Current-adjustable multipolar permanent magnetic electric welding machine set

An electric welding unit and current regulation technology are applied to arc welding equipment, conversion equipment that can be converted to direct current without intermediate conversion, and electrical components. Meet welding needs and adapt to a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with specific embodiments.

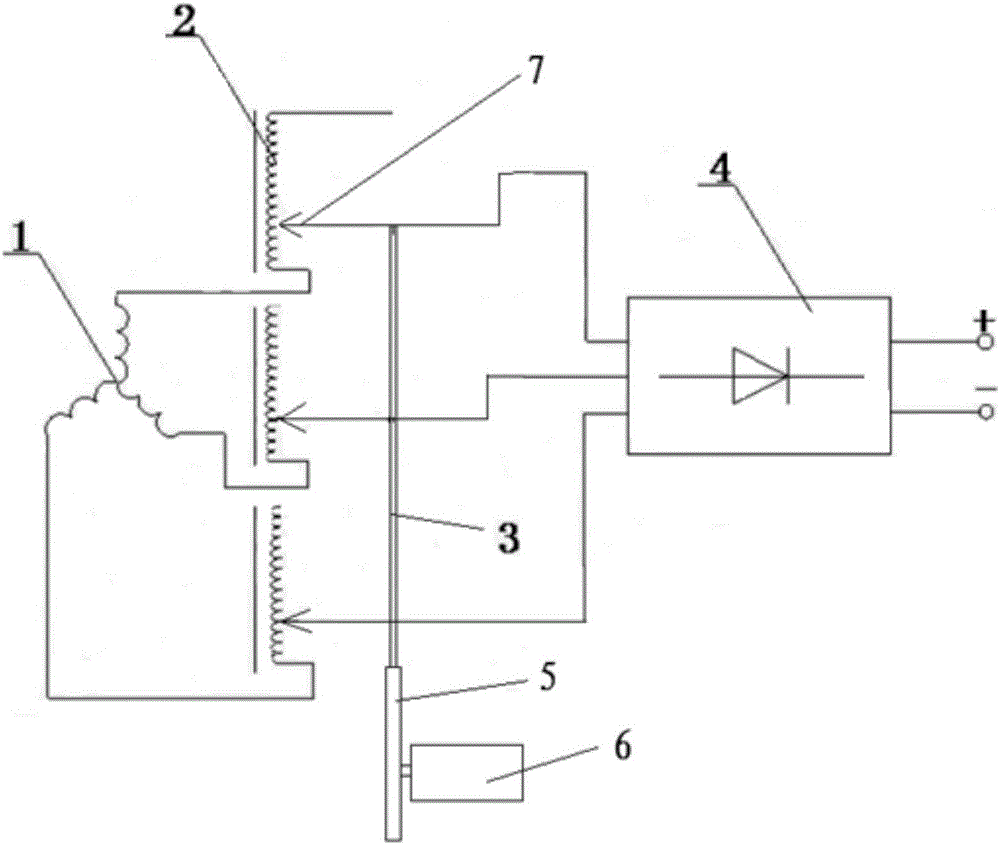

[0015] Such as figure 1 As shown, the multi-pole permanent magnet electric welding unit with adjustable current includes a generator and a rectifier 4, the generator includes a stator winding 1, and the three winding terminals of the stator winding 1 are respectively connected to the input terminals of the three reactors 2, and the reactance The device 2 is provided with a sliding contact 7 for adjusting the reactance value, and the three sliding contacts 7 are respectively connected with the three input terminals of the rectifier 4, and the output terminals of the rectifier 4 output current for welding; The front end of the head 7 is overlapped with the reactor 2, and the rear end of the sliding contact 7 is installed on a vertically arranged support rod 3. The lower end of the support rod 3 is connected with a rack 5, and the rack 5 is connected to the output sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com