Demagnetizing circuit and method for removing residual magnetism of electromagnetic current transformer on line

A current transformer, electromagnetic technology, applied in inductors, circuits, transformers, etc., can solve the problems of reduced magnetic circuit efficiency, reduced measurement accuracy, increased magnetic flux leakage, etc., to achieve fast demagnetization speed, improve accuracy, and improve The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing of description, the present invention will be further described.

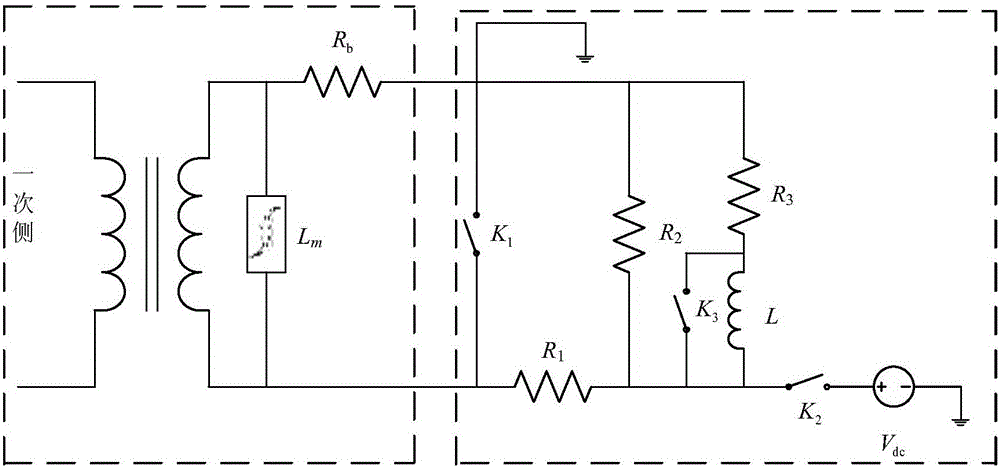

[0022] as attached figure 1 As shown, in the demagnetization circuit used to eliminate the residual magnetism of the electromagnetic current transformer online, the excitation inductance L of the current transformer m Parallel to the secondary side, grounded winding equivalent resistance R b Located at one end of the secondary side; characterized in that the demagnetization circuit includes a third resistor R 3 A series structure composed of inductance L, in which both ends of inductance L are also connected in parallel with the third switch K 3 ; The series structure and the second resistor R 2 and the first switch K 1 are connected in parallel to both ends of the secondary side of the current transformer; the third resistor R 3 The outer end of the inductor L is grounded, and the outer end of the inductor L passes through the second switch K 2 connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com