An anti-yellowing agent for nylon

An anti-yellowing agent, nylon technology, used in textiles, papermaking, fiber processing, etc., can solve the problems of service life discount, poor anti-yellowing performance, high formulation cost, and achieve low formulation cost, human body and environment friendly, and maintenance. Effects of Whiteness and Vibrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] An anti-yellowing agent for nylon is composed of fatty alcohol polyoxyethylene ether AEO-7 15%, carbohydrazide 2.5wt%, propylene glycol methyl ether 10wt% and water 72.5wt%.

[0012] During preparation, the above-mentioned components are directly stirred and mixed in a container to obtain the finished product of the anti-yellowing agent.

Embodiment 2

[0014] An anti-yellowing agent for nylon, which consists of 10% Span-20, 5wt% carbohydrazide, 15wt% dipropylene glycol methyl ether and 70wt% water.

[0015] During preparation, the above-mentioned components are directly stirred and mixed in a container to obtain the finished product of the anti-yellowing agent.

Embodiment 3

[0017] An anti-yellowing agent for nylon is composed of Tween-60 12%, carbohydrazide 7wt%, dipropylene glycol methyl ether 10wt% and water 71wt%.

[0018] During preparation, the above-mentioned components are directly stirred and mixed in a container to obtain the finished product of the anti-yellowing agent.

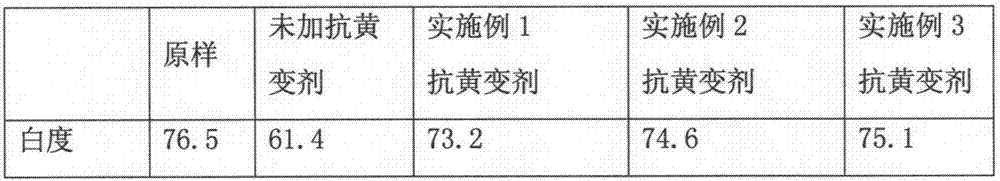

[0019] Taking white nylon woven fabric as an example, the white nylon woven fabric is subjected to high temperature setting.

[0020] Sizing process: the anti-yellowing agent solution of 1-3 of the present embodiment (pressure 2kg / cm 2 , Liquid rate 50-60%), pre-baked in a heat setting machine at 100°C for 2 minutes and then set at 190°C for 60 seconds, and finally tested the whiteness of the white nylon fabric treated with anti-yellowing agent and untreated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com