Baking device for electricity generating coal or power coal

A drying device and steam coal technology, applied in drying, drying machine, drying solid materials, etc., can solve the problems of lowering the drying quality of lignite, easy short circuit of hot air flow, jumping out of the machine from the middle, heat loss and other problems , to achieve the effect of complete and practical structure, simple structure, and prevention of hot air short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

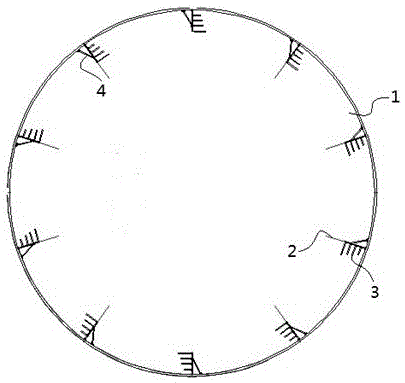

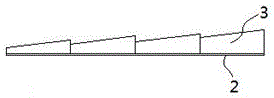

[0014] A lignite rotary dryer, comprising a rotary cylinder 1, the inner wall of the rotary cylinder 1 is provided with several lifting devices for lifting materials, and the lifting devices include a lifting fixed plate 2 and a lifting fixed plate 2 vertically arranged The lifting device also includes a fixed support frame 4 for fixing and supporting the lifting fixed plate 2 on the inner wall of the rotary cylinder 1.

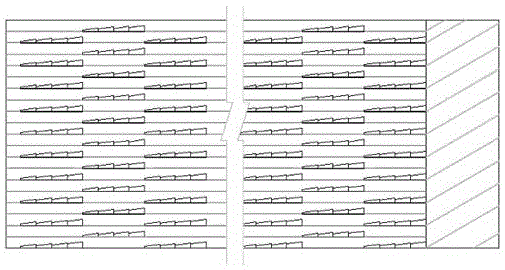

[0015] In this embodiment, there are more than four lifting plates 3 with a trapezoidal cross-section and are uniformly and vertically arranged on the above-mentioned lifting fixing plate 2 . like image 3 As shown, the lifting device is arranged on the inner wall of the above-mentioned rotary cylinder 1 in a staggered seam.

[0016] Due to the flammable, explosive and high-yield large-scale development of lignite, we still use single-drum rotary

[0017] Dryer. Therefore, this embodiment adopts a reasonable inclination of the rotary dryer, generally 3% to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com