Fiber grating demodulator calibration transfer member and calibration method

A fiber grating and demodulator technology, applied in the direction of instruments, etc., can solve the problems of fiber grating external temperature change sensitivity, poor environmental adaptability, and few calibration wavelength points, etc., to achieve good temperature stability, reduce requirements, and meet calibration requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the drawings and specific implementations:

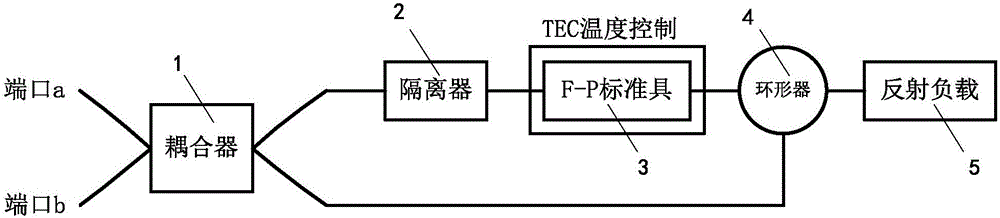

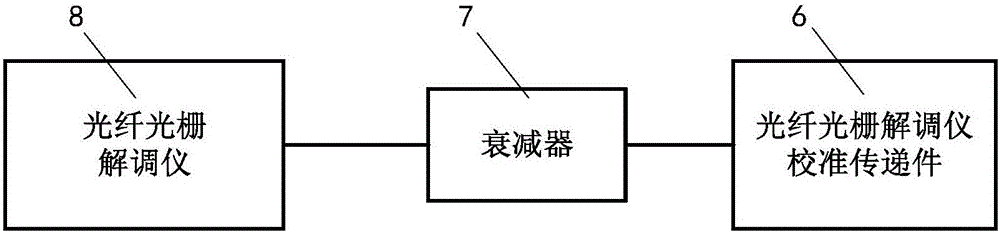

[0025] Combine figure 1 As shown, the calibration transfer part of the fiber grating demodulator includes a 2×2 coupler 1, an isolator 2, an F-P etalon 3, a circulator 4 with three ports, and a reflection load 5. among them,

[0026] One end of the coupler 1 is connected to one end of the F-P etalon 3 through the isolator 2; the other end of the F-P etalon 3 is connected to one port of the circulator 4.

[0027] The other two ports of the circulator 4 are connected to the reflective load 5 and the other end of the coupler 1 respectively.

[0028] The FP etalon 3 can generate a series of equally spaced wavelength points within the working wavelength range of the fiber grating demodulator to ensure that the calibration data has high reliability, and it has wavelength marking points, which can be determined according to the wavelength marking points The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com