Image detection method of printed circuit board

A technology for image detection and printed substrates, which is applied in the direction of optical testing for flaws/defects, can solve problems such as misjudgment, and achieve the effect of improving detection accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Relevant detailed description and technical content of the present invention, now just explain as follows with respect to matching drawing:

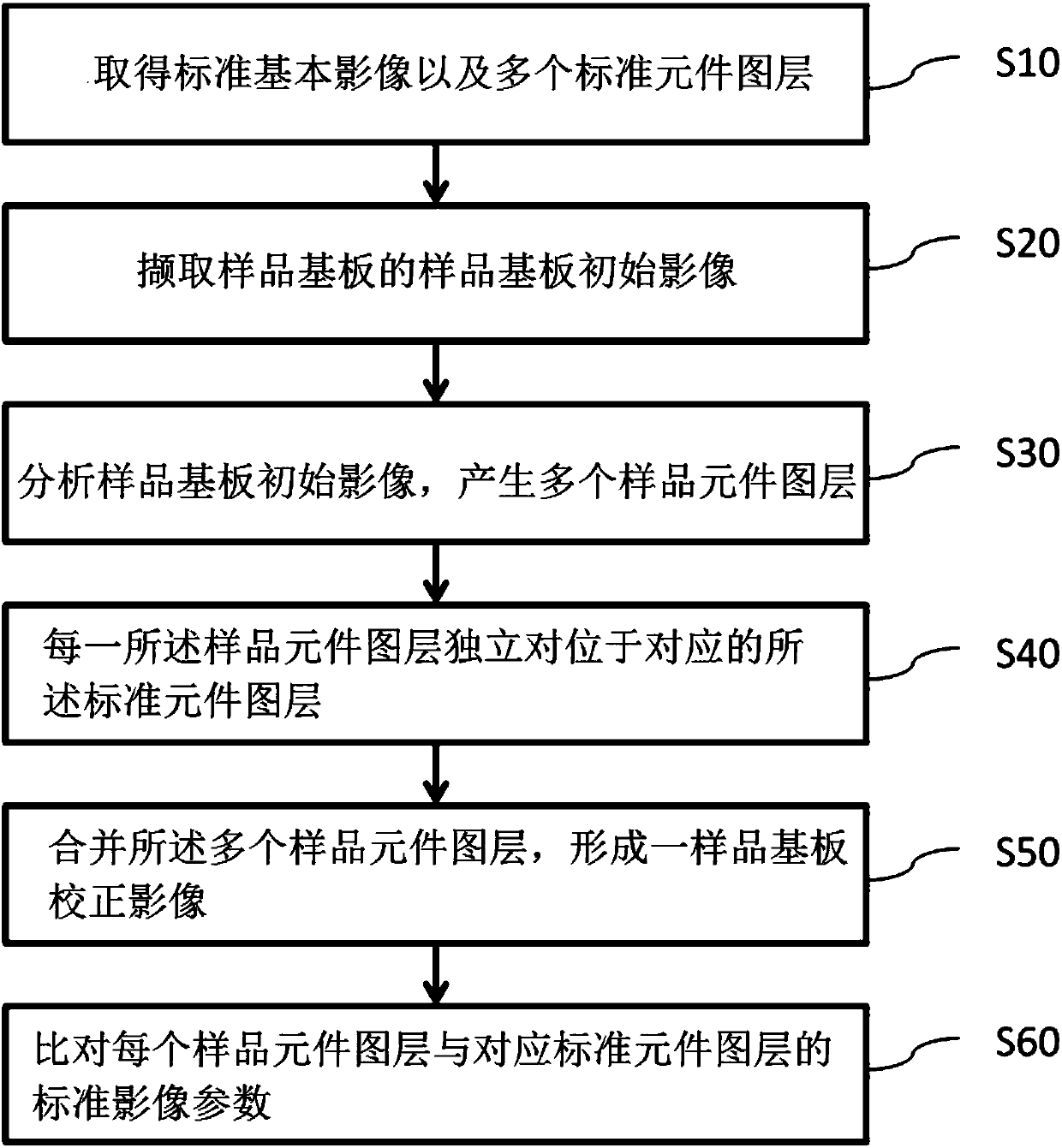

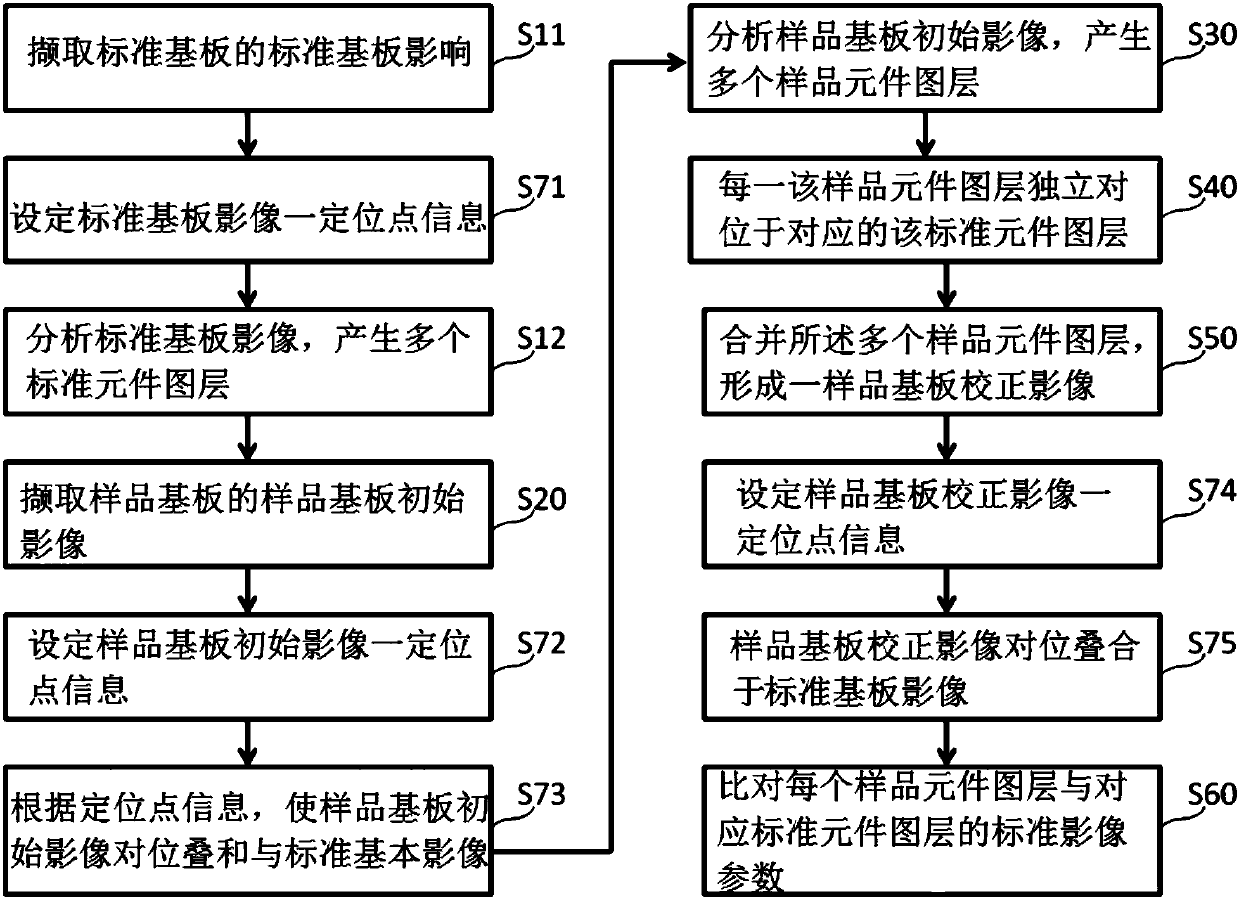

[0033] see figure 1 , which is a schematic flow diagram of the main steps of an embodiment of the image detection method for printed substrates of the present invention, as shown in the figure: the image detection method for printed substrates of the present invention includes the following steps:

