Polarizing element or polarizing plate for display device with blue light emitting element

A polarizing element and polarization technology, which is applied in the field of polarizing elements or polarizers for organic electroluminescence, and can solve problems such as low transmittance, poor durability of iodine-based polarizers, and reduced brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0113] [chemical formula 12]

[0114]

[0115] [Compound Example 2]

[0116] [chemical formula 13]

[0117]

[0118] [Compound Example 3]

[0119] [chemical formula 14]

[0120] [Compound Example 4]

[0121] [chemical formula 15]

[0122]

[0123] [Compound Example 5]

[0124] [chemical formula 16]

[0125]

[0126] Next, more specific examples of the azo compound represented by formula (2) will be shown in the form of the following free acid.

[0127] [Compound Example 6]

[0128] [chemical formula 17]

[0129]

[0130] [Compound Example 7]

[0131] [chemical formula 18]

[0132]

[0133] [Compound Example 8]

[0134] [chemical formula 19]

[0135]

[0136] [Compound Example 9]

[0137] [chemical formula 20]

[0138]

[0139] [Compound Example 10]

[0140] [chemical formula 21]

[0141]

example 11

[0143] [chemical formula 22]

[0144]

[0145] [Compound Example 12]

[0146] [chemical formula 23]

[0147]

[0148] [Compound Example 13]

[0149] [chemical formula 24]

[0150] [Compound Example 14]

[0151] [chemical formula 25]

[0152]

[0153] Next, more specific examples of the azo compound represented by formula (3) will be shown in the form of the following free acid.

[0154] [Compound Example 15]

[0155] [chemical formula 26]

[0156]

[0157] [Compound Example 16]

[0158] [chemical formula 27]

[0159]

[0160] [Compound Example 17]

[0161] [chemical formula 28]

[0162]

[0163] [Compound Example 18]

[0164] [chemical formula 29]

[0165]

[0166] [Compound Example 19]

[0167] [chemical formula 30]

[0168]

[0169] [Compound Example 20]

[0170] [chemical formula 31]

[0171]

[0172] [Compound Example 21]

[0173] [chemical formula 32]

[0174]

[0175] [Compound Example 22]

[0176] [chemical formula 33] ...

