Pouring sealant and preparation method for same

A technology of potting glue and epoxy resin, which is applied in the direction of adhesive, epoxy resin glue, adhesive type, etc., to achieve the effect of small gap permeability, fast flow speed and excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Accurately weigh the following raw materials, bisphenol A epoxy resin (E51) 50g, n-butyl glycidyl ether agent 7.5g, β-(3,4-epoxycyclohexyl)ethyltrimethoxysilane 2g, Put 0.5g of carbon black into the reaction kettle, mix at room temperature for 30 minutes, then weigh 5g of TATSUMORI’s XR-08P, TSS-625g into the reaction kettle, mix at room temperature for 3 hours, then weigh 10g of ADEKA’s EH-4360s, add to the reaction kettle In the process, at a temperature of 25°C, a vacuum degree of -0.07MPa, and a rotation speed of 800 rpm, stir and mix for 1 hour to obtain the product.

Embodiment 2

[0024] Accurately weigh the following raw materials, 30g of novolac epoxy resin (F51), 10g of tert-butyl glycidyl ether, 5g of γ-glycidyloxypropyltrimethoxysilane, and 0.5g of carbon black, and put them into the reaction kettle. Mix at low temperature for 30 minutes, then weigh 5g of TATSUMORI's XR-18P, TSS-640g into the reactor, mix at room temperature for 3 hours, then weigh 9.5g of ADEKA's EH-43709, add it to the reactor, at a temperature of 25 ° C, vacuum degree - 0.07MPa, rotating speed 800 rpm, stirring and mixing for 1 hour to obtain the product.

Embodiment 3

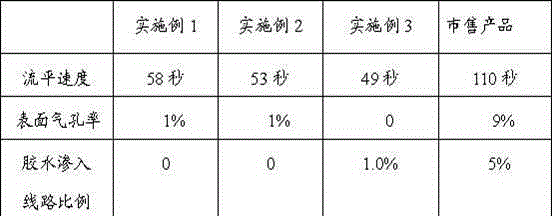

[0027] Specific test examples

[0028] The performances of the above-mentioned Examples 1-3 of the present invention and the commercially available potting compound were tested by the following test.

[0029] Test Example 1 Leveling Speed Test

[0030] Put the glue into the 2cmx2cm mold box with the wiring harness embedded in it, and time it with a stopwatch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com