Heat pump type tail heat recycling through counterflow drying machine

A tail heat recovery and dryer technology, applied in the field of dryers, can solve the problems of personnel and equipment safety accidents, strong vibration, etc., and achieve the effects of extending service life, high strength and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Now in conjunction with accompanying drawing, the present invention is described in further detail.

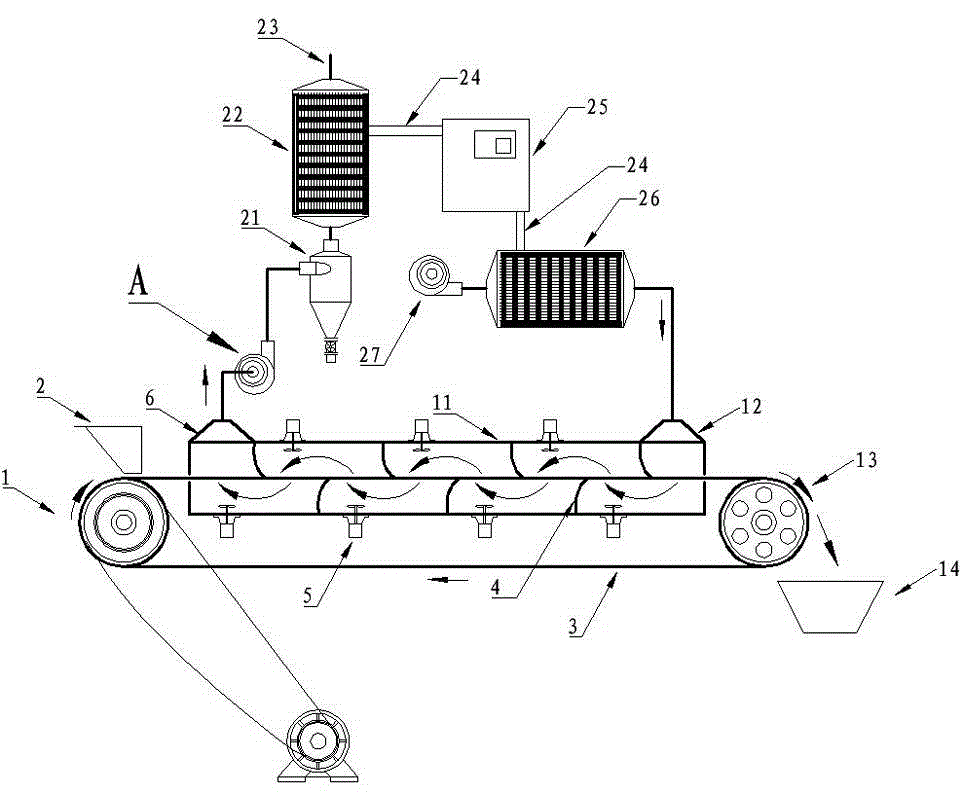

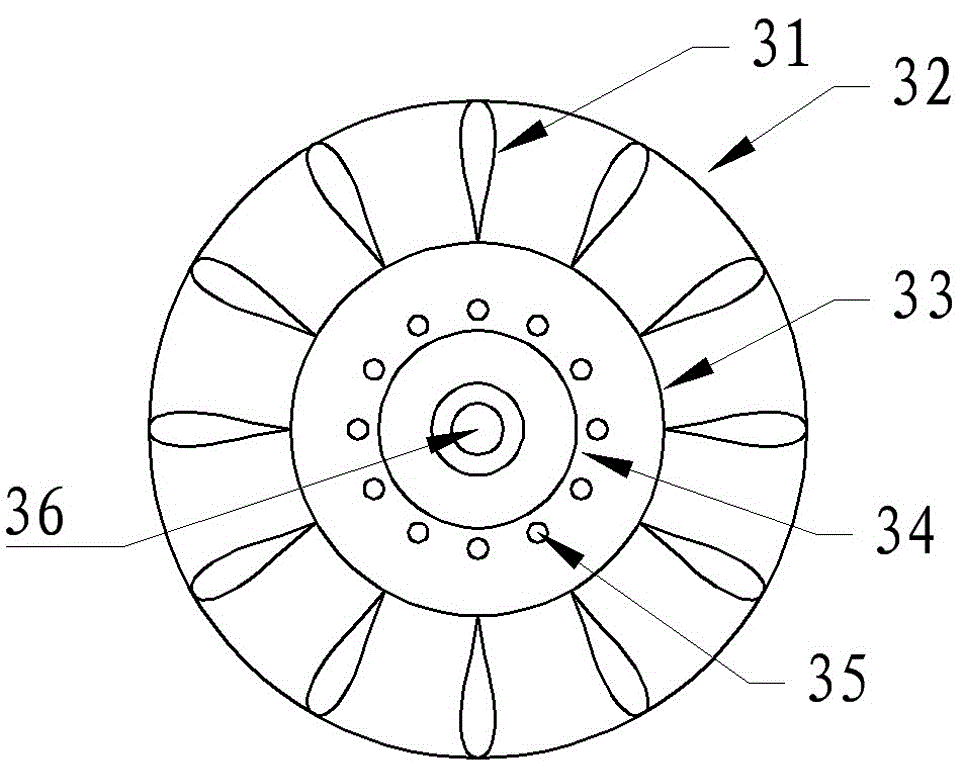

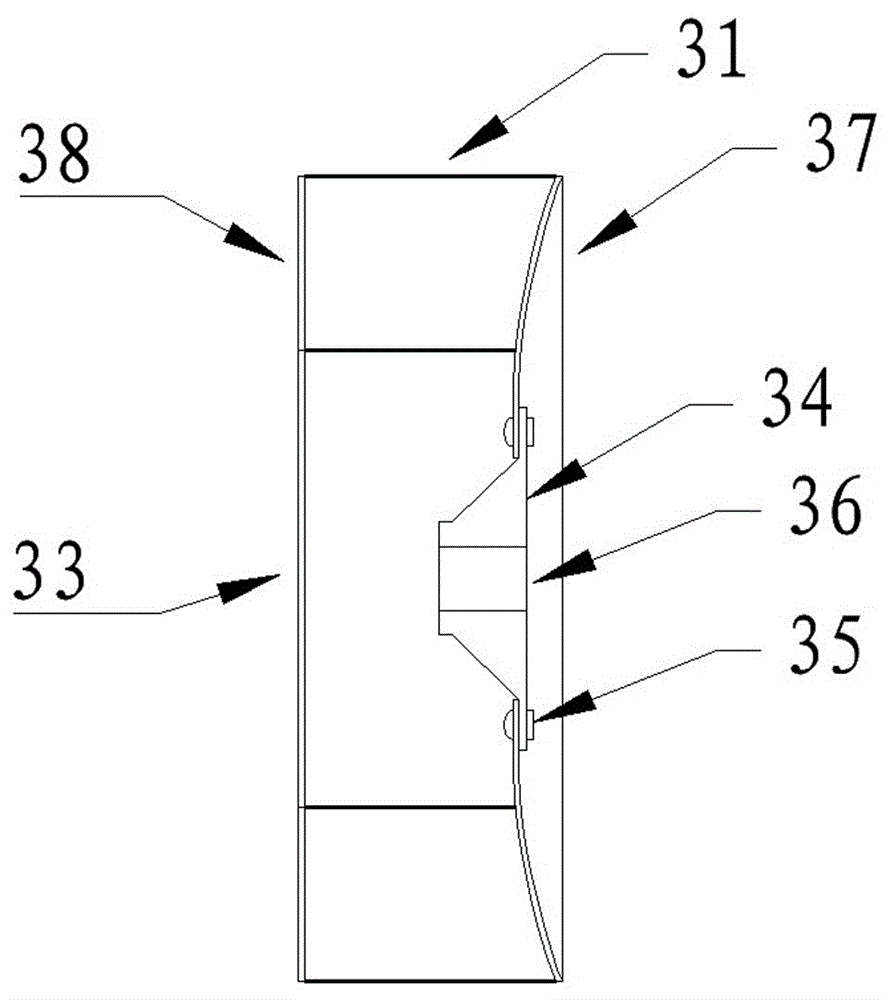

[0030] Such as figure 1 , figure 2 , image 3 with Figure 4 The shown heat pump tail heat recovery penetrating counterflow dryer includes a dryer box 11 and an induced draft fan A. The two ends of the dryer box 11 are respectively provided with an exhaust hood 6 and an air inlet hood 12, and the exhaust hood 6 is connected to the induced draft fan. A, the induced draft fan A is emptied after being connected to the evaporator 22 of the heat pump system through the cyclone dust collector 21; The end is connected to the air inlet cover 12 through the condenser 26; the induced draft fan A includes a fan impeller 41 and a casing 45, and the fan impeller 41 includes an impeller back plate 37, an impeller panel 38 and a blade 31, and the blade 31 is arranged in the radial direction of the impeller shaft, Center symmetrical hollow anti-drop shape, the impeller back plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com