An Adaptive Calibration Method of Infrared Focal Plane Array with Variable Integration Time

A technology of infrared focal plane and integration time, which is applied in the field of infrared imaging, can solve problems such as unsatisfactory correction effects, and achieve the effects of small error, improved uniformity, and high correction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

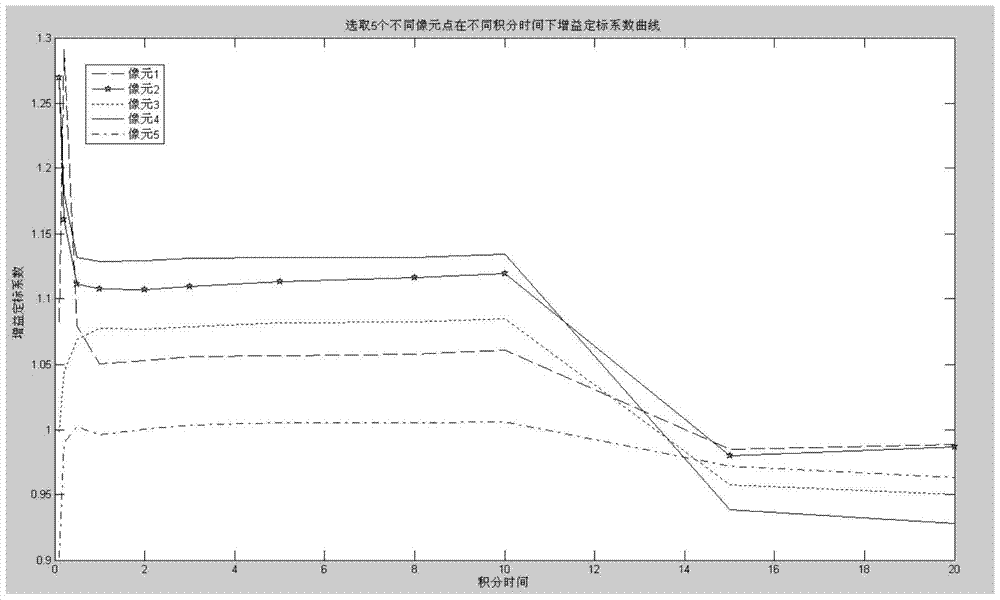

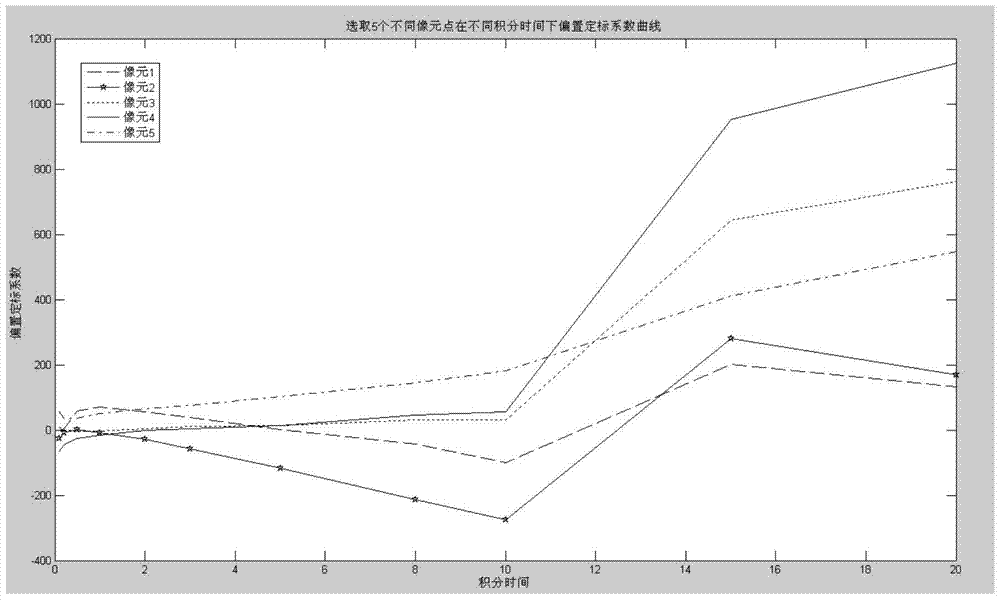

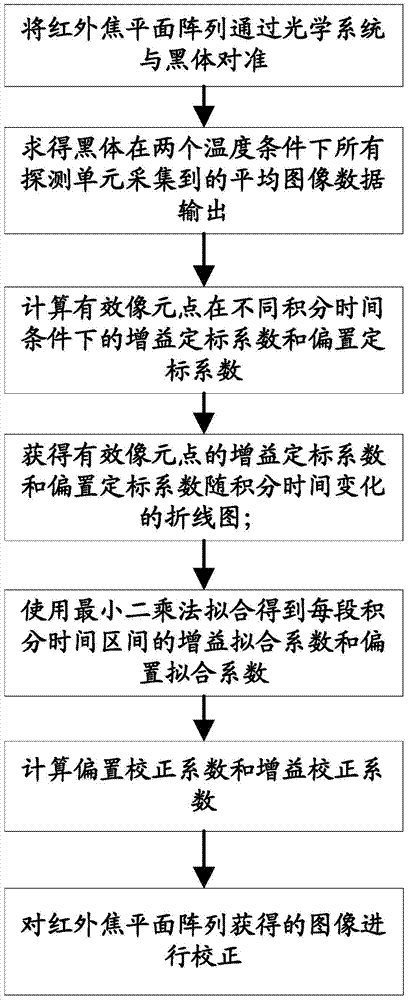

Method used

Image

Examples

Embodiment

[0106] At different temperatures, the integration time was modified, and the residual amount of image non-uniformity was tested before calculation and correction, after correction by the existing correction method and after correction using the method of the present invention. The test results are shown in Tables 1 to 3. Among them, Table 1 is the statistical table of the non-uniformity residual amount of the original image before correction, Table 2 is the statistical table of the non-uniformity residual amount after correction by the existing method, and Table 3 is the correction value of the present invention. Post-inhomogeneity residual statistical table;

[0107] Table 1

[0108] T / Int

0.1

1

2

4

6

10

15

20

0.0646

0.0920

0.1403

0.0946

0.0984

0.0978

0.0721

22

0.0653

0.0886

0.1318

0.0904

0.0938

0.0941

0.0685

27

0.0667

0.0829

0.1149

0.0847

0.0883

0.0885

0.0637

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com