Colored glass and preparation method thereof, and colored solar cell module

A technology of solar cells and colored glass, applied in the field of solar cells, can solve the problems of single color of solar cell tiles and light pollution, and achieve the effect of reducing reflection and light pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

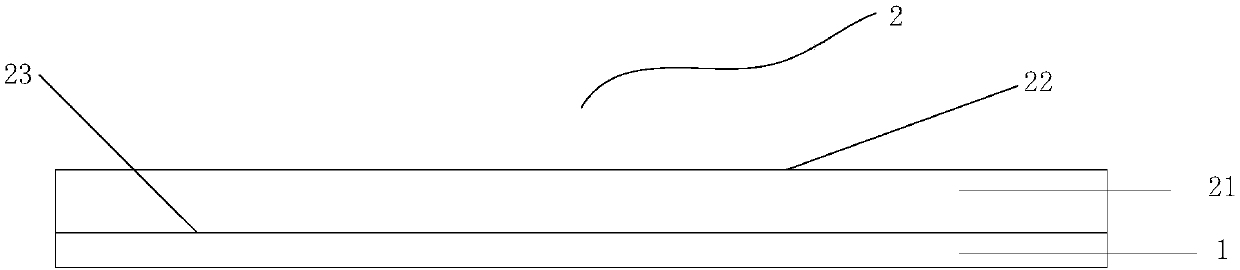

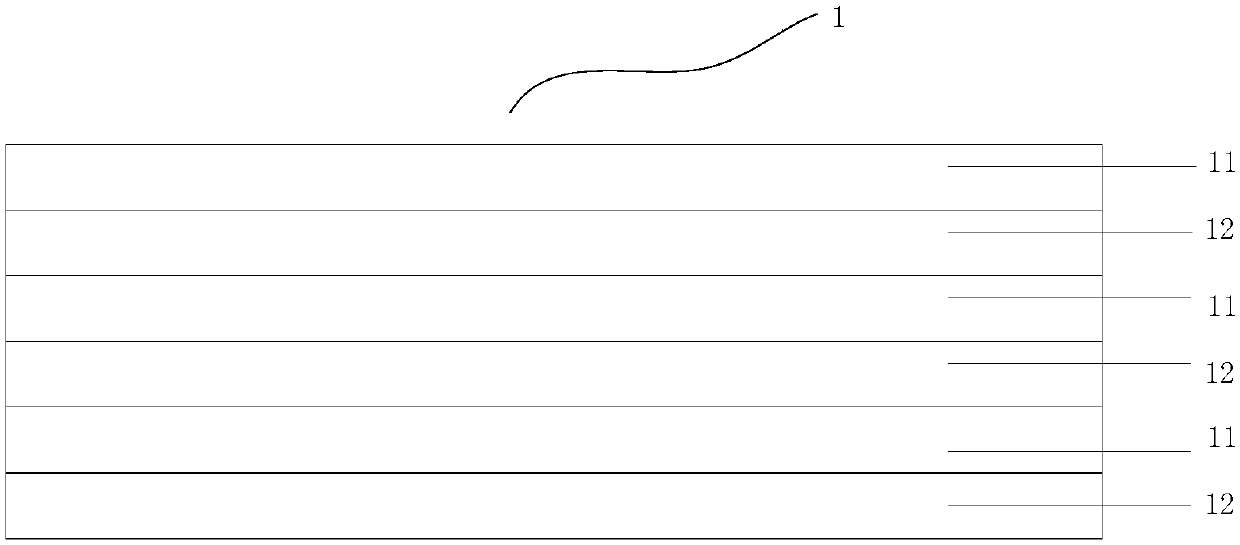

[0041] Such as figure 2 As shown, if the color film 1 is a red coating, the first film layer 11 and the second film layer 12 are provided with 6 layers, the first film layer 11 is a trititanium pentoxide layer, and the second film layer 12 is silicon dioxide Layers are alternately arranged with titanium pentoxide layers and silicon dioxide layers, the thickness of the first film layer 11 is set to 95-167nm, the thickness of the second film layer 12 is 130-192nm, and the total thickness is 890±30nm; Color shades are divided into multiple reds, so the red coating of the present application has a light color wavelength of 660±15 nanometers in the spectrum.

Embodiment 2

[0043] Such as figure 2 As shown, if the color film 1 is a golden coating, the first film layer 11 and the second film layer 12 are provided with 6 layers, the first film layer 11 is a trititanium pentoxide layer, and the second film layer 12 is silicon dioxide Layers are alternately arranged in the order of titanium pentoxide layers and silicon dioxide layers; the thickness of the first film layer 11 is set to 65-75nm, the thickness of the second film layer 12 is 90-180nm, and the total thickness is 760±30nm; due to the golden It is also divided into multiple golds according to the depth of the color, so the light color wavelength of the gold coating of the present application is 580±15 nanometers in the spectrum.