Embodiment 1

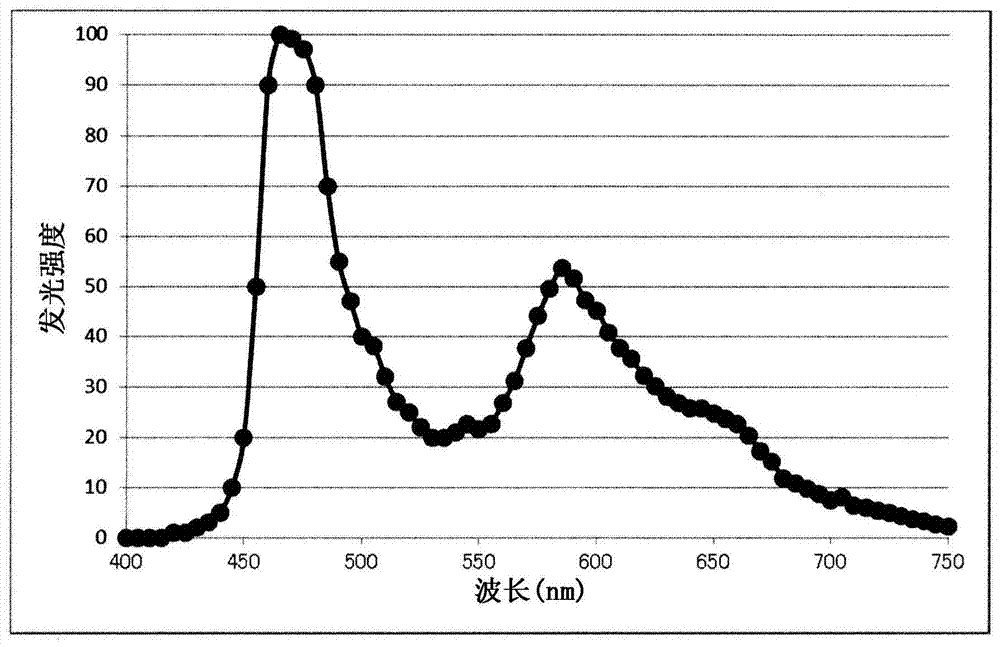

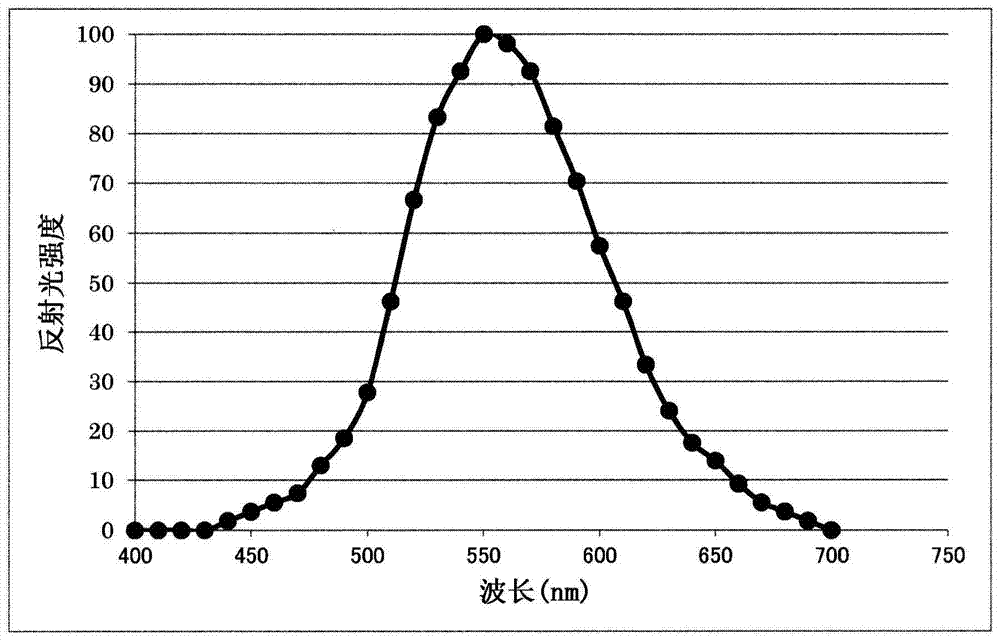

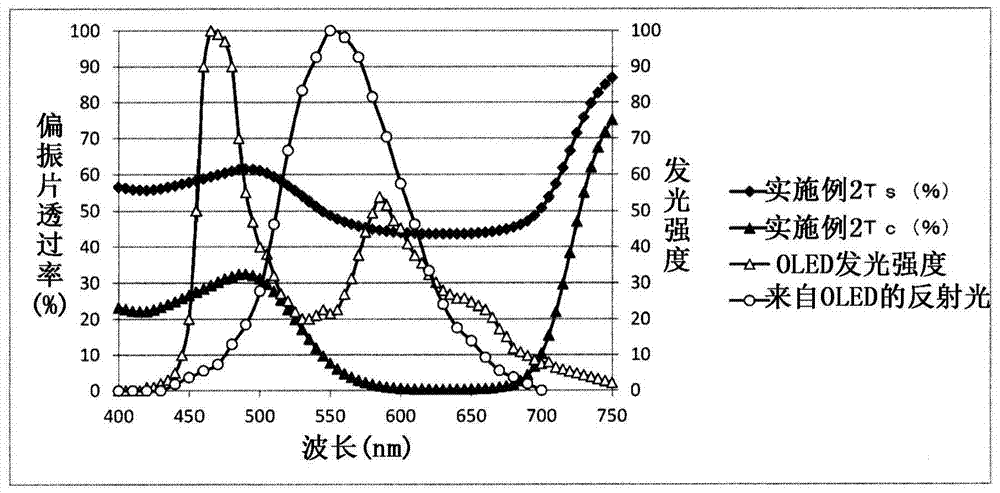

[0270] A polyvinyl alcohol film (VF-XS manufactured by Kuraray Co., Ltd.) with an average degree of polymerization of 99% or higher and an average degree of polymerization of 2400 was soaked in warm water at 45° C. for 2 minutes, subjected to swelling treatment, and stretched to 1.30 times. The swelling-treated film was soaked in an aqueous solution at 45° C. containing 1500 parts by weight of water, 1.5 parts by weight of sodium tripolyphosphate, and 0.15 parts by weight of the dye described in Example 2 of JP-A-09-132726, and dyed. Stretching treatment was performed for 5 minutes in a 50° C. aqueous solution containing 30.0 g / L of boric acid while stretching the dyed film 5.0 times. Keep the tense state of the film obtained by the boric acid treatment, and wash in water at 30°C for 20 seconds, and dry the obtained film at 70°C for 9 minutes to obtain a transmittance of about 50% according to the present invention. the polarizing element. The dried polarizing element and an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com