Formula for osmotic agent

A penetrant and formula technology, applied in the field of penetrant formula, can solve the problems of poor biodegradability, affecting the use effect, white powder spots and other problems, and achieve the effect of simple production operation, improved production efficiency and good gross effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

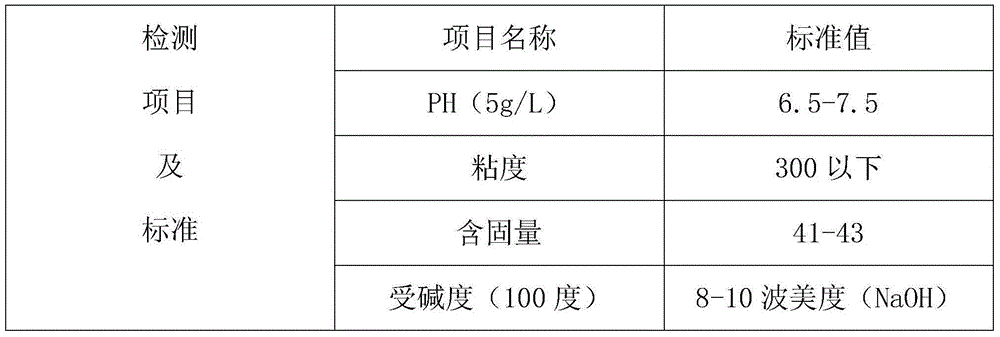

Image

Examples

Embodiment 1

[0012] Penetrant formula, the following components are taken according to the number of parts: 40 parts of water, 16.5 parts of fatty alcohol polyoxyethylene ether, 26.5 parts of sodium secondary alkylsulfonate, and 17 parts of sodium lauryl alcohol ether sulfate.

[0013] Preparation method: Put fatty alcohol polyoxyethylene ether into a container filled with water and stir evenly, where the water temperature is 70°C, then add sodium secondary alkylsulfonate, stir evenly, then add sodium lauryl alcohol ether sulfate, stir uniform, the penetrant of the present invention can be obtained.

Embodiment 2

[0015] Penetrant formula, the following components are taken by parts: 42 parts of water, 17 parts of fatty alcohol polyoxyethylene ether, 25.5 parts of sodium secondary alkylsulfonate, and 15.5 parts of sodium lauryl alcohol ether sulfate.

[0016] The preparation method is the same as in Example 1.

Embodiment 3

[0018] Penetrant formula, the following components are taken by parts: 42.2 parts of water, 15.8 parts of fatty alcohol polyoxyethylene ether, 25.8 parts of sodium secondary alkylsulfonate, and 16.2 parts of sodium lauryl alcohol ether sulfate.

[0019] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com