Plate chain type conveyor

A conveyor and plate chain technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of increased cleaning or disinfection of equipment and materials, increased energy consumption, and easy wear and tear of parts, etc., to achieve reduction The risk of cross-contamination, the effect of less energy consumption and low friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

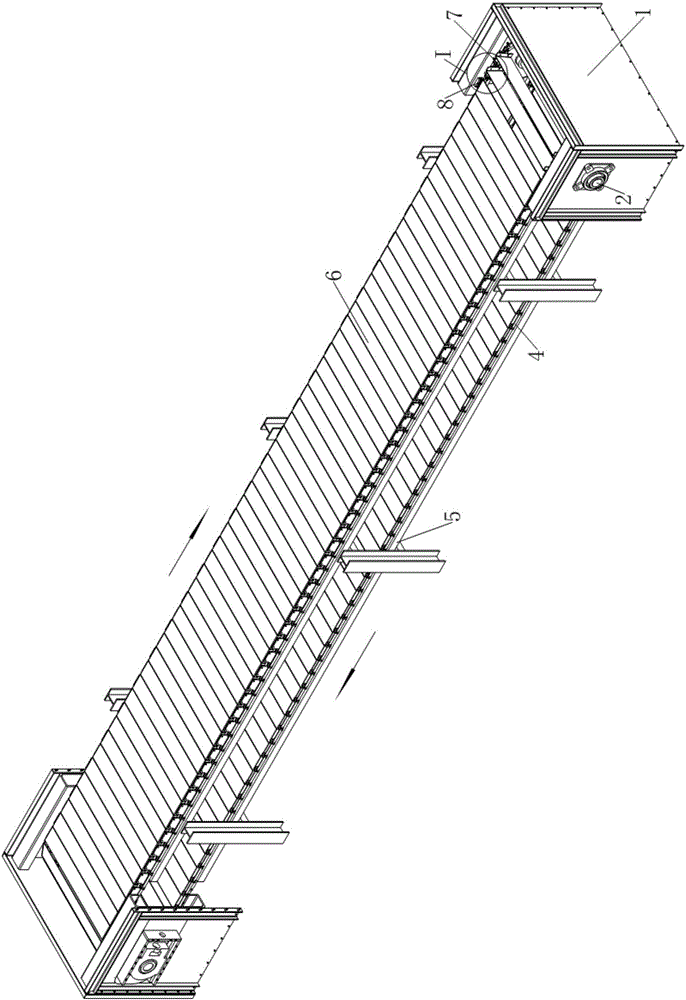

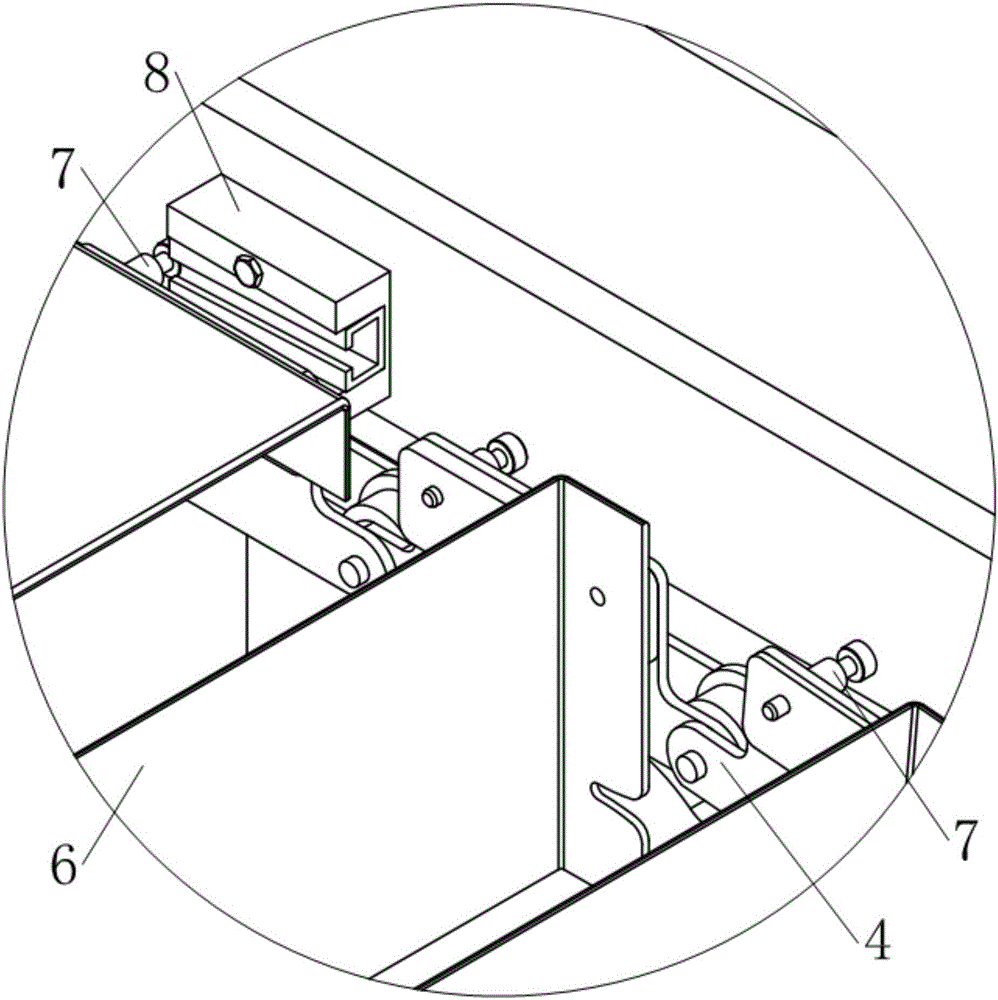

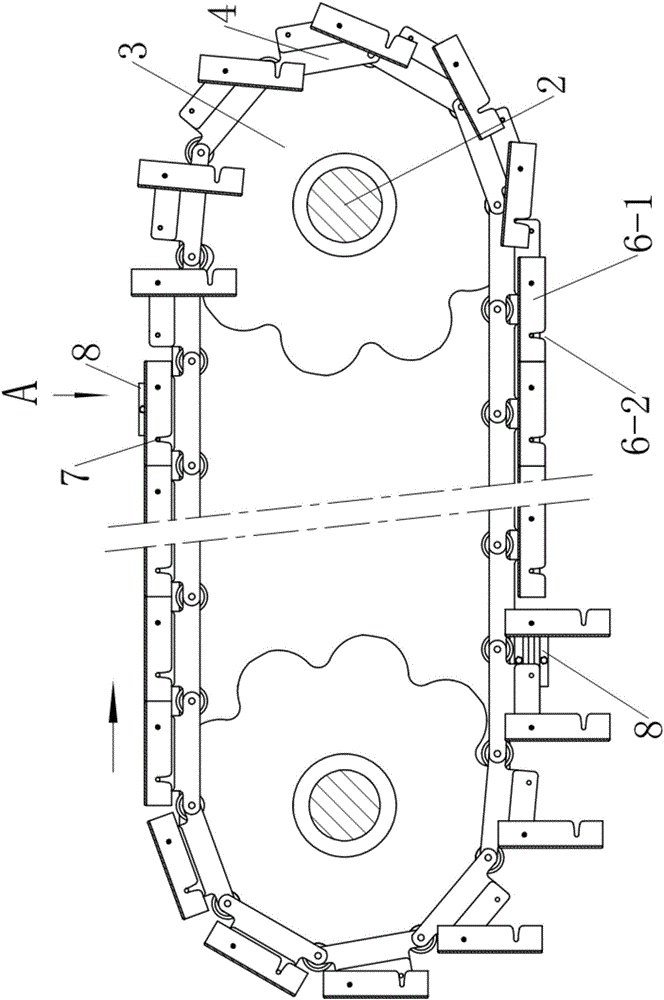

[0021] see Figure 1~2 , in this example, the conveyor includes a frame, two pairs of sprockets 3 and a conveyor belt that is wound around the two pairs of sprockets 3; the frame is composed of the conveyor heads 1 at both ends and the conveyor chain support 5 at the bottom of the conveyor belt; The conveyor belt is composed of two conveyor chains 4 wound in parallel on two pairs of sprockets 3 and a set of material plates 6 straddling the two conveyor chains 4 .

[0022] see figure 1 with 3 , the machine head 1 is spliced by section steel and steel plate, the support shaft 2 is straddled on the box body on both sides of the machine head 1, and two sprockets 3 are fixed on each support shaft 2. The two conveyor chains 4 are respectively wound on the two sprockets 3 on the same side of the two supporting shafts 2 .

[0023] see Figure 3-6 , the conveyor chain 4 is composed of an outer chain plate 4-1, an inner chain plate 4-2 and a roller 4-5, wherein the outer chain pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com