Embodiment 3

[0045] Such as figure 2 As shown, if the color film 1 is a blue coating, the first film layer and the second film layer are provided with 12 layers, the first film layer 11 is a silicon dioxide layer, and the second film layer 12 is a trititanium pentoxide layer. The sequence of silicon dioxide layer and trititanium pentoxide layer is arranged alternately; the thickness of the first film layer 11 is 70-140nm, the thickness of the second film layer 12 is 40-50nm, and the total thickness is 1080±30nm; There are multiple shades of blue, so the blue coating of the present application has a light color wavelength of 470±20 nanometers in the spectrum.

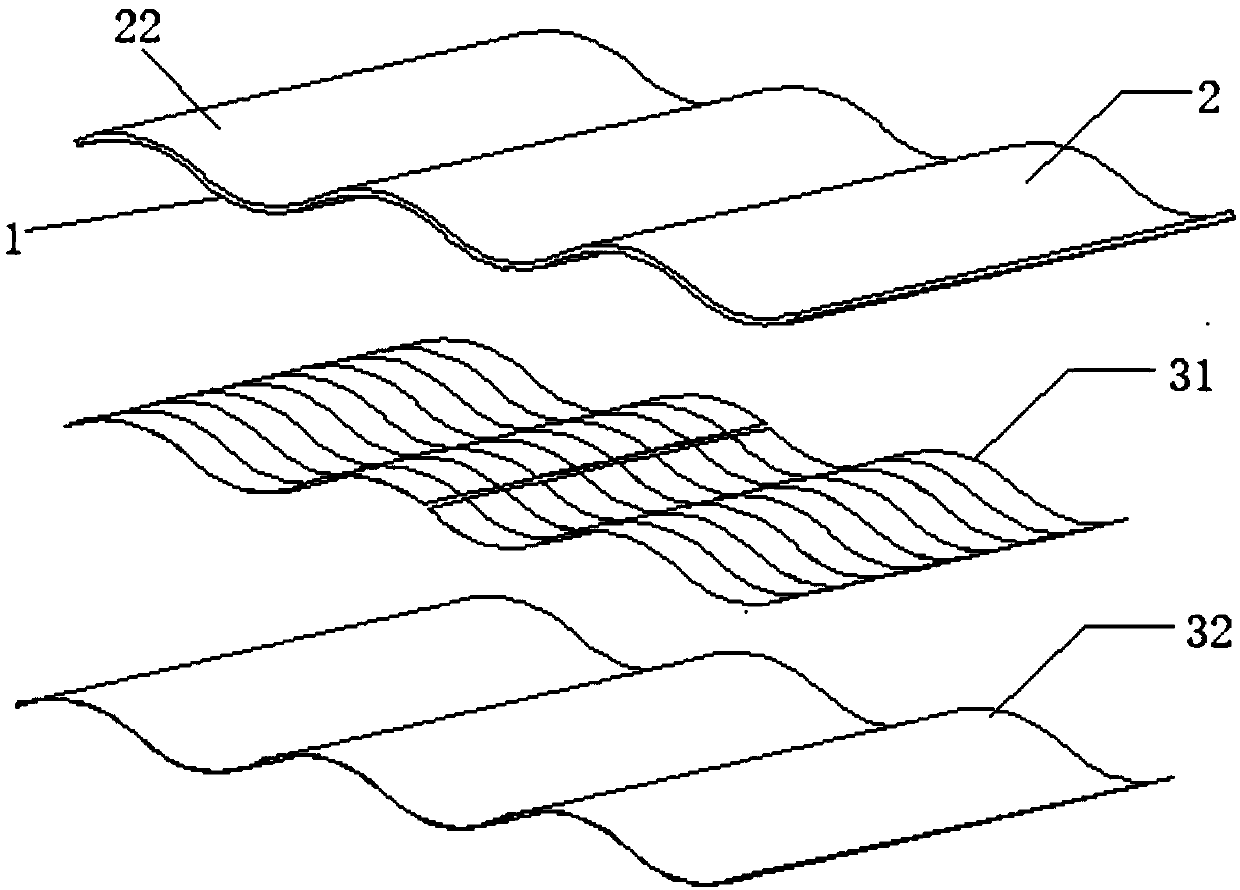

[0046] Such as image 3 As shown, the embodiment of the present application provides a colored solar cell assembly 3, including a back plate 32, a solar cell chip 31, and the above-mentioned colored glass 2 stacked in sequence; the back plate 32 is arranged on one side of the solar cell chip 31, The colored glass 2 is arranged on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com