Lithium ion solid conductor stable on metal lithium, preparation method of lithium ion solid conductor, and full-solid lithium secondary battery

A lithium ion and metal lithium technology, applied in the field of all-solid lithium secondary batteries, can solve problems such as the instability of metal lithium restricting development and application, loss of safe electrode active materials, low charge-discharge cycle efficiency, etc., and achieve lithium ion conductivity Improve, improve stability, improve the effect of ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The present invention also provides a kind of preparation method of lithium ion solid conductor material as shown in formula (I), comprises the following steps:

[0049] A) will Li 2 S, P 2 S 5 Mix and grind with M to obtain the initial material;

[0050] B) under the condition of inert gas, heat treatment is carried out to described initial material, obtain the lithium ion solid conductor material as shown in formula (I);

[0051] (100-x)(yLi2 S·zP 2 S 5 )·xM formula (I)

[0052] In formula (I): 0

[0053] M is lithium halide.

[0054] In the present invention, Li 2 S, P 2 S 5 Mix and grind with M to get the initial material. In the present invention, preferably carry out Li under the condition of inert gas 2 S, P 2 S 5 For weighing and mixing grinding with M, the inert gas is preferably nitrogen or argon. Among them, the Li 2 S and P 2 S 5 The molar ratio of Li is preferably 3:1, Li 2 S and P 2 S 5 The molar ratio of the mixed sulfi...

