STL file format based main progressive forming direction determination method

A technology of incremental forming and file format, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of difficult to achieve part processing effect, difficult to control part forming thickness, etc., to improve strength and ensure smooth shaping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

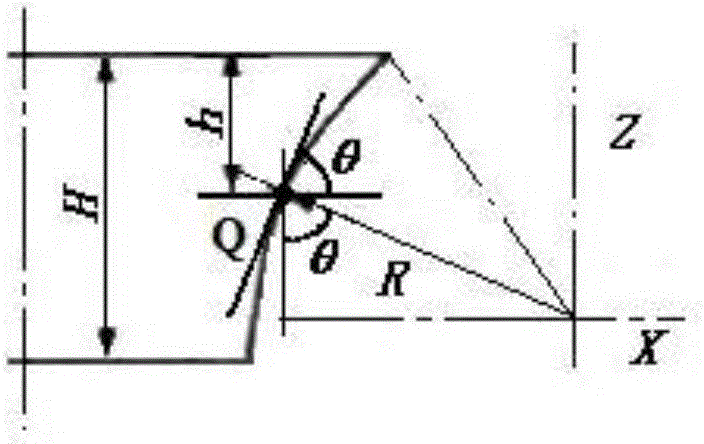

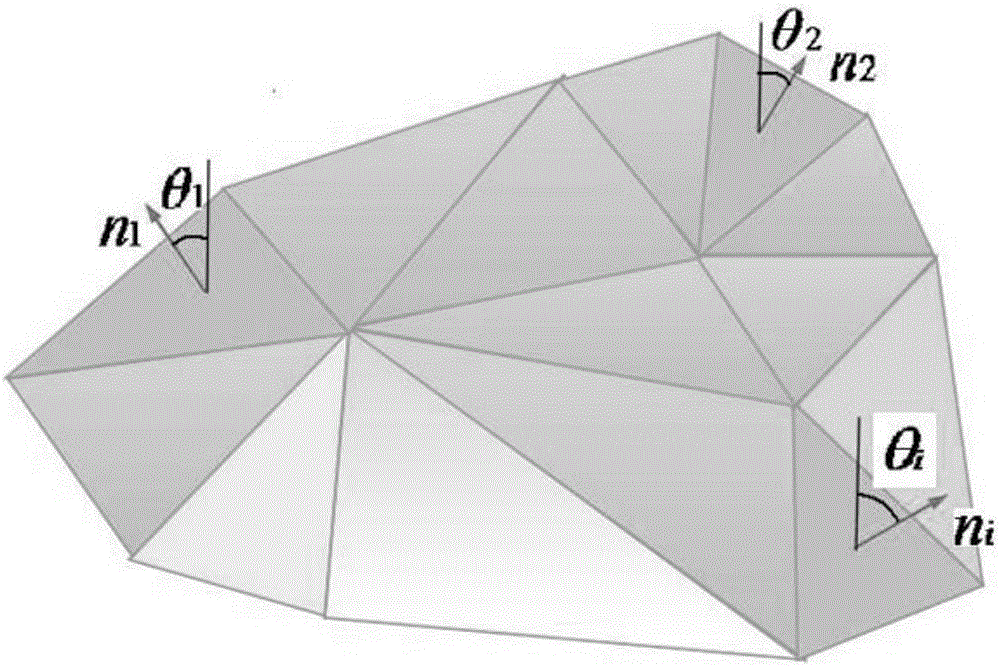

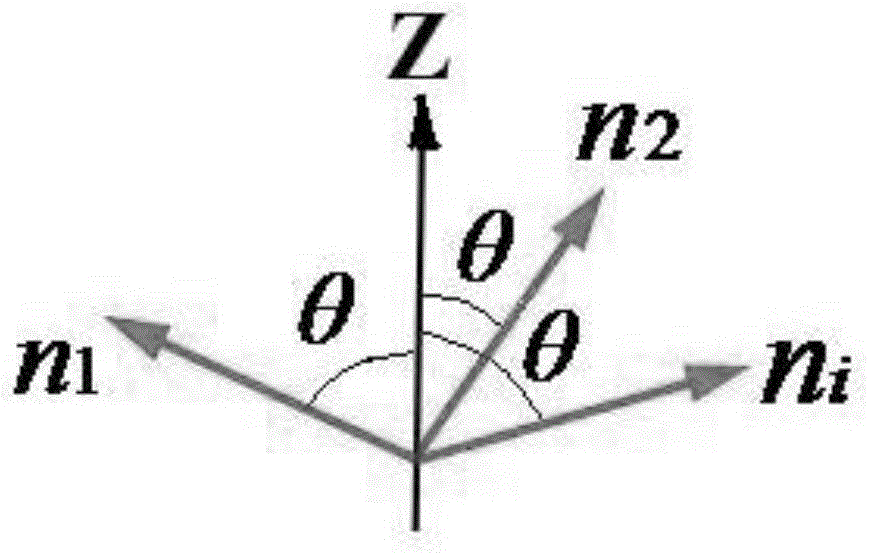

[0030] For incrementally formed parts, because there is no uniform standard for traditional processing placement, the main direction of forming is very random, and it is not easy to control the quality of formed parts. Based on the change of part thickness in incremental forming, it follows the cosine law t=t 0 *cosθ, where the forming angle θ is the angle between the normal vector of the forming part and the Z axis, using the external normal vector of the triangular patch in the STL file format, a method for judging the main direction of progressive forming is proposed, and a reasonable choice for progressive forming parts The forming position provides the basis.

[0031] This method discreti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com