Shredding machine and shredding method thereof

A shredding machine and shredding technology, applied in the direction of metal processing, etc., can solve problems such as inability to work continuously for a long time, inability to clean the cutting edge, and uneven thickness of bamboo shoots, so as to achieve easy cleaning and maintenance, not easy to break, and improve The effect of the cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

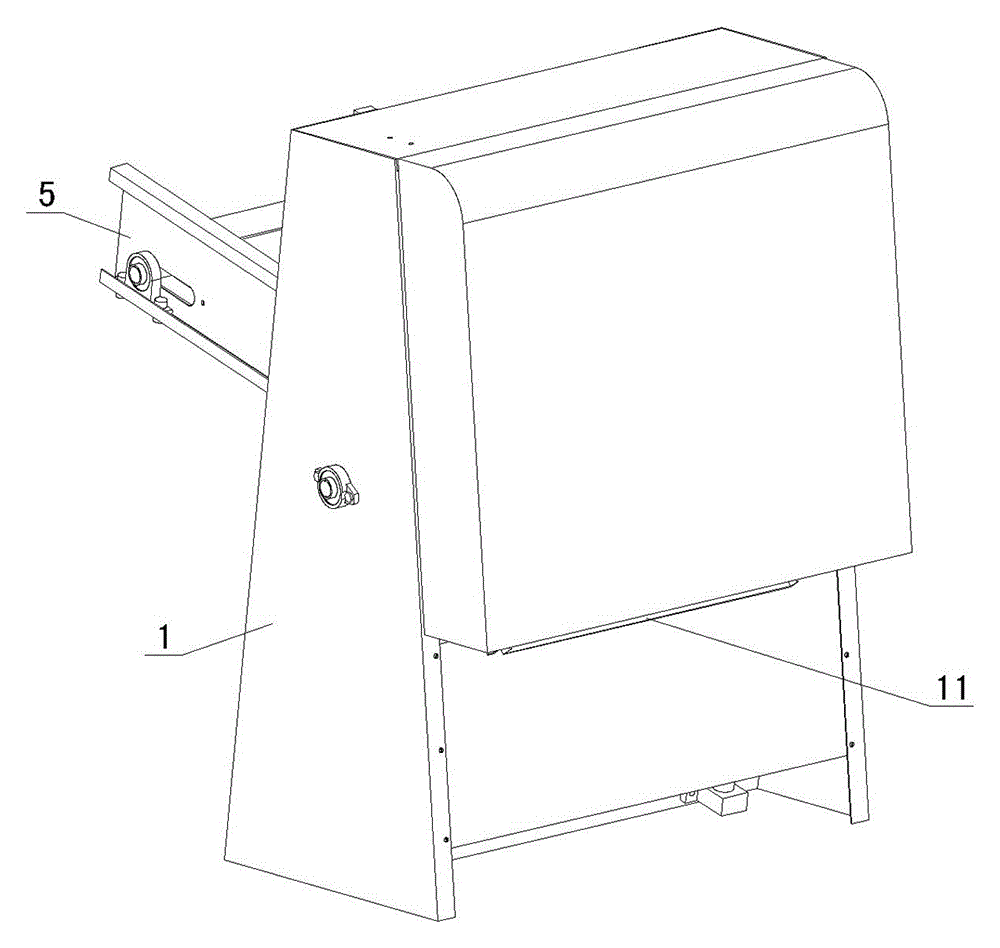

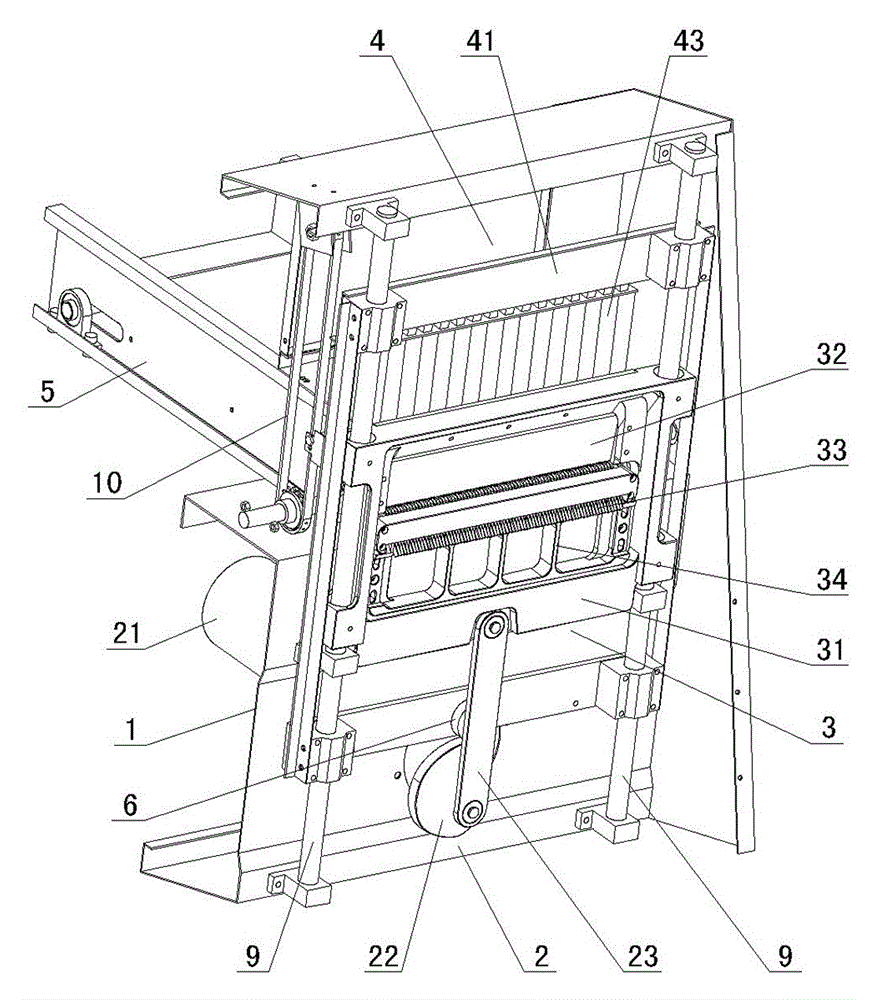

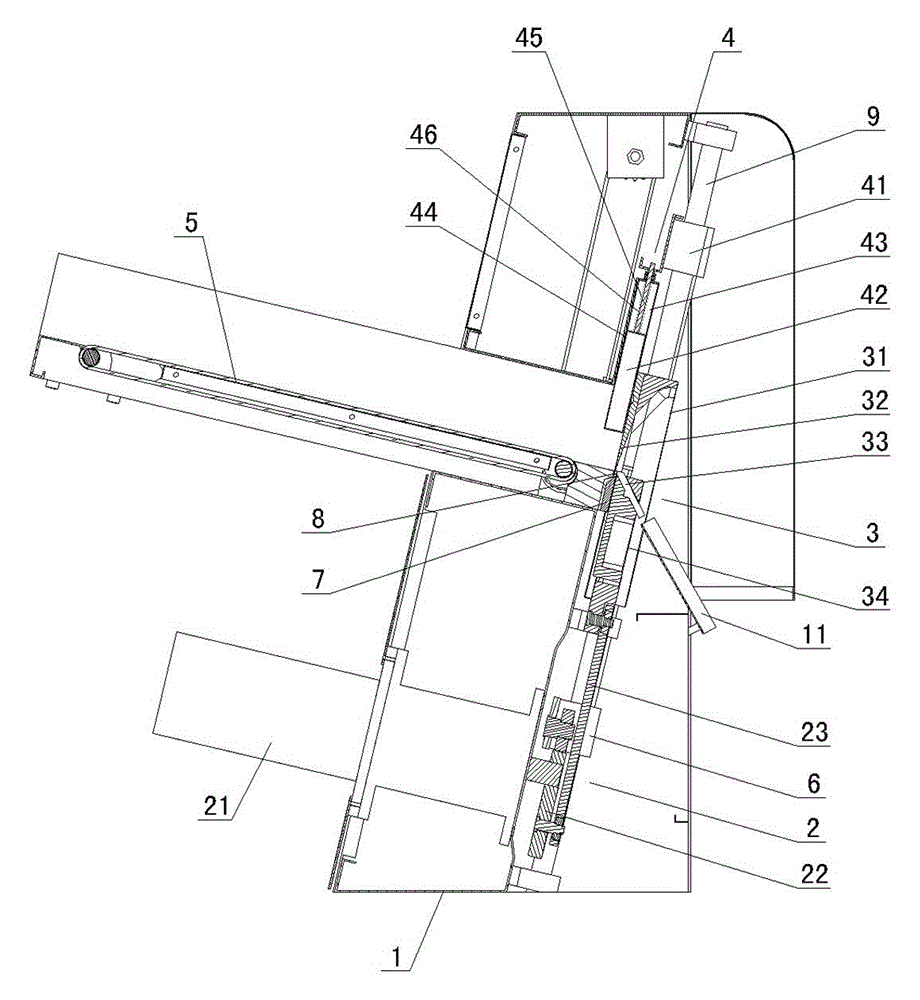

[0030] Such as Figure 1-Figure 9 As shown, the shredding machine of the present invention includes a frame 1 and a driving mechanism 2 arranged on the frame 1, a shredding mechanism 3, a pressing mechanism 4 and a feeding mechanism 5. Coordinate the actions between them to prevent the material from being deviated or turned over during the cutting process. The wire cutting mechanism 3 and the material pressing mechanism 4 are connected with the driving mechanism 2 and move up and down in a straight line under the action of the driving mechanism 2. Thus, the pressing mechanism 4 cuts the material into filaments by the downward movement of the filament-cutting mechanism 3 while pressing the material. Since the filament-cutting mechanism 3 moves up and down in a straight line, the shape of the filaments cut into is straight. The shape of strips and threads is beautiful, and the cutting is carried out by moving up and down in a straight line, which greatly improves the processing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com