A flexible and repairable conductive silicone composite material and its preparation method and strain sensor application

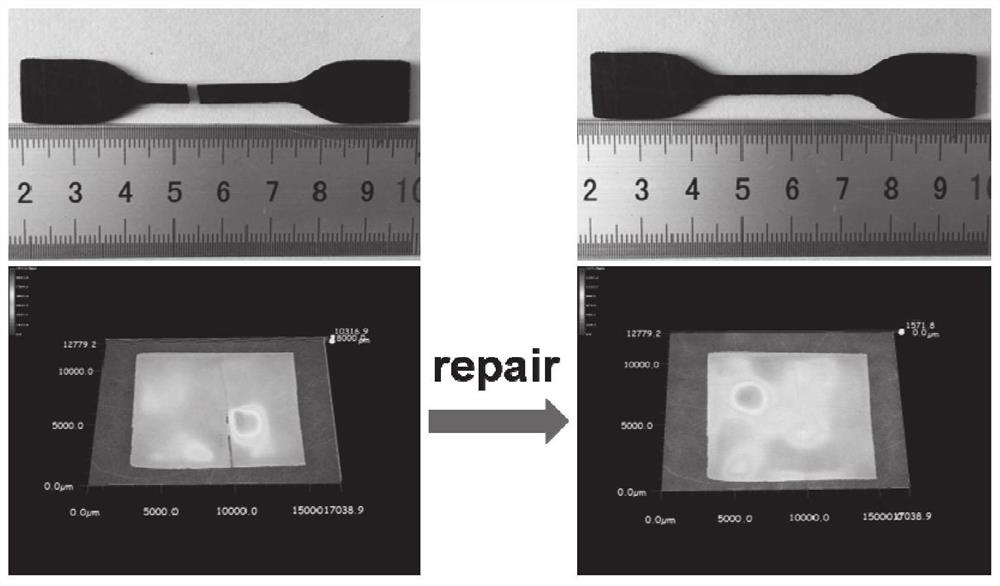

A composite material and silicone technology, which is applied in the field of flexible and repairable conductive silicone composite materials and its preparation, to achieve the effects of high-efficiency room temperature self-healing ability, sensitive sensing ability, and simple operation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

