Polycarbonate composition and preparing method thereof

A polycarbonate and composition technology, which is applied in the field of engineering plastics, can solve problems such as affecting dimensional stability and processing fluidity, reducing material toughness, and failing to achieve a balance between rigidity and toughness. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9 and comparative example 1-6

[0068] Embodiment 1-9 and comparative example 1-6: the preparation of polycarbonate composition

[0069] 1) Weigh each component according to the formula content, and dry the polycarbonate, fibrous filler, flame retardant, and other additives that need to be pre-dried at 120°C-130°C, and the drying time is set at 4h-6h, to obtain polycarbonate, fibrous filler, flame retardant, and other additives that have been dried;

[0070] 2) Mix the pre-dried polycarbonate, fibrous filler, flame retardant, and other additives through a high-speed mixer, the mixing temperature is 30°C-50°C, and the mixing time is set at 5min-15min to obtain Uniformly mixed polycarbonate, fibrous filler, flame retardant, and other additives;

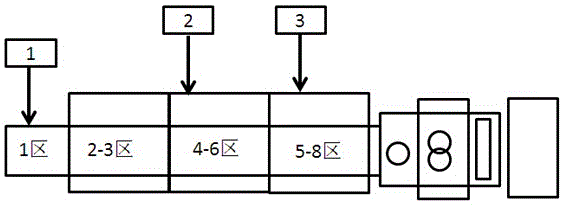

[0071] 3) Pass the homogeneously mixed polycarbonate, flame retardant, and other additives through such as figure 1 Feed port 1 shown, fibrous filler passes through as figure 1 The feed port 1, 2 or 3 shown is fed into the twin-screw extruder. The temperature con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com