A waterproof device for gaps between bimetallic composite pipe liquid-expanded base liner pipes

A bimetallic composite pipe and waterproof device technology, applied in the direction of valve devices, functional valve types, control valves, etc., can solve the problems of increasing manufacturing costs, complex forming processes, and limiting free deformation of liners, achieving high reliability and optimization Waterproof technology, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

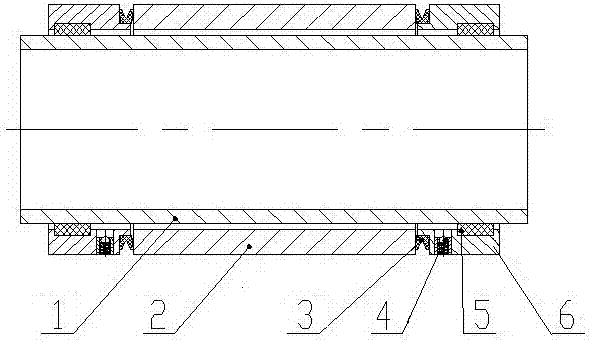

[0023] In order to overcome the defects of the base liner pipe waterproofing device of the existing bimetallic composite pipe, such as figure 1 As shown, this embodiment provides a bimetallic composite pipe liquid-expanded base liner gap waterproof device, including a base pipe 2 and a liner 1 located in the base pipe 2 and coaxial with the base pipe 2, the base pipe Two ends of 2 are respectively provided with a sealing pressure ring 6 sleeved on the liner 1, and a waterproof sealing ring 5 sleeved on the liner 1 is provided between the sealing pressure ring 6 and the liner 1; A first through hole 7 is opened in the radial direction, and an exhaust valve 4 for discharging the air between the inner wall of the base pipe 2 and the outer wall of the liner 1 is arranged in the first through hole 7 .

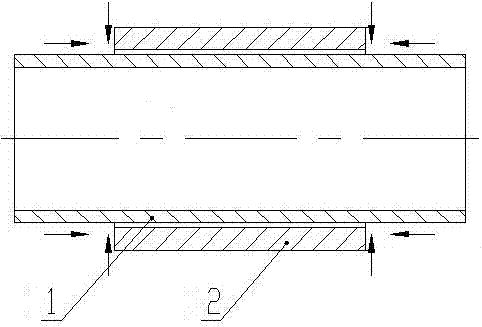

[0024] Such as figure 2 , the arrows in the figure indicate the main channels for water and gas to enter the bimetallic composite pipe, but the key to producing bimetallic composi...

Embodiment 2

[0028] On the basis of embodiment 1, further, such as figure 1 and Figure 4 As shown, the sealing pressure ring 6 is provided with a diameter-reducing part 8 on the side close to the end of the base pipe 2, and the end-face seal 3 of the base pipe is sleeved on the diameter-reducing part 8, and the end face seal 3 of the base pipe is sealed with the end of the base pipe 2. touch.

[0029] The sealing pressure ring 6 is tightly fixed on the waterproof sealing ring 5, and a certain axial force is applied to the base pipe end face seal 3 to ensure that water will not enter from the end face of the base pipe 2, and the sealing pressure ring 6 cooperates with the base pipe end face seal 3 The use can further ensure the waterproof effect of the liquid-expanded-formed-based liner gap waterproof device for bimetallic composite pipes.

Embodiment 3

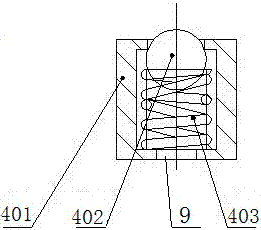

[0031] On the basis of Example 1, such as image 3 As shown, the exhaust valve 4 is a one-way valve, which is composed of a valve seat 401, a sealing steel ball 402, and a spring 403. The sealing steel ball 402 and the spring 403 are all located in the valve seat 401, and one end of the spring 403 is connected to the valve seat 401. The inner wall is fixedly connected, and the other end is connected with the sealing steel ball 402; the second through hole 9 coaxial with the first through hole 7 and the spring 403 is opened on the valve seat 401, and the diameter of the sealing steel ball 402 is larger than the second through hole 9 in diameter, the sealing steel ball 402 is located near the end of the liner 1.

[0032] It should be noted that the exhaust valve 4 is located in the first through hole 7 of the sealing pressure ring 6, and the sealing steel ball 402 is tightly pressed in the valve seat 401 by the force of the spring 403, and is in contact with the second through h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com