Preparation method of broad bean flower extract liquid for tobacco

A broad bean flower and extract technology, which is applied in the field of cigarette flavors and fragrances, can solve problems such as the lack of broad bean flower extract, and achieve the effects of improving cigarette smoking quality, soft and delicate smoke, and improving application effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

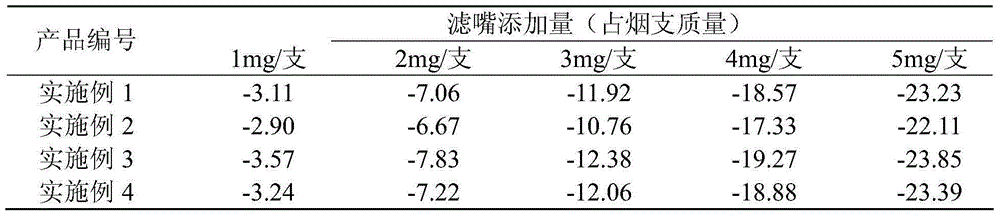

Examples

preparation example Construction

[0021] A method for preparing an extract of broad bean flower for tobacco, characterized in that: the method for preparing the extract of broad bean flower for tobacco comprises the following steps:

[0022] A. Dry and pulverize the commercially available broad bean flower medicinal material and pass through a 60-120 mesh screen to obtain broad bean flower powder;

[0023] B. Extract broad bean flower powder and citric acid aqueous solution at a material-to-liquid ratio of 1:15 to 30 at a temperature of 80 to 100°C for 2 to 5 hours, and filter to remove the residue to obtain the broad bean flower primary extract;

[0024] C. Concentrate the initial extract of broad bean flower in step B to a solid content of 25-35%, add 95% ethanol solution, stir evenly, and set aside for 16-24 hours at 4°C for alcohol precipitation, and then use a ceramic membrane to filter, Concentrate the filtrate under reduced pressure until there is no ethanol smell to obtain the broad bean flower extract...

Embodiment 1

[0031] A. The broad bean flower medicinal material available in the market is dried and pulverized, and passed through a 100-mesh sieve to obtain broad bean flower powder.

[0032] B. Use citric acid aqueous solution with a pH of 5.0 as the extraction solvent, put broad bean flower powder and citric acid aqueous solution into an extraction container according to the ratio of solid to liquid 1:30, extract at a temperature of 90°C for 3 hours, and filter to remove the residue to obtain broad bean Flower initial extract.

[0033] C. Concentrate the initial extract of broad bean flower in step B to a solid content of 25%, add 95% ethanol so that the volume fraction of ethanol reaches 70% after the system is evenly mixed, and stand at 4°C for 16h to carry out alcohol precipitation. Then select a 0.5 μm ceramic membrane for filtration treatment, and concentrate the filtrate under reduced pressure until it has no ethanol smell, which is the broad bean flower extract of the present in...

Embodiment 2

[0035] A. Drying and pulverizing the commercially available broad bean flower medicinal material and passing through a 120-mesh sieve to obtain broad bean flower powder.

[0036] B. Use citric acid aqueous solution with a pH of 6.0 as the extraction solvent, put broad bean flower powder and citric acid aqueous solution into an extraction container according to the ratio of solid to liquid 1:25, extract at a temperature of 100°C for 3 hours, and filter to remove the residue to obtain broad bean Flower initial extract.

[0037] C. Concentrate the initial extract of broad bean flower in step B to a solid content of 35%, add 95% ethanol so that the volume fraction of ethanol reaches 80% after the system is evenly mixed, and stand at 4°C for 18h for alcohol precipitation. Then select a 0.4 μm ceramic membrane for filtration treatment, and concentrate the filtrate under reduced pressure until it has no ethanol smell, which is the broad bean flower extract of the present invention. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com