Crop straw mattress

A crop straw and mattress technology, applied to mattresses, spring mattresses, stuffed mattresses, etc., can solve the problems of low cost of sponge mattresses, limited supply of raw materials, insufficient hygiene and safety, etc., to achieve easy weaving, good elasticity, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

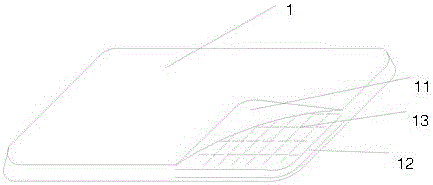

[0017] A crop straw mattress, which is used for bedding the bottom layer of a steel wire bed. The straw mattress 1 includes a braided layer 11, a lining layer 12 and a suture rope 13. The braided layer is woven from corn bale, and braided around it. shape; the lining core layer 12 is crushed corn stalks with a fiber length of not less than 1 cm, and a thickness of 5 cm; the suture rope 13 is a hemp rope with a diameter of 0.2 cm, which is distributed in a grid shape and interspersed up and down. The core layer 12 is stitched with the upper and lower braided layers 11 of the straw mattress; one side of the braided layer 11 is provided with an opening for filling the core layer 12, and after the core layer 12 is filled, the corn bale is used to cover the Open weave seams.

Embodiment 2

[0019] A crop straw mattress, which is used for bedding the bottom layer of a steel wire bed. The straw mattress 1 includes a braided layer 11, a lining layer 12 and a suture rope 13. The braided layer is woven from corn bale, and braided around it. shape; the lining core layer 12 is crushed corn stalks with a fiber length of not less than 1 cm, and a thickness of 3 cm; the suture rope 13 is a hemp rope with a diameter of 0.3 cm, which is distributed in a grid shape and interspersed up and down. The core layer 12 is stitched with the upper and lower braided layers 11 of the straw mattress; one side of the braided layer 11 is provided with an opening for filling the core layer 12, and after the core layer 12 is filled, the corn bale is used to cover the Open weave seams. The corn stalks and corn stalks are all subjected to sulfur fumigation, bleaching, and high-temperature steam cooking at 105° C.-110° C. for 30-45 minutes before use.

Embodiment 3

[0021] A crop straw mattress, which is used for bedding the bottom layer of a steel wire bed. The straw mattress 1 includes a braided layer 11, a lining layer 12 and a suture rope 13. The braided layer is braided by straw, and braided around; The lining core layer 12 is crushed rice straw with a fiber length of not less than 1 cm, and the thickness is 2 cm; the suture rope 13 is a cotton rope with a diameter of 0.5 cm, which is distributed in a grid shape and interspersed up and down. The layer 12 is stitched with the upper and lower braided layers 11 of the straw mattress; one side of the braided layer 11 is provided with an opening for filling the core layer 12, and after the core layer 12 is filled, corn bale is used to weave and sew the opening . The rice straw and the crushed rice straw are all subjected to sulfur fumigation and bleaching before use, and subjected to high-temperature steam cooking at 105°C-110°C for 30-45 minutes; spray 0.01-0.5% of chlorofluorochrysanthe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com