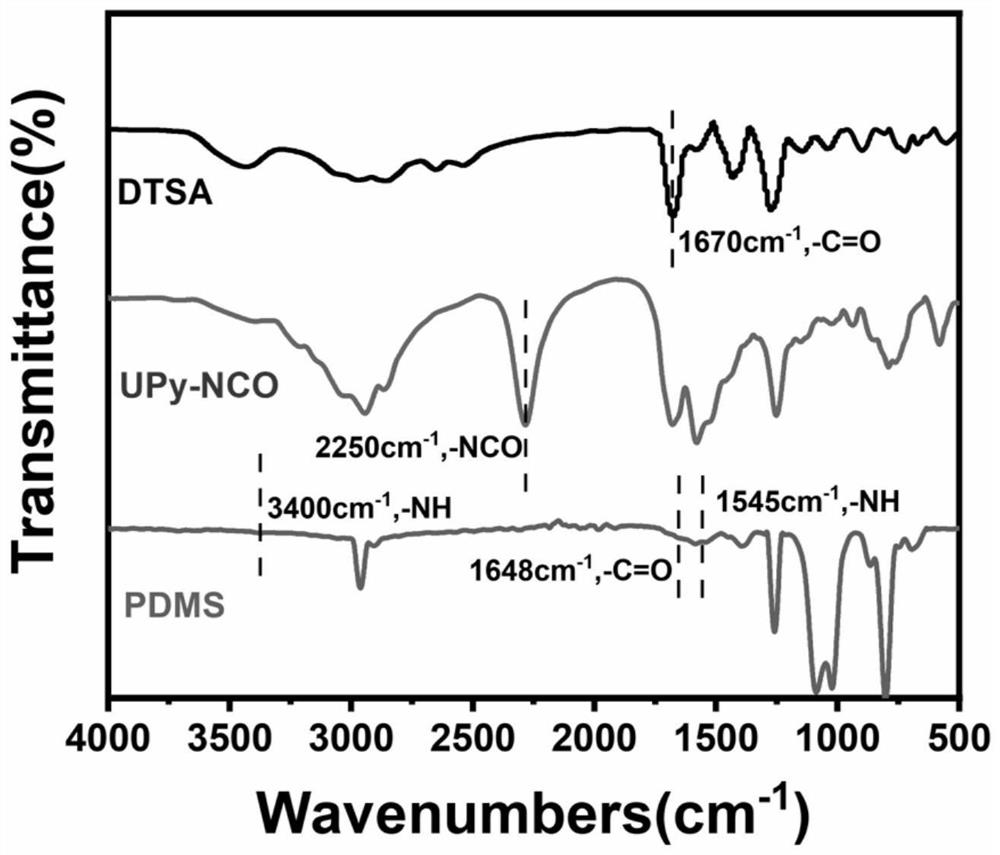

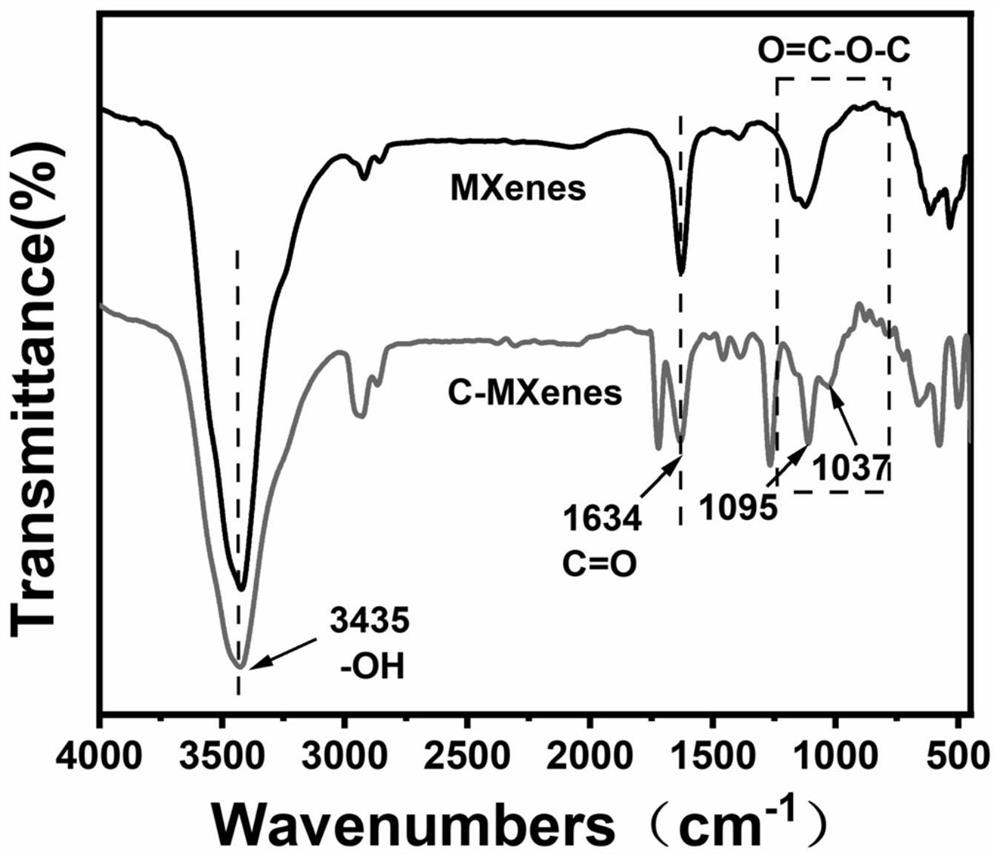

[0060] According to the present invention, the preparation method of the conductive silicone elastomer based on MXene, a kind of preferred embodiment, comprises steps as follows:

[0061] Disperse UPy-NCO and amino functionalized polysiloxane derivative A in dichloromethane, react at 50°C-70°C for 12-24h, after the reaction is completed, add carboxylic acids containing disulfide bonds to derivate Compound B was reacted at 50°C-70°C for 6-12h to obtain polysiloxane derivative C containing multiple reversible bonds; disperse MXenesE and carboxyl-containing L-citrulline D in deionized water, React for 12 to 24 hours, wash 5 times with a high-speed centrifuge to obtain the modified MXenesF; ultrasonically disperse the modified MXenesF into the organosilicon polymer network of polysiloxane derivative C containing multiple reversible bonds, stir and ultrasonically The reaction was shaken for 1 hour, and then solidified to form a film, and the MXene-based conductive silicone elastome...

Embodiment 1

[0077] 0.16 g of UPy-NCO and 10 g of branched polydimethylaminosiloxane (Mn: 2000) were mixed in a three-necked flask. The temperature was raised to 70°C, and the reaction time was 16h. 0.84g of 2,2'-dithiodibenzoic acid was added to the reactant, and the reaction continued for 4h. After the reaction is completed, the product is poured into a polytetrafluoroethylene mold and placed in a vacuum drying oven at 40°C until constant weight to obtain polysiloxane containing disulfide bonds and multiple hydrogen bonds. 1gMXenes (multilayer Ti 3 C 2 ) was dispersed in 15 ml of deionized solution to obtain a suspension. 0.3g L-citrulline, multilayer Ti 3 C 2 The suspension was added to a 50ml three-necked flask equipped with a reflux device and a stirrer and mixed uniformly at 100°C. After 12 hours of reaction, the modified multilayer Ti 3 C 2 . 10g of polysiloxane containing disulfide bonds and multiple hydrogen bonds was mixed with 1g of modified multilayer Ti 3 C 2 Ultraso...

Embodiment 2

[0082] The procedure described in Example 1 was repeated, except that 0.84 g of 2,2'-dithiodibenzoic acid was replaced by 0.46 g of 2,2'-dithiodipropionic acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com