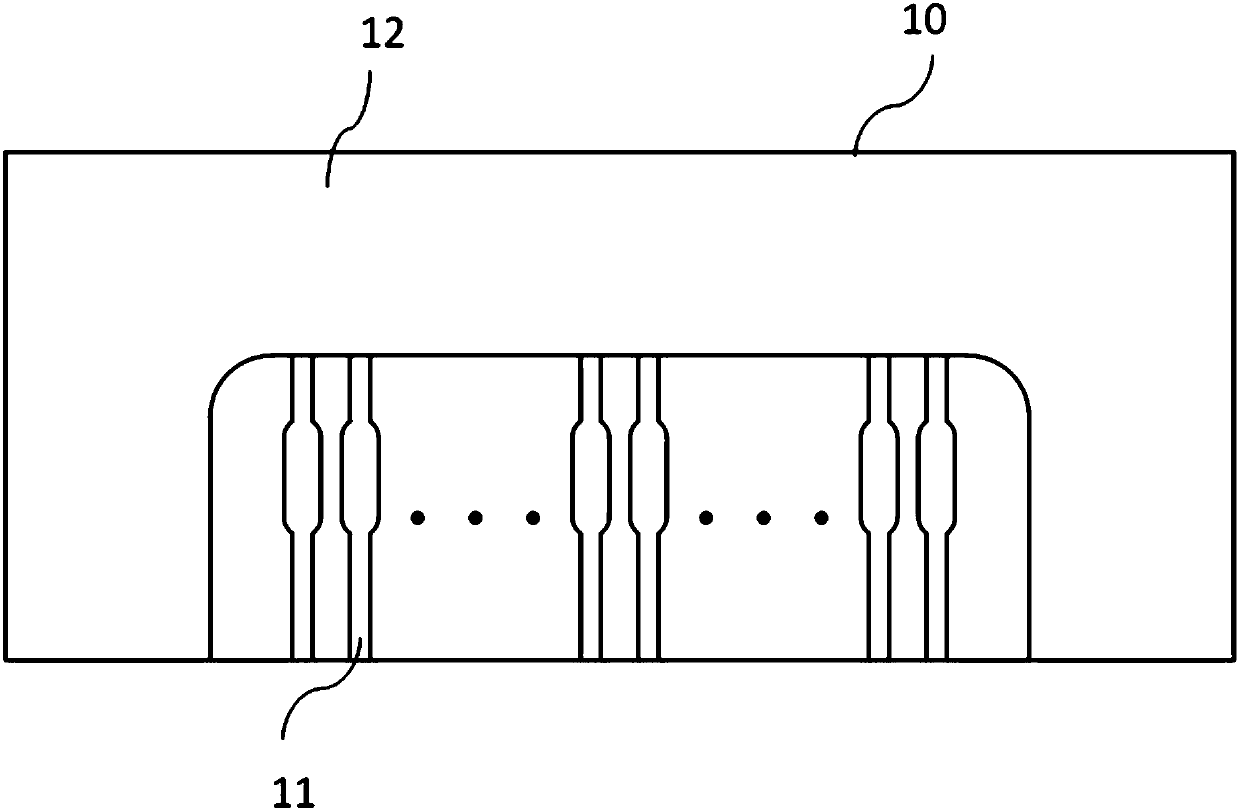

[0034] a) Obtaining a standard substrate image with multiple component areas and multiple standard component layers corresponding to each of the standard component areas, the standard component layer including a position information and at least one standard image parameter (step S10); wherein , the standard component area is the metal circuit layer area, the protective layer area, the through hole area or the solder mask area; the standard image parameter is the multi-primary color element value, and the multi-primary color element va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com