A kind of evaluation method of scr catalyst of selective catalytic reduction technology

A technology of SCR catalyst and evaluation method, which is applied in the evaluation field of selective catalytic reduction technology SCR catalyst, which can solve the problems of uneven exhaust, complicated operation, and unseen problems, and achieve the effect of convenient measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

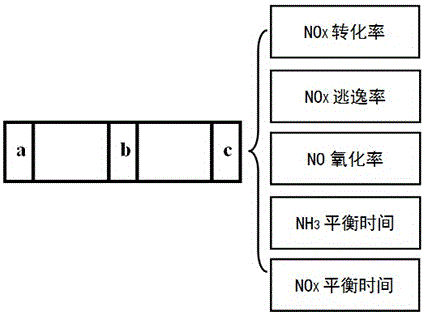

[0022] figure 1 It is a schematic diagram of catalyst sampling and a summary of evaluation indicators, where a, b, and c are the inlet section, middle section, and outlet section of the catalyst along the gas flow direction, and samples need to be taken at the same position from the center of the catalyst at these three places. The evaluation index is NO X Conversion rate, NH 3 escape rate, NO oxidation rate, NH 3 and NO X Balance time. Fresh catalysts are directly sampled and evaluated, and three samples of aged catalysts are taken as shown in the figure, and the average value is taken as the evaluation standard after evaluation.

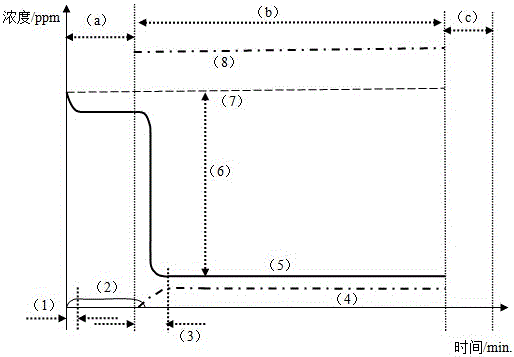

[0023] figure 2 For each temperature point, a schematic diagram of the specific implementation of the evaluation process, real-time continuous recording of NO X and NH 3 content changes over time. Wherein (a), (b), (c) are three steps ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com