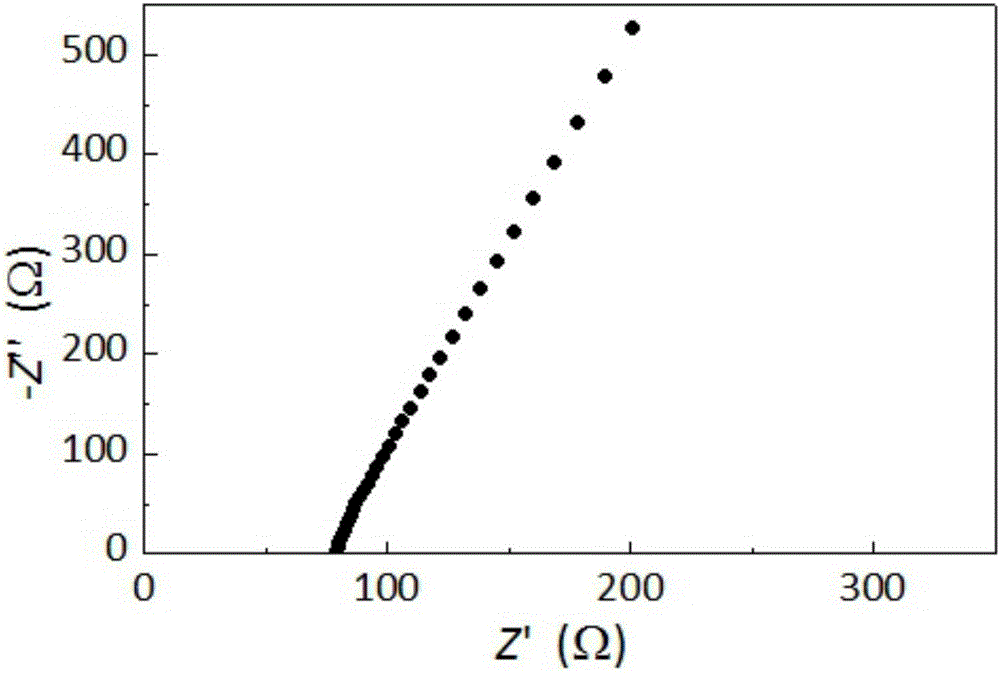

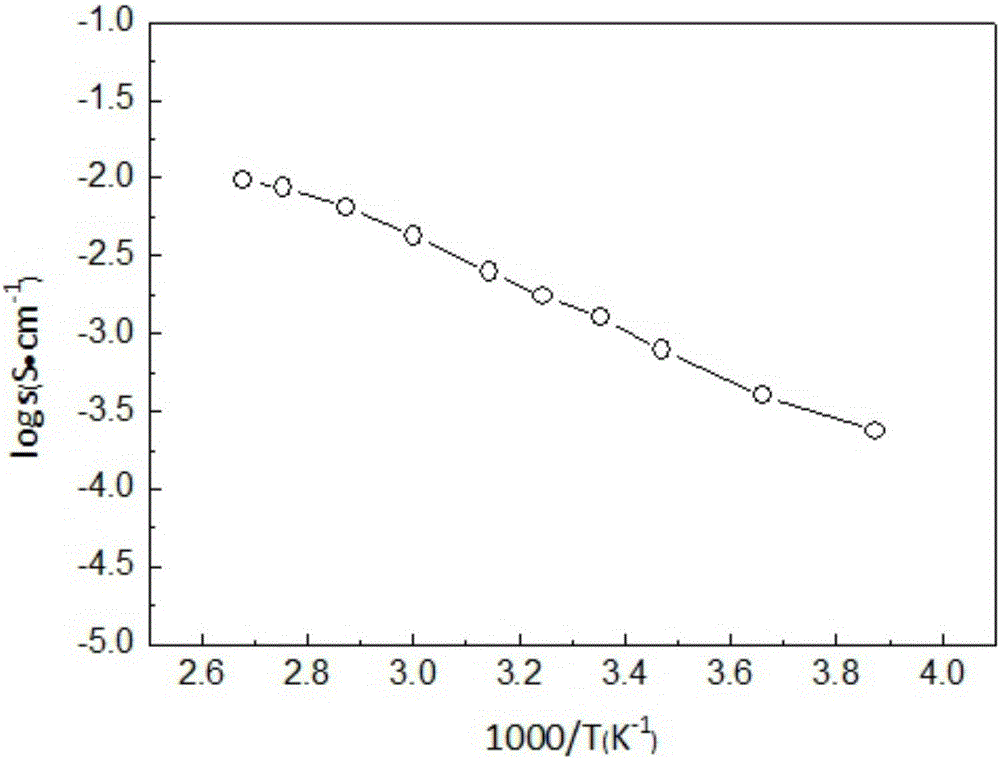

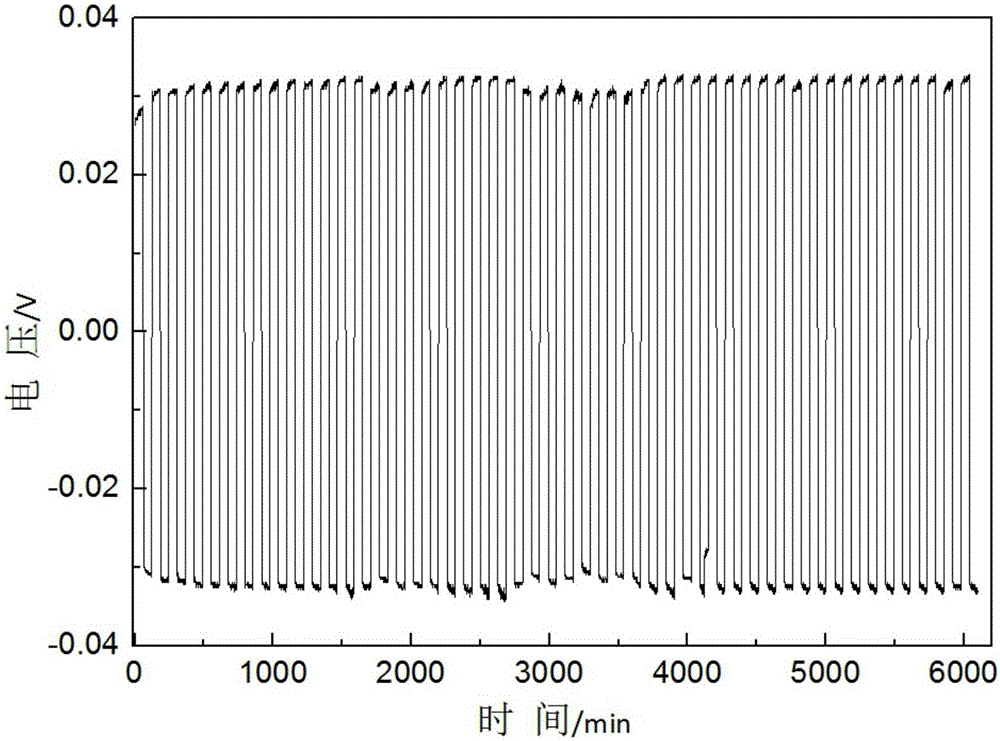

Embodiment 1

[0066] Under the protection of argon atmosphere, Li with a purity of more than 99% 2 S, P 2 S 5 After weighing according to the molar ratio of 75:25, press (75Li 2 S·25P 2 S 5 ): LiI=90:10 molar ratio is added LiI, under the condition of water content less than 10ppm with 500rpm rotating speed grinds and mixes evenly, under the condition of 45:1 ball-to-material ratio condition, after high-energy ball milling 12h, obtain powder primary material, take out powder primary material After the material is ground finely and evenly, it is pressed into tablets with a pressure of 10 MPa to obtain a flake-like raw material, and the flake-like raw material is loaded into a sintering mold. Heat the sintering mold equipped with the above flake raw material to 250°C at a heating rate of 2°C / min, keep it warm for 2h, cool down to room temperature with the furnace, take out the flake sintered product under the condition that the water content is less than 100ppm, and grind it evenly to obt...

Embodiment 2

[0071] Under the protection of argon atmosphere, Li with a purity of more than 99% 2 S, P 2 S 5 After weighing according to the molar ratio of 75:25, press (75Li 2 S·25P 2 S 5 ): LiI=95:5 in molar ratio, add LiI, grind and mix uniformly at 200rpm under the condition of water content less than 10ppm, and obtain the primary powder after high-energy ball milling under the condition of 40:1 ball-to-material ratio for 18h, take out the primary powder After the material is ground finely and evenly, it is pressed into tablets with a pressure of 10 MPa to obtain a flake-like raw material, and the flake-like raw material is loaded into a sintering mold. Heat the sintering mold equipped with the above-mentioned flaky raw material to 300°C at a heating rate of 1°C / min, keep it warm for 4h, cool down to room temperature with the furnace, take out the flaky sintered product under the condition that the water content is less than 100ppm, and grind it evenly to obtain Powder all-solid l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com