A method for manufacturing an environmentally friendly non-wrapped heat-not-burn naked pod

A heat-not-burn and manufacturing method technology, applied in the field of pod manufacturing, can solve the problems of harmful substances in the smoke, environmental pollution, complex structure, etc., and achieve the effects of reducing the difficulty of the production process, good aroma, and soft and delicate smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

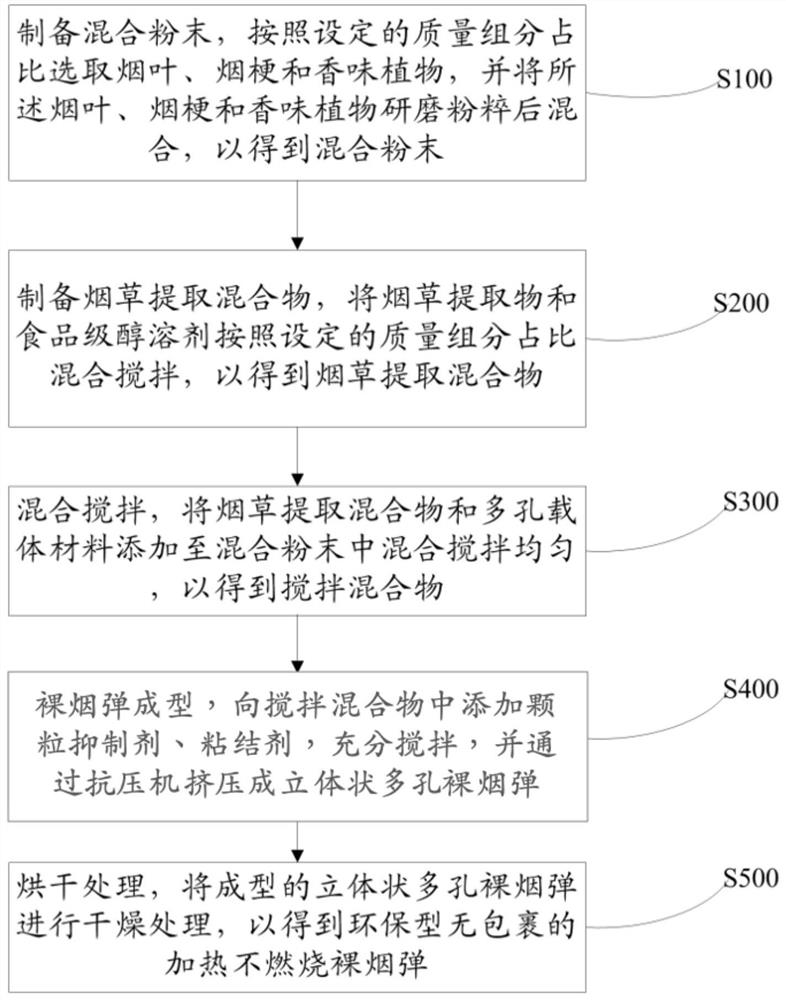

Method used

Image

Examples

Embodiment 1

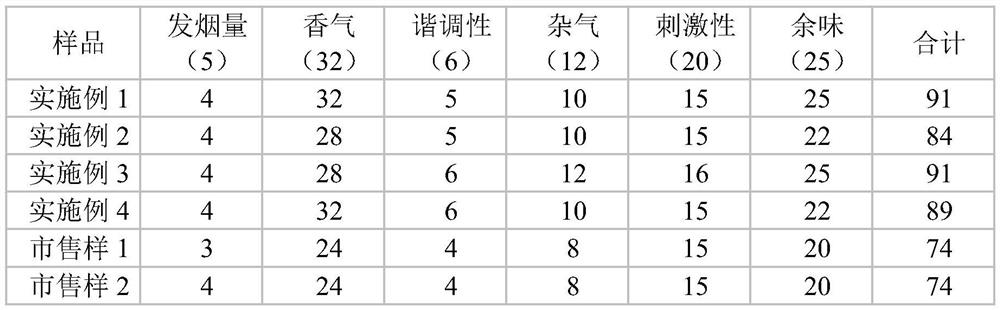

[0065] Example 1: The following components are all in accordance with the mass ratio of the contained components, including 5 parts of tobacco leaf powder (composed of upper tobacco leaf powder, middle tobacco leaf powder, and lower tobacco leaf powder in a weight ratio of 1:3:1), 2 parts of tobacco leaf powder stem powder, 1 part tea powder, 1 part porous ceramic powder, and 1 part tobacco extract blend.

