Antibacterial organic silicon elastomer as well as preparation method and application thereof

An elastomer and silicone technology, which is applied in the field of preparation of antibacterial silicone elastomers, can solve the problems of excellent electrical conductivity and inability to have both, and achieve the effects of excellent electrical conductivity, universality and simple operation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

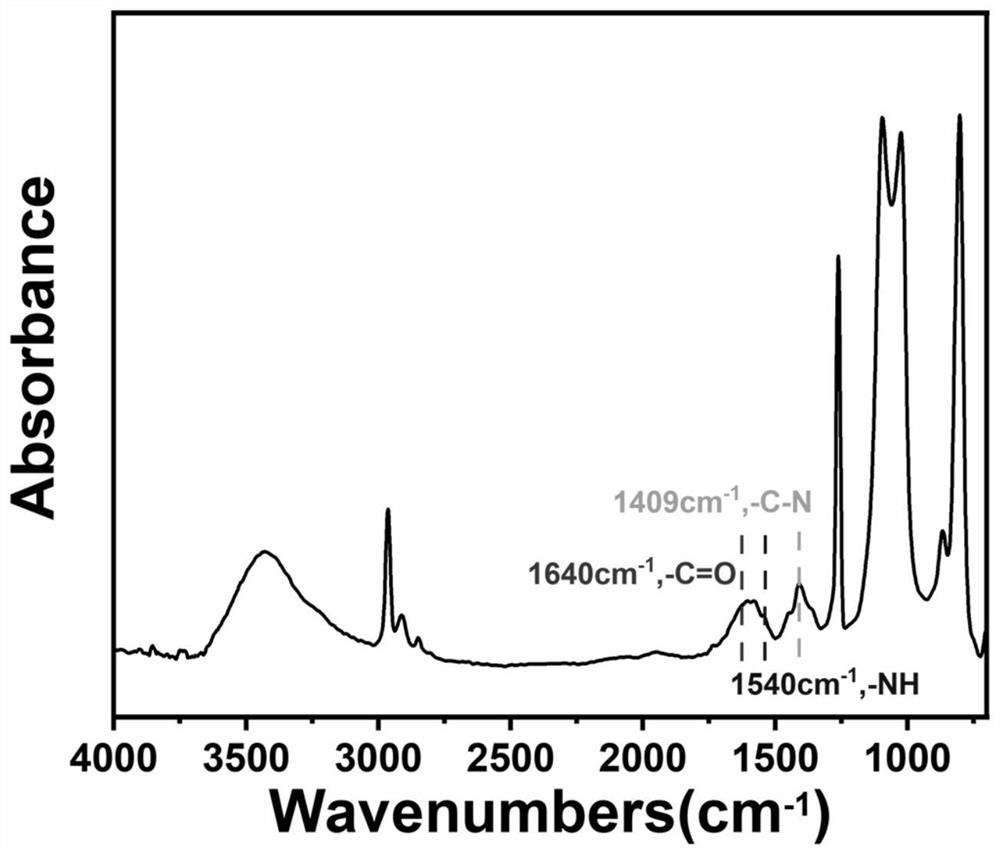

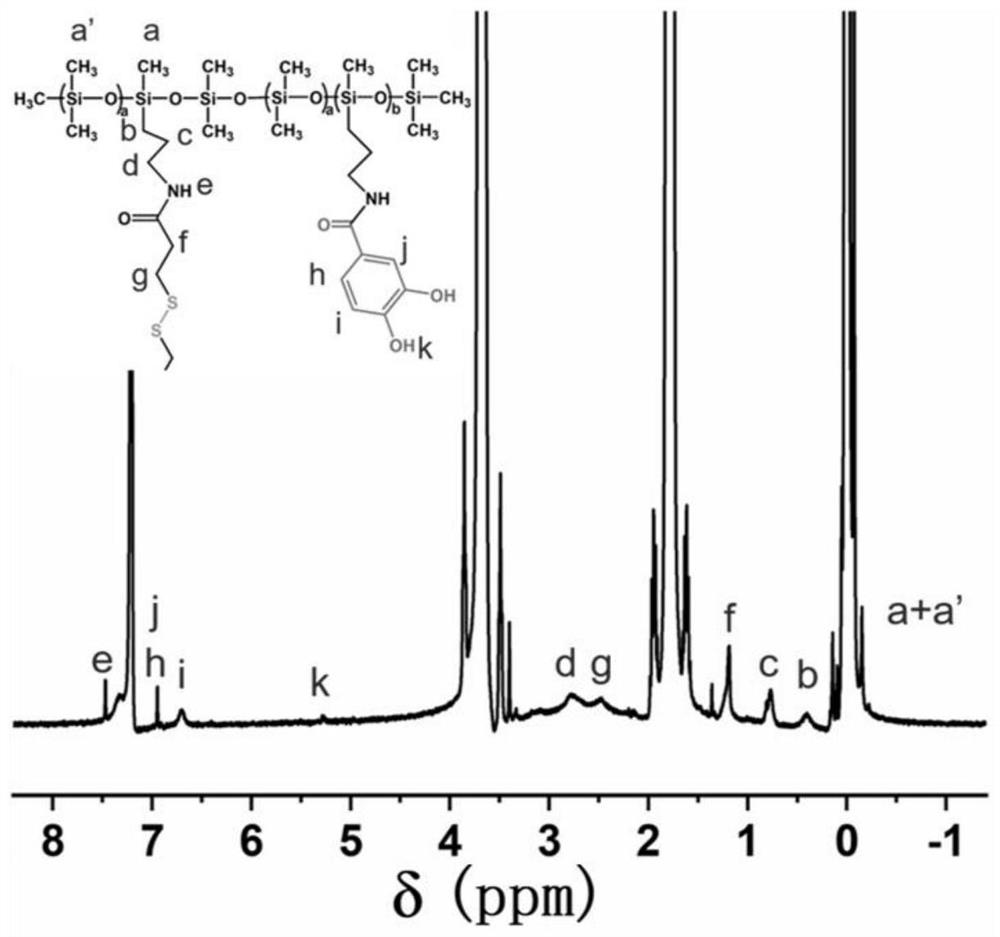

[0065] The preparation method of the antibacterial silicone elastomer of the present invention, a preferred embodiment, comprises: containing amino polysiloxane derivative A and monomer derivative B containing catechol residue and containing disulfide bond Carboxylic acid derivative C is dissolved in tetrahydrofuran and reacted at 50°C to 70°C for 12 to 24 hours to obtain polysiloxane derivative D containing amide bonds, disulfide bonds and catechol residues. React the polysiloxane derivative D containing amide bonds, disulfide bonds and catechol residues with zinc salt in tetrahydrofuran at 50°C to 70°C for 2 to 6 hours to obtain amide bonds and disulfide bonds Polysiloxane derivative E with metal coordination bond. Ultrasonic disperse the silver nanoparticles F into the organic silicon polymer network, stir and ultrasonically vibrate for 1 hour, solidify and form a film, and obtain the organic silicon composite material.

