Array substrate, preparation method thereof and display panel

An array substrate and display panel technology, which is applied in semiconductor/solid-state device manufacturing, instruments, semiconductor devices, etc., can solve the problems of lower contrast ratio of display panel, high reflectivity of display panel, and lower display effect of display panel, etc., so as to improve the display effect , Weaken the reflection and reduce the effect of reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

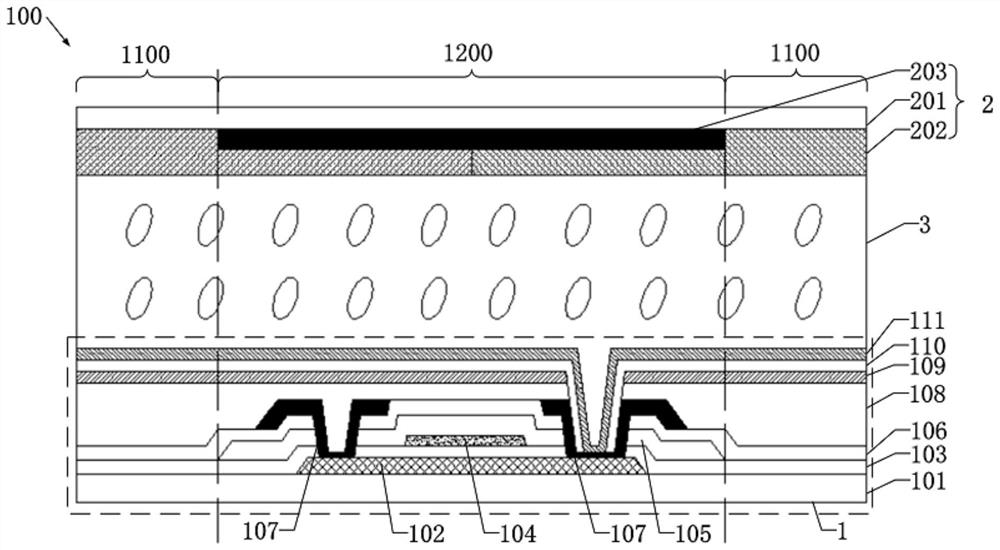

[0039] Such as figure 1 As shown, this embodiment provides a display panel 100 . The display panel 100 includes: an array substrate 1 , a color filter substrate 2 and a liquid crystal layer 3 .

[0040] Wherein, the array substrate 1 includes an opening area 1100 and a non-opening area 1200 . The array substrate 1 includes: a first substrate 101, an active layer 102, a gate insulating layer 103, a gate layer 104, a first interlayer insulating layer 105, a second interlayer insulating layer 106, a source-drain layer 107, a flat layer 108 , a common electrode layer 109 , a passivation layer 110 and a pixel electrode layer 111 .

[0041]Wherein, the material of the first substrate 101 is one or more of glass, polyimide, polycarbonate, polyethylene terephthalate and polyethylene naphthalate, thus the first The substrate 101 can have better impact resistance and can effectively protect the display device 100 . In this embodiment, the material of the first substrate 101 is glass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com