Preparation method of medical film having sterilizing function

A function and material technology, applied in the field of medical film preparation, can solve the problem of rare materials for sterilization and disinfection, and achieve a significant killing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

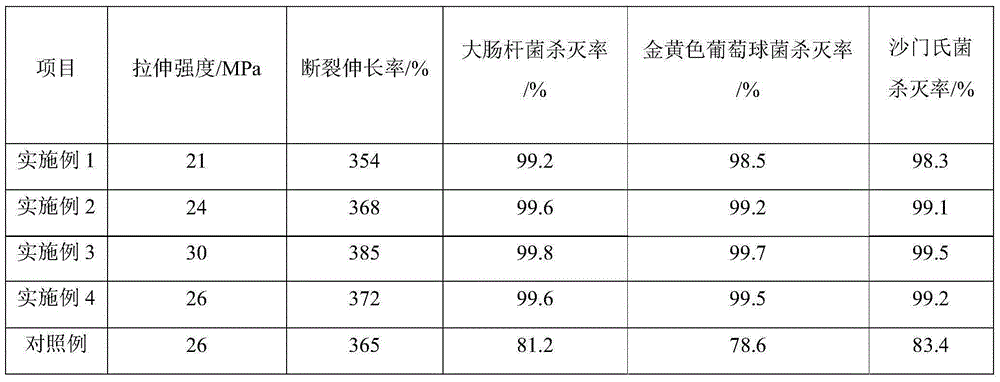

Examples

Embodiment 1

[0020] A method for preparing a medical film with sterilizing effect, comprising the following preparation steps:

[0021] Step 1: Add 80 parts of PVC in parts by weight, 3 parts of phenolic resin, 5 parts of PET, 2 parts of stearic acid, 1 part of polyvinyl alcohol and 0.5 part of paraffin into the mixer and stir and mix evenly at a stirring speed of 180 rpm. The mixing time was 20 minutes to obtain material 1;

[0022] Step 2, transfer material 1 into the reactor, add 1 part of sodium dodecylbenzenesulfonate in parts by weight, 2 parts of melamine, 0.5 part of polyacrylamide, 2 parts of hydroxypropyl methylcellulose, Heat and stir for 20 minutes under a negative pressure of 0.01MPa, the heating temperature is 60°C, the stirring speed is 100 rpm, and the temperature is lowered to room temperature to obtain material 2;

[0023] Step 3: Add 10100.2 parts by weight of antioxidant, 0.3 part of auxiliary antioxidant TNP, and 0.5 part of barium stearate into material 2, stir and m...

Embodiment 2

[0027] A method for preparing a medical film with sterilizing effect, comprising the following preparation steps:

[0028] Step 1: Add 85 parts of PVC in parts by weight, 4 parts of phenolic resin, 7 parts of PET, 3 parts of stearic acid, 2 parts of polyvinyl alcohol and 0.6 part of paraffin into the mixer and stir and mix evenly. The stirring speed is 186 rpm. The mixing time was 24 minutes to obtain material 1;

[0029] Step 2, transfer material 1 into the reactor, add 2 parts by weight of sodium dodecylbenzenesulfonate, 3 parts of melamine, 0.7 part of polyacrylamide, 3 parts of hydroxypropyl methylcellulose, Heating and stirring for 25 minutes under a negative pressure of 0.02MPa, heating temperature 66°C, stirring speed 110 rpm, and cooling down to room temperature to obtain material 2;

[0030] Step 3: Add 0.4 part by weight of antioxidant DLTP, 0.4 part of auxiliary antioxidant TPP, and 1 part of barium stearate into material 2, stir and mix evenly to obtain material 3...

Embodiment 3

[0034] A method for preparing a medical film with sterilizing effect, comprising the following preparation steps:

[0035] Step 1, 92 parts by weight of PVC, 6 parts of phenolic resin, 8 parts of PET, 5 parts of stearic acid, 2 parts of polyvinyl alcohol and 0.7 part of paraffin are added to the mixer and stirred evenly, the stirring speed is 190 rpm, The mixing time was 26 minutes to obtain material 1;

[0036] Step 2, transfer material 1 to the reactor, add 2 parts by weight of sodium dodecylbenzenesulfonate, 4 parts of melamine, 1.5 parts of polyacrylamide, 4 parts of hydroxypropyl methylcellulose, Heating and stirring for 28 minutes under a negative pressure of 0.03MPa, heating temperature 65°C, stirring speed 120 rpm, and cooling down to room temperature to obtain material 2;

[0037] Step 3: Add 10100.6 parts by weight of antioxidant, 0.4 part of auxiliary antioxidant TNP, and 1 part of barium stearate to material 2, stir and mix evenly to obtain material 3;

[0038] S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com