Pattern tread rubber of procured remolded tire

A tread rubber and pre-vulcanization technology, applied in the field of patterned tread rubber, can solve the problems of difficult heat dissipation, falling off, and scrapped tires of the tire shoulders, and achieve the effects of reducing the shoulder bulging, eliminating prestress and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

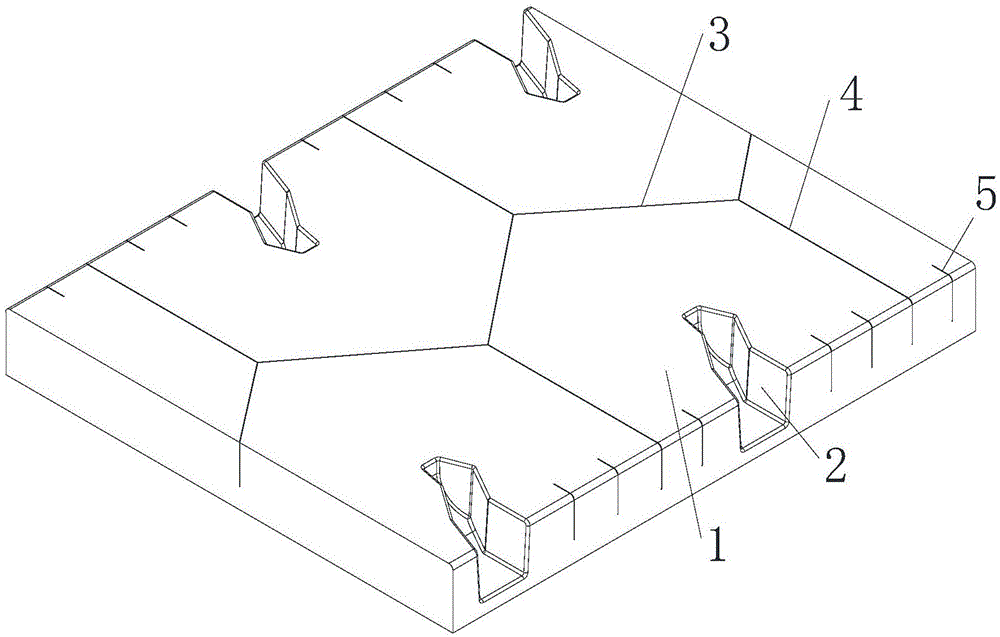

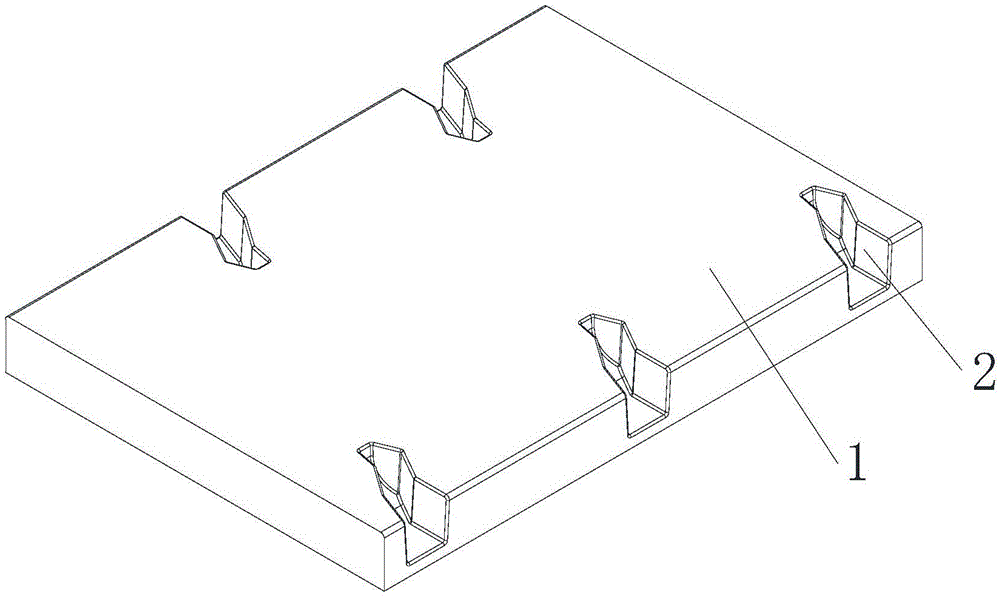

[0014] Referring to the accompanying drawings for details, this embodiment provides a patterned tread rubber for prevulcanized reconstituted tires, including a tread rubber body 1, on which a number of pattern grooves 2 are arranged, and the centerline position of the tread rubber body is Along its length direction, there is a longitudinal fold line gap 3 which is composed of a plurality of line segments connected end to end in sequence; along its width direction, there is a transverse gap 4 connected to the apex of the longitudinal fold line gap, the longitudinal fold line gap 3 and the transverse gap 4 None of them intersect with the pattern groove 2. The grooves are placed between the transverse slits one by one. Side edge slits 5 are provided on both sides of the pattern groove, and the side edge slits are along the side edges along the length direction of the tread rubber body. The number of the side edge slits is 1-5, and the side edge slits and the transverse slits are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com