Automatic production line for powdered activated carbon regeneration

An automatic production line, powdered activated carbon technology, applied in the direction of filter regeneration, other chemical processes, combustible gas purification, etc., can solve the problems of production shutdown, impact on promotion, etc., to achieve health assurance, strong practicability, and high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with embodiment the present invention will be further described.

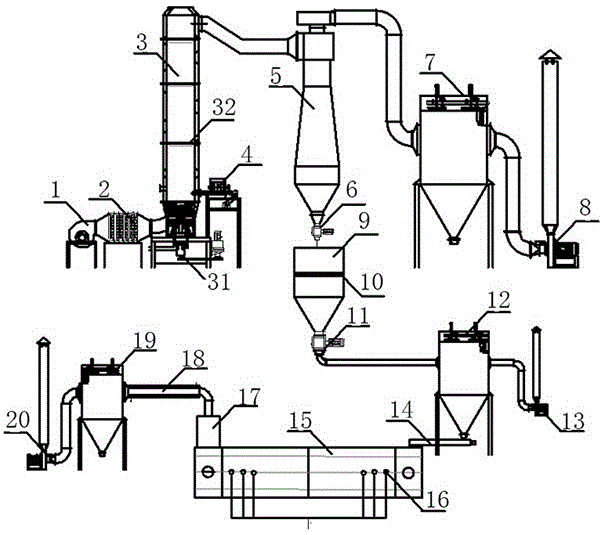

[0020] like figure 1 Shown, a kind of automatic production line of powdery activated carbon regeneration comprises heating combustion furnace 2, and described heating combustion furnace 2 is connected with drier 3, is connected with screw feeder 4 on the side wall of drier 3 bottom, and the side wall of drier 3 The top is connected to the cyclone separator 5 through the pipeline, the bottom of the cyclone separator 5 is connected to the desander 9, the bottom of the desander 9 is connected to the second pulse bag filter 12, and the bottom of the second pulse bag filter 12 passes through the feeding screw The device 14 is connected to one end of the gasifier 15 , and the other end of the gasifier 15 is connected to a flue gas cooling channel 17 , and the flue gas cooling channel 17 is connected to a pulse dust collector 19 through a condensation pipe 18 .

[0021] The heating and com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com