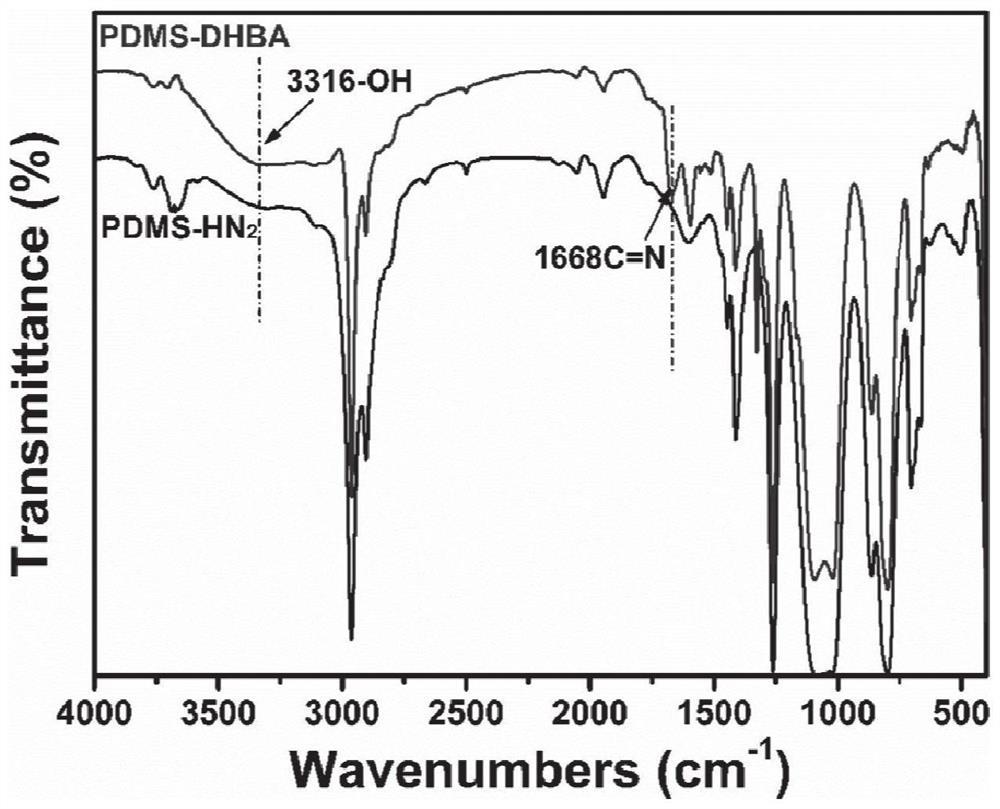

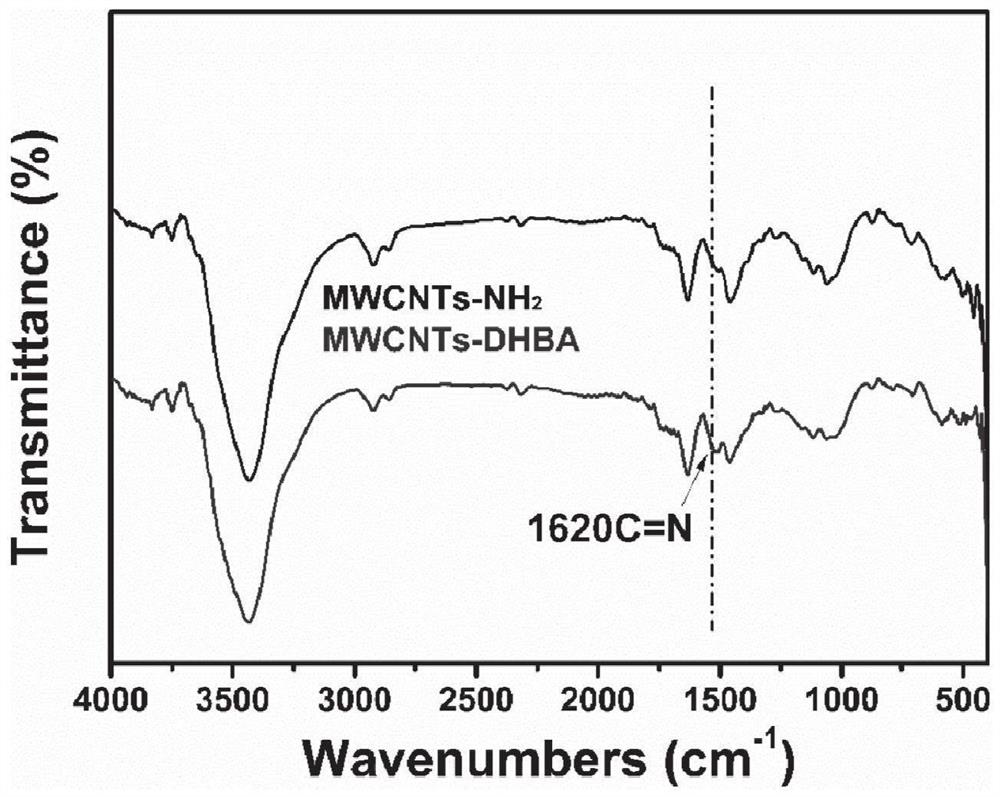

[0066] Dissolve 10g of branched polydimethylaminosiloxane (Mn: 2000), 1.38g of 3,4-dihydroxybenzaldehyde (purity: 98%) in an appropriate amount of tetrahydrofuran (the monomer concentration is kept at about 0.1g / ml) , mixed uniformly at 60°C, and reacted for 12 hours to obtain polysiloxane containing imine bonds and catechol residues. Disperse 1g of amino-modified multi-walled carbon nanotubes (amino group: 0.45wt%) and 0.04g of 3,4-dihydroxybenzaldehyde (purity: 98%) in an appropriate amount of tetrahydrofuran, mix uniformly at 60°C, and react for 12 hours. Multi-walled carbon nanotubes containing imine bonds and catechol residues were obtained. 10g of polysiloxane containing imine bonds and catechol residues and 1g of multi-walled carbon nanotubes containing imine bonds and catechol residues were ultrasonically dispersed at room temperature, and 1.4g of zinc chloride was added to make Metal ion: ligand is equal to 1:2. Continue to stir at room temperature and sonicate for ...

Embodiment 2

[0071] The procedure described in Example 1 was repeated, except that 1.38 g of 3,4-dihydroxybenzaldehyde was replaced by 1.52 g of 3,4-dihydroxyphenylacetaldehyde (purity: 98%).

Embodiment 3

[0073] Repeat the steps described in Example 1, except that 10 g of branched polydimethylaminosiloxane (Mn: 2000) is replaced by 10 g of branched polydimethylaminosiloxane (Mn: 5000).

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com