A scaffold material with gradient activity for osteochondral interface repair and its preparation method and application

A scaffold material and bone cartilage technology, applied in the field of scaffold materials with gradient activity and its preparation, can solve the problems of unquantifiable production, insufficient mechanical properties, cumbersome operation, etc., achieve low cost, promote bone cell calcium absorption, and preparation process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

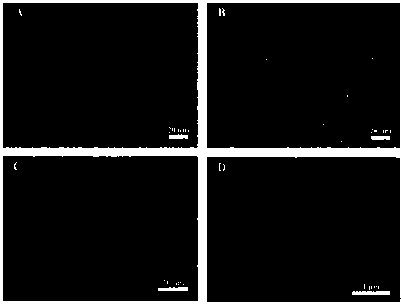

[0040] The preparation of embodiment 1 casein / calcium carbonate microsphere

[0041] Prepare 50 mM calcium salt (calcium chloride) solution and 50 mM carbonate (sodium carbonate and 8 mg / ml casein), mix the two solutions in equal volumes, stir at 600 rpm for 20 min, wash repeatedly three times and Freeze dried. The material was fixed on the sample stage, sprayed with gold, placed in the vacuum chamber of the thermal field emission scanning electron microscope, and observed at a voltage of 15 kV to obtain the SEM observation picture. products such as figure 1 As shown, the microspheres are uniformly dispersed, and the size is about 1 μm, which is a uniform spherical shape.

Embodiment 2

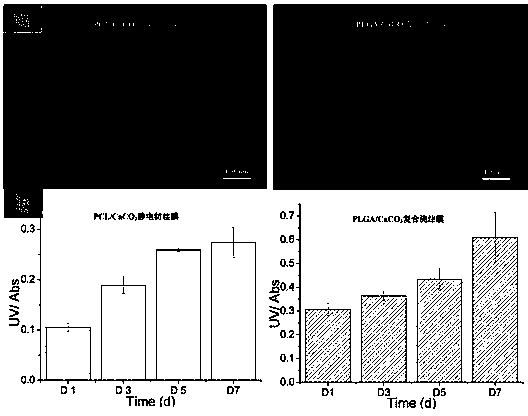

[0042] Example 2 PCL / CaCO 3 Electrospun membrane preparation

[0043] Weigh a certain mass of casein-calcium carbonate composite microspheres, disperse them in DMF at a concentration of 20% (w / v), and stir thoroughly to obtain suspension A; meanwhile, weigh twice the mass of calcium carbonate composite microspheres in PCL to dissolve In DCM, get solution B; add A to B, wherein the volume ratio of DMF and DCM is 1:3, and the final concentration of the system is 10% PCL, 5% CaCO 3 , after stirring for 12~72 h, absorb a certain amount for spinning, the driving speed is 1.0ml / h, the applied voltage value is 14kV, and the receiving distance is 11cm. After the spinning material was dried naturally, the spinning membrane was soaked in 1.5 M sodium hydroxide solution at 0-4 °C for 40 min-1 h, washed with deionized water three times, dried naturally and stored for later use.

[0044] The above samples were sterilized by immersing them in 75% alcohol for 1-3 h, and then air-dried natu...

Embodiment 3

[0045] Example 3 PLGA / CaCO 3 Composite cast film preparation

[0046] Weigh a certain mass of casein calcium carbonate composite microspheres, disperse them in DMF at a concentration of 20% (w / v), and stir them thoroughly to obtain suspension A; in DCM to obtain solution B; add A to B, wherein the volume ratio of DMF and DCM is 1:3, the final concentration of the system is 10% PLGA, 5% CaCO3, after stirring for 12~72 h, the PLGA / CaCO 3 12 mL of the mixture was placed in a clean glass Petri dish, shaken slightly to make it uniform, dried in a vacuum oven at room temperature for 2–48 h, and soaked in 1.5 M sodium hydroxide solution at 0–4°C for 10 After min~20 min, wash with deionized water three times, dry naturally and save for later use.

[0047] The above samples were sterilized by immersing them in 75% alcohol for 1-3 h, and then air-dried naturally for 12-24 h, then added sterile SBF solution into a 15 mL centrifuge tube, changed the liquid every other day, and soaked at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com