Capacitive touch display panel

A capacitive touch and display panel technology, applied in the direction of electrical digital data processing, instruments, data processing input/output process, etc., can solve the problems of metal mesh structure easy to oxidize and corrode, reduce production efficiency, increase production cost, etc. , to achieve the effect of saving process, improving production efficiency and reducing reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0021] The orientations "up" and "down" referred to in the description of the present invention are only used to represent the relative orientation relationship; for the drawings in this specification, the upper part of the capacitive touch panel 10 is closer to the viewer, while the lower part is closer to the viewer. further away from the viewer.

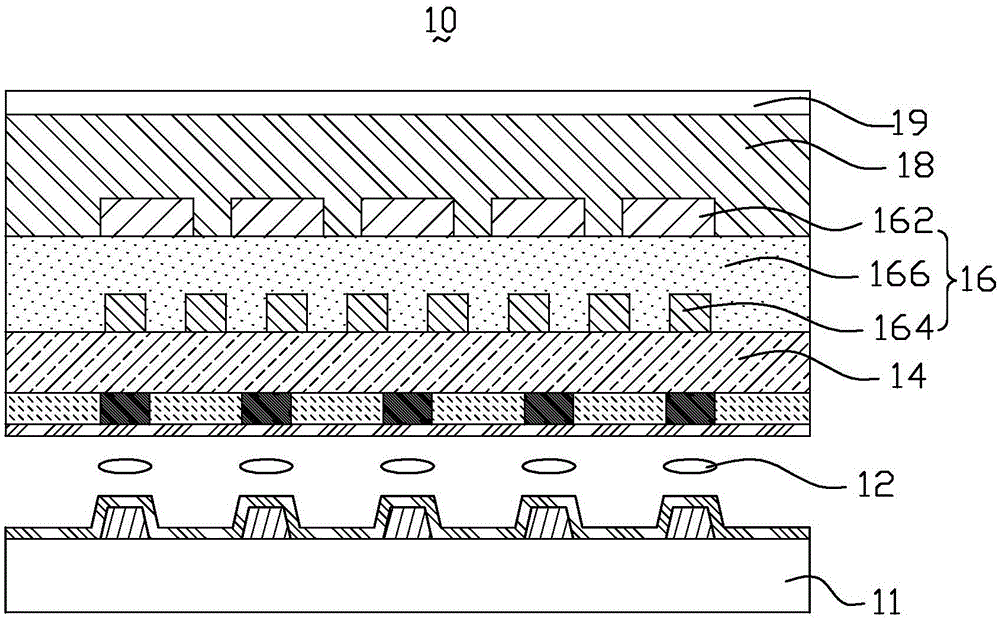

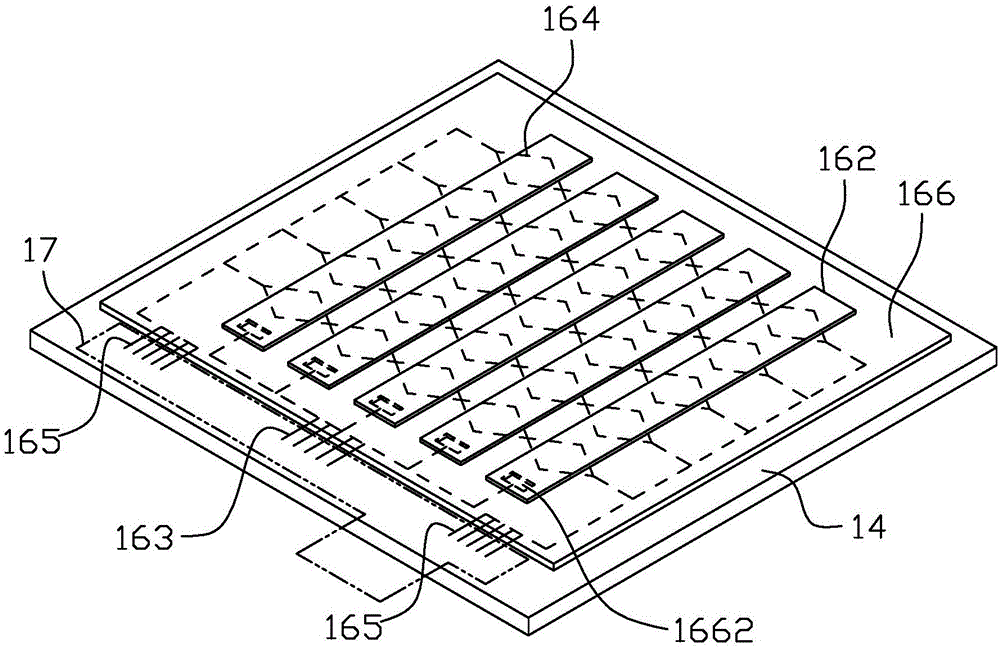

[0022] figure 1 is a schematic structural diagram of a capacitive touch display panel according to an embodiment of the present invention, figure 2 yes figure 1 The front view of the sensing electrode layer in , for details, please refer to figure 1 and figure 2 The capacitive touch display panel 10 of the present invention includes a thin film transistor (TFT) substrate 11, a liquid crystal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com