An exhaust valve spindle for an internal combustion engine, and a method of manufacturing

An exhaust valve stem, internal combustion engine technology, applied in the direction of lift valve, valve device, mechanical equipment, etc., can solve the problems of incompatibility, time-consuming HIP processing, etc., and achieve the effect of solid microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

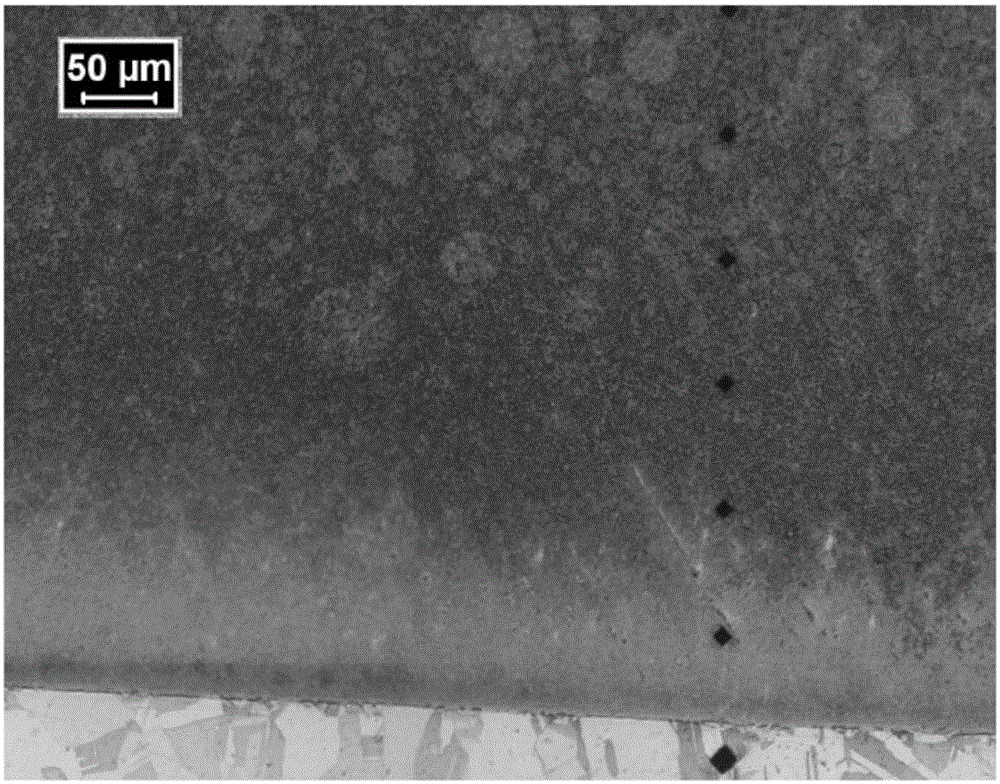

[0038] exist figure 1 and Figure 10 , the sample is removed from the HIP compacted particulate material, and the annular shape cut through the particulate can be seen. This shows that the particles retain their spherical shape during compression. A typical sign of HIP compression is that the particles are spherical and this is a result of the isostatic pressure applied during the compression. This isostatic pressure causes the particulate material to shrink in such a way that the particles do not move around the interior of the material during processing. This is a very orderly process where the mutual position among the particles is maintained. For a clearer understanding of the microstructure of the prior art, three circles are added to Figure 10 in the picture in order to draw the outlines of the three particles represented in the picture.

