Organic light-emitting diode device, fabrication method and display device

A technology of light-emitting diodes and manufacturing methods, which is applied in the fields of organic semiconductor devices, semiconductor/solid-state device manufacturing, and electric solid-state devices, and can solve problems such as the great impact on the life of OLED devices, chemical properties, and OLED device failure, and achieve improved Waterproof oxygen performance, improve waterproof performance, improve the effect of bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

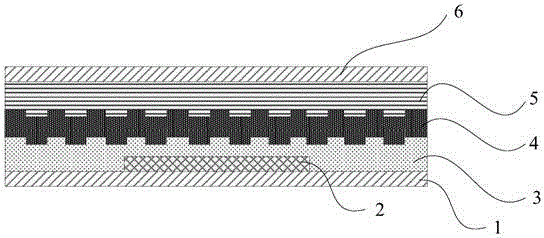

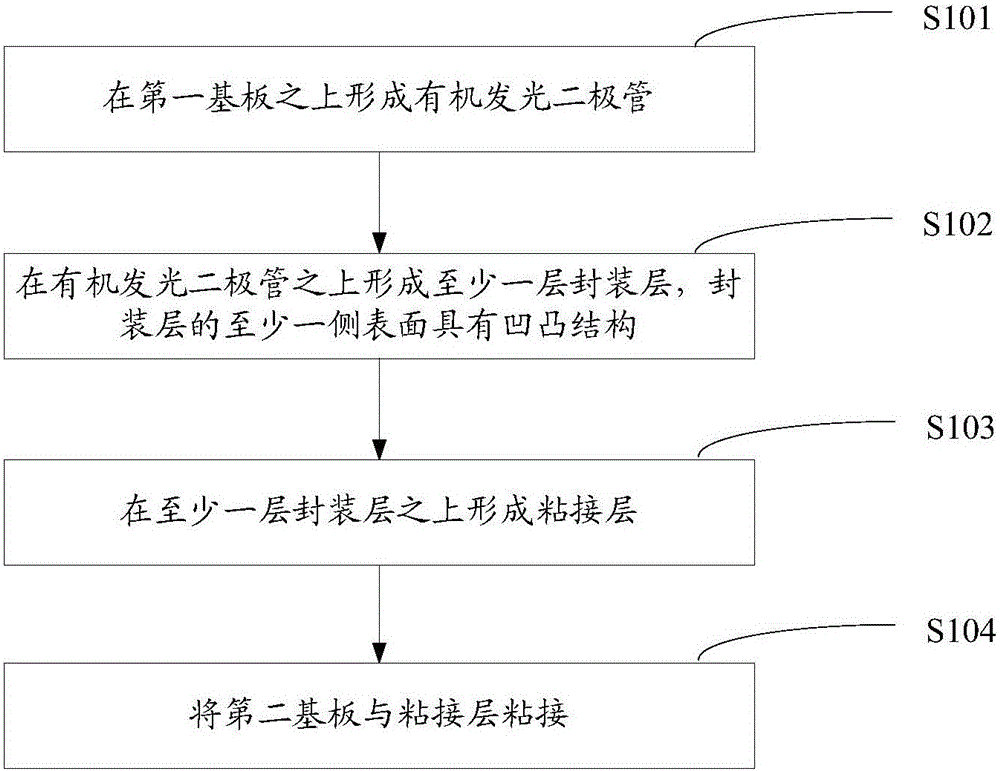

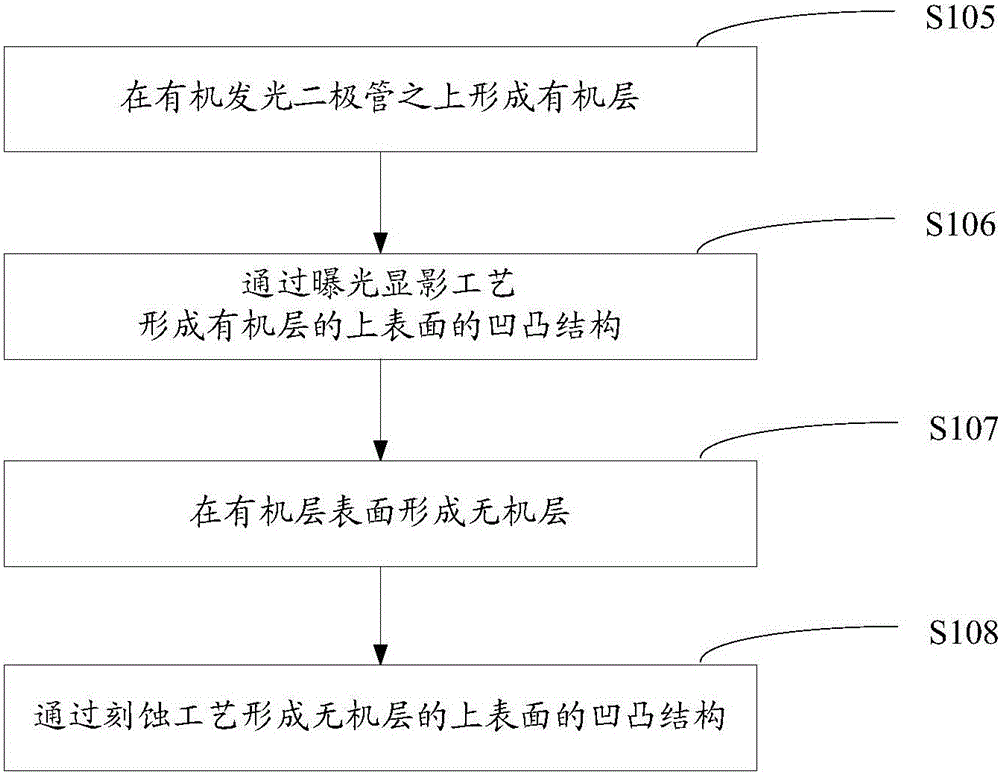

[0047] In order to improve the oxygen-proof performance of OLED devices, embodiments of the present invention provide an organic light-emitting diode device, a manufacturing method, and a display device. In the technical solution of the embodiment of the present invention, a concave-convex structure is designed on the surface of the encapsulation layer, and the concave-convex structure on the surface of the inorganic layer increases the surface area of the inorganic layer, thereby improving the performance of waterproofing oxygen; the concave-convex structure on the surface of the organic layer increases The contact area between the organic layer and the inorganic layer is improved, and the bonding effect is improved. Since the organic layer itself has water absorption, the waterproof performance of the organic layer is also improved. Therefore, compared with the prior art, this solution can reduce the damage to the OLED device by water vapor and oxygen in the air, and improv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com