[0066] In order to achieve the long-term use stabil...

Embodiment 1

[0079] Dissolve 20g of branched polydimethylaminosiloxane (Mn: 2000), 0.8g of 3,4-dihydroxybenzoic acid (98% purity) and 0.72g of 3,3'-dithiodipropionic acid in an appropriate amount In tetrahydrofuran, mix uniformly at 60° C., and react for 12 hours to obtain polysiloxane containing disulfide bonds, amide bonds and catechol residues. Then 0.36g of zinc chloride was dissolved in tetrahydrofuran and added to the prepolymer solution, and the reaction was continued for 2h to obtain polysiloxane derivatives containing amide bonds, disulfide bonds and catechol residues. 10 g of polysiloxane containing amide bonds, disulfide bonds and catechol residues and 1 g of silver nanoparticles were stirred at room temperature and ultrasonicated for 1 hour to obtain an antibacterial silicone elastomer.

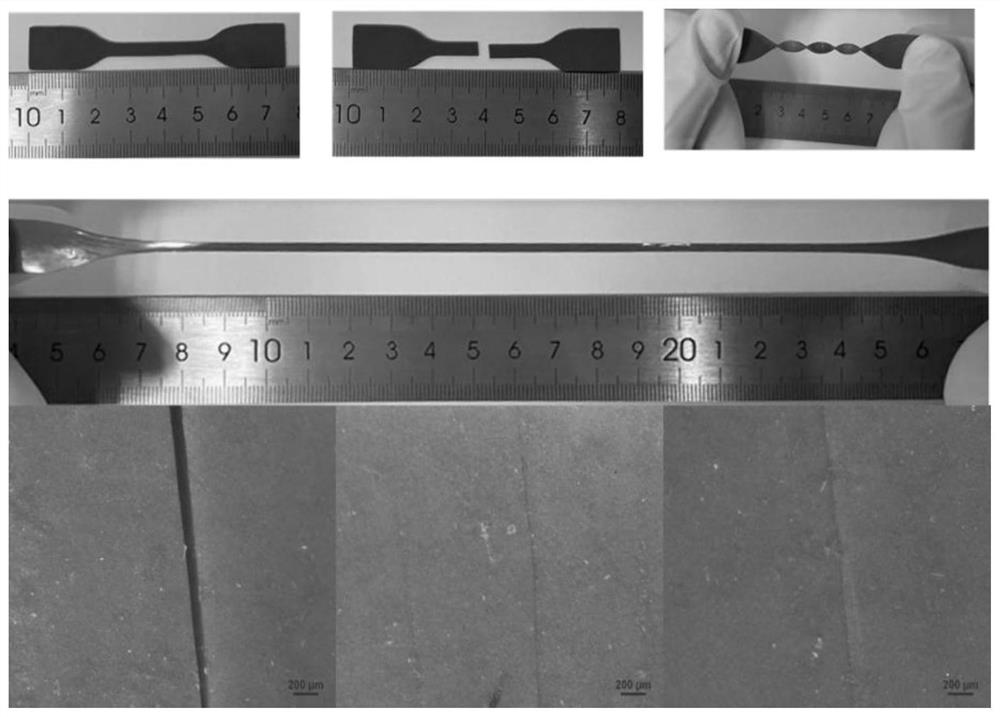

[0080] Cut the antibacterial silicone elastomer into a dumbbell shape (length×width×thickness: 50×4×1mm 3 ), the sample was broken at room temperature by an Instron3343 electronic universal t...

Embodiment 2

[0084] The procedure described in Example 1 was repeated, except that 0.8 g of 3,4-dihydroxybenzoic acid was replaced by 0.88 g of 3,4-dihydroxyphenylacetic acid (purity: 98%).

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com