Innovative drug excipient compressible sucrose and preparation method thereof

A technology of pharmaceutical excipients and sucrose, which is applied in the field of compressible sucrose and its preparation, and can solve problems affecting taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

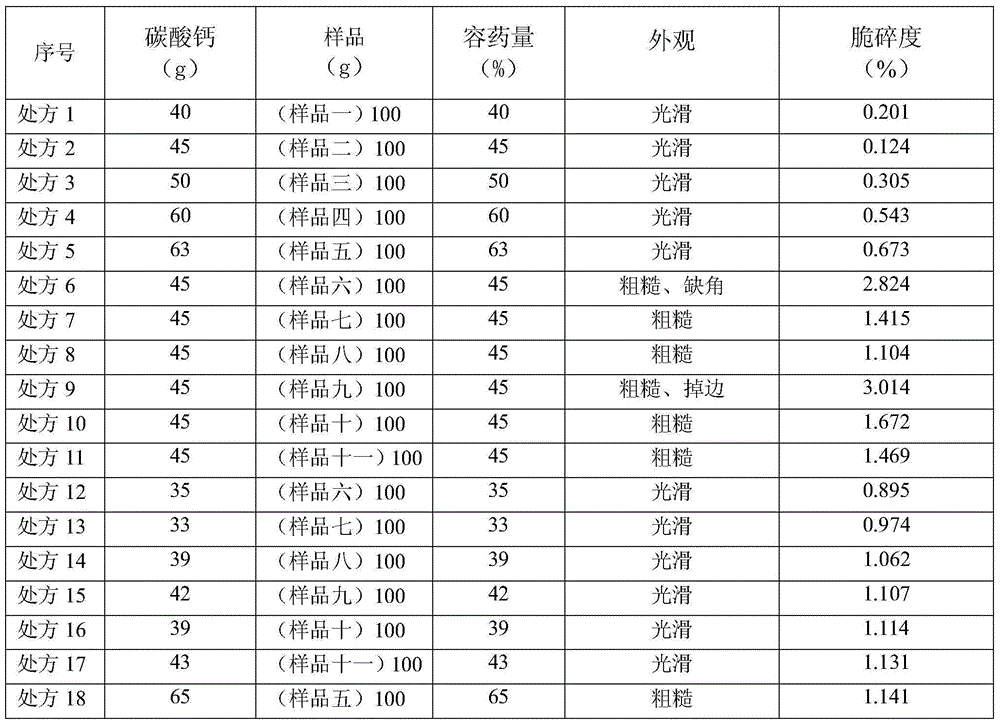

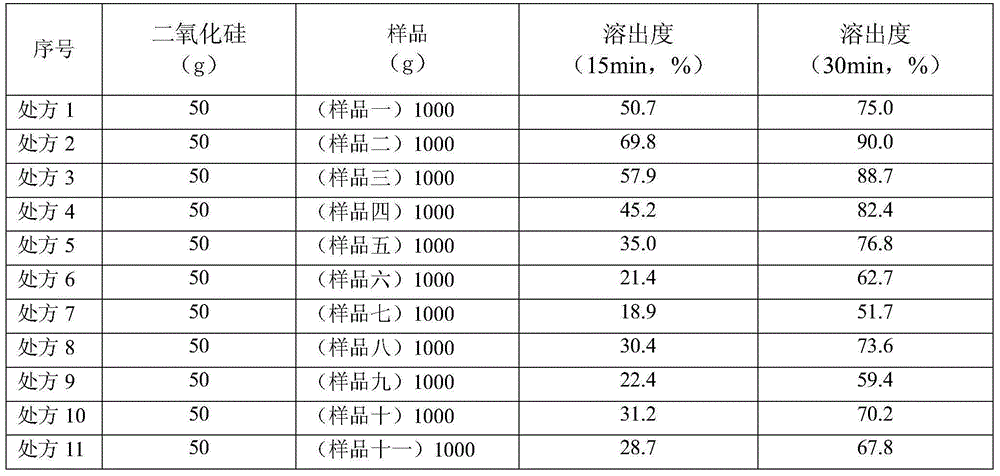

Examples

Embodiment 1

[0012] Components:

[0013] Material name

Proportion(%)

Weight (g)

sucrose

79.8

7980

3.7

370

14.0

1400

silica

2.5

250

[0014] Preparation:

[0015] (1) take by weighing 7980g sucrose and 370g dextrin of recipe quantity, standby;

[0016] (2) Add the prescribed amount of sucrose and dextrin into purified water at 55°C, stir evenly, prepare a solution with a solid content of 8%, cool down to 36°C, and set aside;

[0017] (3) Mix 1400g of starch and 250g of silicon dioxide in the prescription amount evenly, slowly add to the above (2), stir evenly, and set aside;

[0018] (4) Cool the material in the above (3) to 5°C, crystallize under stirring at 80 rpm for 2 hours, collect the filter cake by suction filtration, wash the filter cake with 0°C purified water 10 times the total amount of feed, and dry at 40°C , to obtain the compressible sucrose of the present invention.

Embodiment 2

[0020] Components:

[0021] Material name

Proportion(%)

Weight (g)

sucrose

94.2

9420

2.5

250

starch

1.5

150

silica

1.8

180

[0022] Preparation:

[0023] (1) take by weighing 9420g sucrose and 250g dextrin of recipe quantity, standby;

[0024] (2) Add the prescribed amount of sucrose and dextrin into purified water at 68°C, stir evenly, prepare a solution with a solid content of 16%, cool down to 42°C, and set aside;

[0025] (3) Mix 150g of starch and 180g of silicon dioxide in the prescription amount evenly, slowly add to the above (2), stir evenly, and set aside;

[0026] (4) Cool the material in the above (3) to 9°C, crystallize under stirring at 110 rpm for 4 hours, collect the filter cake by suction filtration, wash the filter cake with 5°C purified water 10 times the total amount of feed, and dry at 58°C , to obtain the compressible sucrose of the present invention.

Embodiment 3

[0028] Components:

[0029] Material name

Proportion(%)

Weight (g)

sucrose

80

8000

14.5

1450

starch

4

400

silica

1.5

150

[0030] Preparation:

[0031] (1) take by weighing 8000g sucrose and 1450g dextrin of recipe quantity, standby;

[0032] (2) Add the prescribed amount of sucrose and dextrin into purified water at 60°C, stir evenly, prepare a solution with a solid content of 12%, cool to 40°C, and set aside;

[0033] (3) Mix 400g of starch and 150g of silicon dioxide in the prescription amount evenly, slowly add to the above (2), stir evenly, and set aside;

[0034] (4) Cool the material in the above (3) to 7°C, crystallize under stirring at 90 rpm for 3 hours, collect the filter cake by suction filtration, wash the filter cake with purified water at 3°C 10 times the total amount of input, and dry at 50°C , to obtain the compressible sucrose of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com