Method for assisting laser cladding process by virtue of static magnetic field

A laser cladding, magnetic field assisted technology, applied in the direction of metal material coating process, coating, etc., to achieve the effect of optimizing the comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

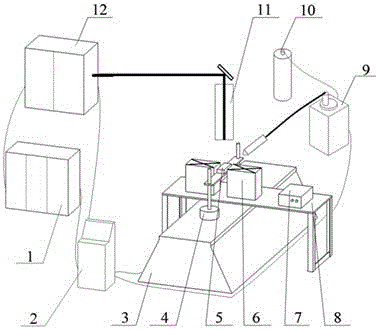

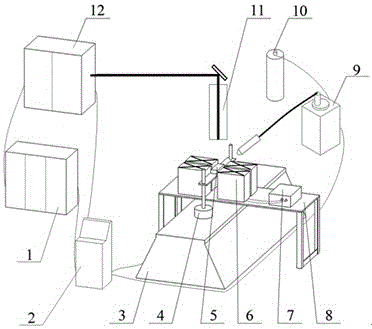

Method used

Image

Examples

Embodiment 1

[0031] (1) Grinding, degreasing, cleaning, and drying the 45 steel cladding substrate with a size of 90mm×15mm×15mm;

[0032] (2) Fe55 alloy powder (the mass fractions of each element are: Cr18.13%, Si2.94%, C0.8%, Mn0.69%, Ni0.43%, FeBal.) placed in a drying oven at 80 ° C to dry 10h, after it cools down, place a preset layer with a size of 80mm×5mm×1mm on the surface of the 45 steel substrate, and place it in a drying oven at 80°C for 10h, then take it out and cool it for later use;

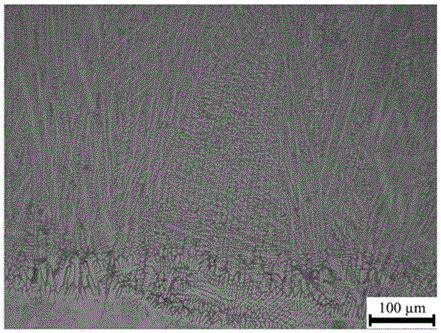

[0033] (3) Fix the cladding substrate on the sample fixture, adjust the position of the sample fixture relative to the magnetic field generator, make the area to be clad on the cladding substrate be at the center of the magnetic pole, and make the surface coating of the cladding substrate The length direction is perpendicular to the central axis of the magnetic pole, and the laser beam is focused and irradiated on the cladding substrate (laser process parameters: laser power 4.0kW, laser scanni...

Embodiment 2

[0036] (1) Grinding, degreasing, cleaning, and drying the 45 steel cladding substrate with a size of 90mm×15mm×15mm;

[0037] (2) Fe55 alloy powder (the mass fractions of each element are: Cr18.13%, Si2.94%, C0.8%, Mn0.69%, Ni0.43%, FeBal.) placed in a drying oven at 90 ° C to dry 8h, after it cools down, place a preset layer with a size of 80mm×5mm×1mm on the surface of 45 steel base material, and place it in a drying oven at 80°C for 10h, then take it out and cool it for later use;

[0038](3) Fix the cladding substrate on the sample fixture, adjust the position of the sample fixture relative to the magnetic field generator, make the area to be clad on the cladding substrate be at the center of the magnetic pole, and make the surface coating of the cladding substrate The length direction is perpendicular to the central axis of the magnetic pole, and the laser beam is focused and irradiated on the cladding substrate (laser process parameters: laser power 3.0kW, laser scanning...

Embodiment 3

[0041] (1) Grinding, degreasing, cleaning, and drying the 45 steel cladding substrate with a size of 90mm×15mm×15mm;

[0042] (2) Fe55 alloy powder (mass fractions of each element are: Cr18.13%, Si2.94%, C0.8%, Mn0.69%, Ni0.43%, FeBal.) placed in a drying oven at 100 ° C to dry 6h, after it cools down, place a preset layer with a size of 80mm×5mm×1mm on the surface of 45 steel base material, and place it in a drying oven at 80°C for 10 hours, then take it out and cool it for later use;

[0043] (3) Fix the cladding substrate on the sample fixture, adjust the position of the sample fixture relative to the magnetic field generator, make the area to be clad on the cladding substrate be at the center of the magnetic pole, and make the surface coating of the cladding substrate The length direction is perpendicular to the central axis of the magnetic pole, and the laser beam is focused and irradiated on the cladding substrate (laser process parameters: laser power 5.0kW, laser scann...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com