A Punch Manipulator for Reprocessing Rotor Punching

A technology of rotor punching and manipulators, applied in manipulators, metal processing equipment, manufacturing tools, etc., can solve the problems of inability to determine the quantity of feed materials, many pauses, etc., and achieve the effect of high yield and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

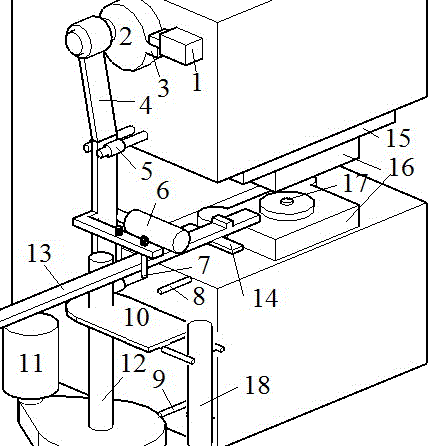

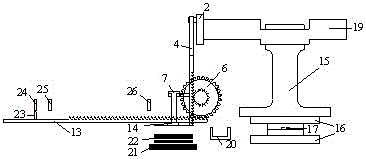

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific examples.

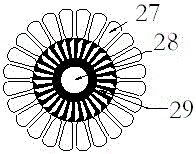

[0024] Transmission device of the present invention such as figure 2 As shown, the connection diagram of each part is shown in Figure 3-Figure 4 As shown: the punch slider 15 is connected to the main rotating shaft 19 and the upper half of the mold 16, the brake wheel 2 is located at the left end of the main rotating shaft 19, the transmission rod 4 is connected to the brake wheel 2, and the permanent magnet sucker is located on a branch of the transmission rod 4 , the branch of the permanent magnetic sucker 7 and the transmission rod 4 is not completely fixed, but has a certain range of motion up and down, such as image 3 and Figure 4 As shown, when the main rotating shaft 19 rotates, it drives the slider 15 and the mold 6 to move up and down, and simultaneously the transmission rod 4 and the permanent magnet sucker 7 also move up and dow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com