corn stubble harvester

A harvester, stubble technology, applied in the field of agricultural machinery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

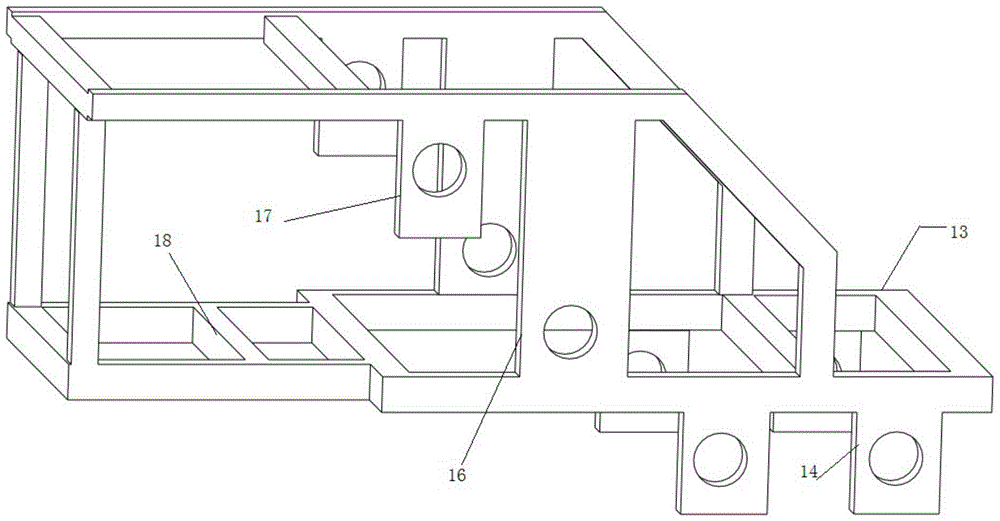

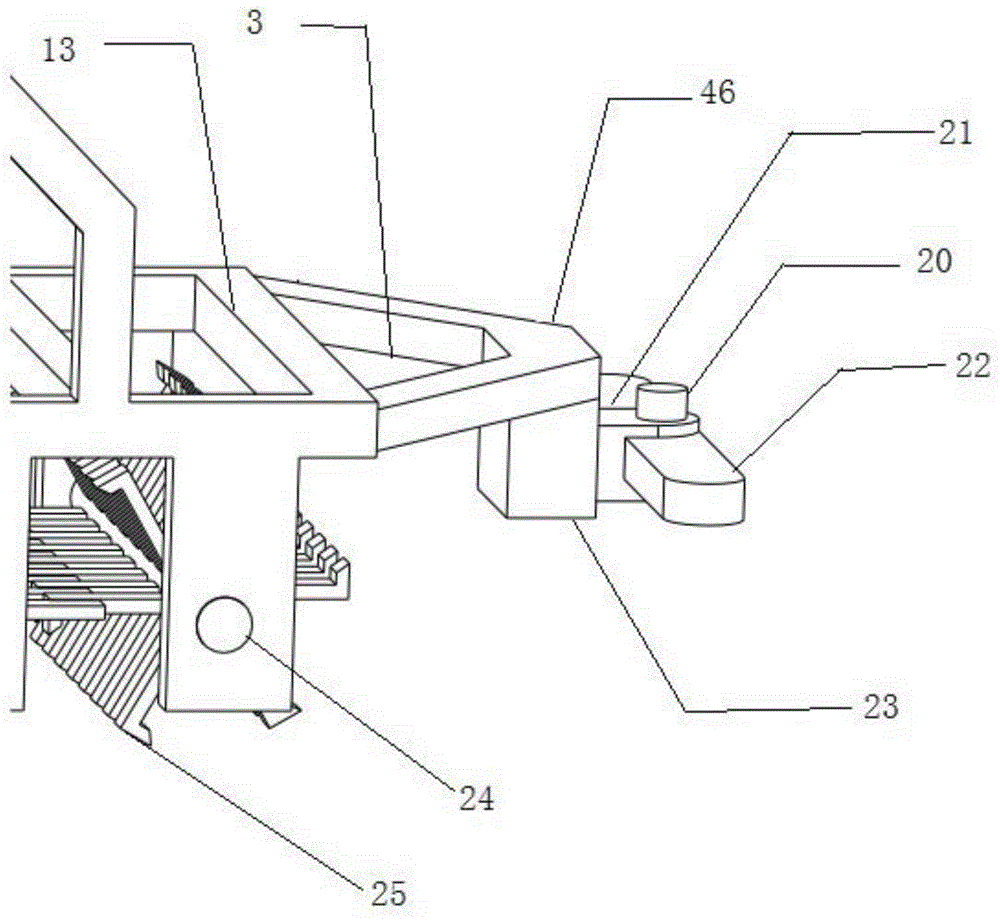

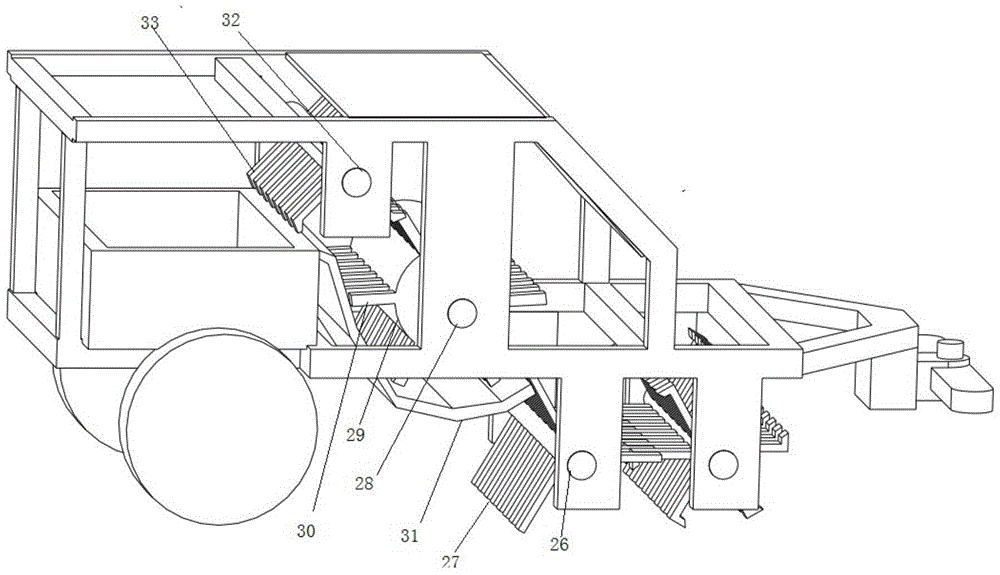

[0022] Specific implementation mode one: combine Figure 1 to Figure 5As shown, it includes vehicle frame 1, material receiving box 2, bogie 3, reducer 4, stubble picker 5, primary stubble puller 6, roller grid plate soil removal mechanism 7, secondary stubble picker 8, and second stubble picker. Level 1 drive system 9, level 1 drive system 10, wheels 11, wheel axles, U-shaped card group; front beam 13 is arranged on the front of vehicle frame 1; A axle seat 14 is arranged on the side of vehicle frame 1; A axle seat 14 is arranged behind There is a B-axis seat; a C-axis seat 16 is provided in the middle of the side of the frame 1; a D-axis seat 17 is provided on the side of the tail of the frame 11; an axle beam 18 is provided at the rear of the frame 1; the stubble picker 5 is connected to the A-axis seat 14 The first-level stubble puller 6 is connected to the B shaft seat; the roller grid plate soil removal mechanism 7 is connected to the C shaft seat 16; the second-level st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com