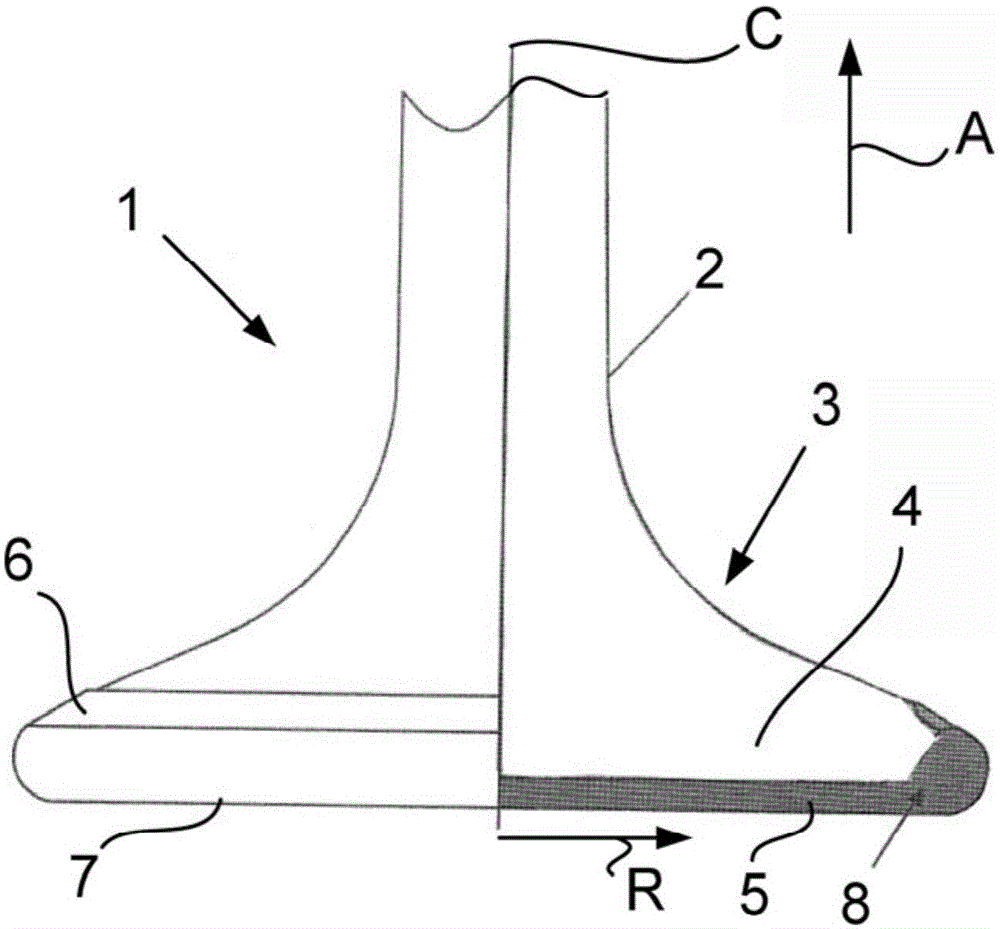

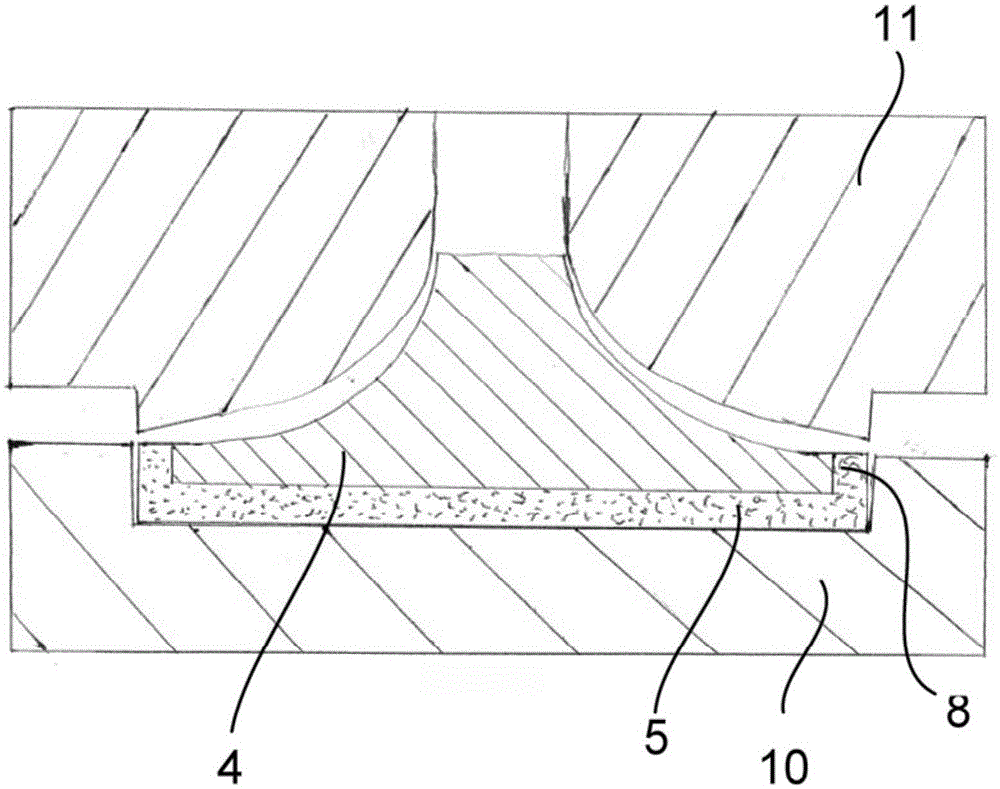

[0039] figure 2 A schematic structure of an exhaust valve stem 1 for an exhaust valve of a two-stroke crosshead engine is sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com