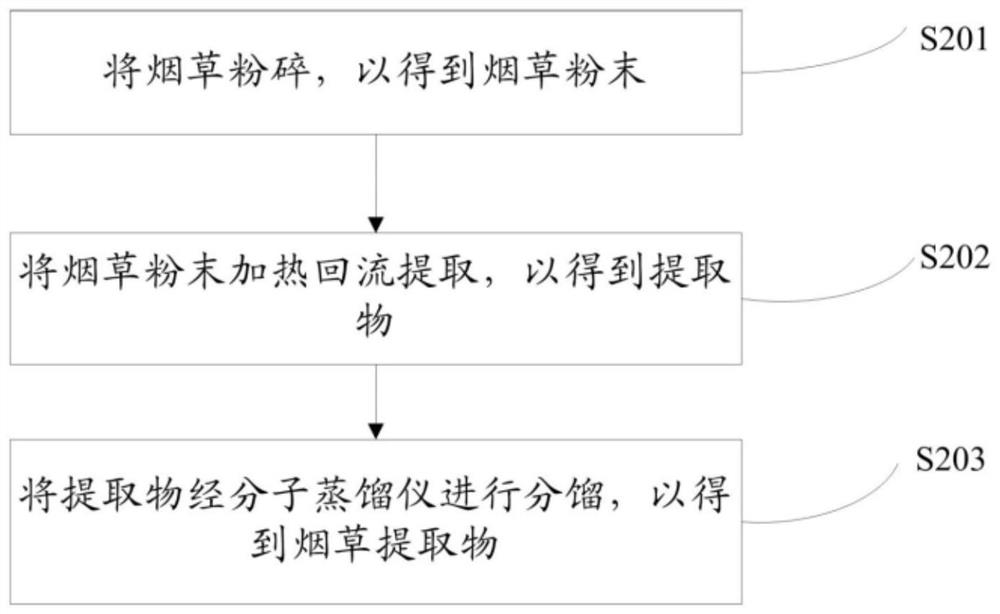

[0066] Select 7 parts of tobacco leaves (composed of upper tobacco leaves, middle tobacco leaves, and lower tobacco leaves in a weight ratio of 1:3:1, or at least one of them can be selected), 2 parts of tobacco stems, and 1 part of tea leaves and mix them uniformly as raw materials for mixed powder; Wherein the mixed plant raw material is put into a grinder to pulverize, and passed through an 80-mesh sieve to obtain a mixed powder, which is set aside. The tobacco is crushed, heated and refluxed for extraction, the obtained extract is fractionated by a molecular distillatio...

Embodiment 2

[0067] Example 2: The following components are all in accordance with the mass ratio of the components contained. A heat-not-burn environmentally friendly heat-not-burn pod includes 6 parts of tobacco leaf powder (from the upper tobacco leaf powder, middle tobacco leaf powder, and lower tobacco leaf powder according to The weight ratio is 1:3:1, and at least one of them can also be selected), 1 part of tobacco stem powder, 1 part of Panax notoginseng flower stalk powder, 1 part of macroporous resin and 1 part of tobacco extraction mixture.

[0068]Select 7 parts of tobacco leaves (composed of upper tobacco leaves, middle tobacco leaves, and lower tobacco leaves in a weight ratio of 1:3:1), 1 part of tobacco stems, and 2 parts of Panax notoginseng pedicels and mix them evenly; put the mixed plant raw materials into a grinder to pulverize, Pass through a 80-mesh sieve to obtain a mixed powder for subsequent use. Tobacco is pulverized, heated and refluxed for extraction, and the ...

Embodiment 3

[0069] Embodiment 3: The following components are all in accordance with the mass ratio of the components contained. A heat-not-burn environmentally friendly heat-not-burn pod includes 5 parts of tobacco leaf powder (from the upper part of the tobacco leaf powder, the middle part of the tobacco leaf powder, and the lower part of the tobacco leaf powder. The weight ratio is 1:3:1), 1 part of tobacco stem powder, 1 part of tortoise flower powder, 2 parts of zeolite powder and 1 part of tobacco extract mixture.

[0070] Select 5 parts of tobacco leaves (composed of upper tobacco leaves, middle tobacco leaves, and lower tobacco leaves in a weight ratio of 1:3:1, or at least one of them), 2 parts of tobacco stems, and 3 parts of tortoise flowers and mix evenly; mix the mixed The plant raw material is put into a grinder to pulverize, and passed through an 80-mesh sieve to obtain a mixed powder, which is set aside. Tobacco is pulverized, heated and refluxed for extraction, and the ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com